Closed electroosmosis drive method and electroosmosis drum

An electroosmotic-driven, closed-type technology, applied in the field of electrochemistry, can solve the problems of contamination by the transmission fluid, clogging of air bubbles, inconvenient use, etc., and achieve the effect of stable pH value, avoiding clogging of air bubbles, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

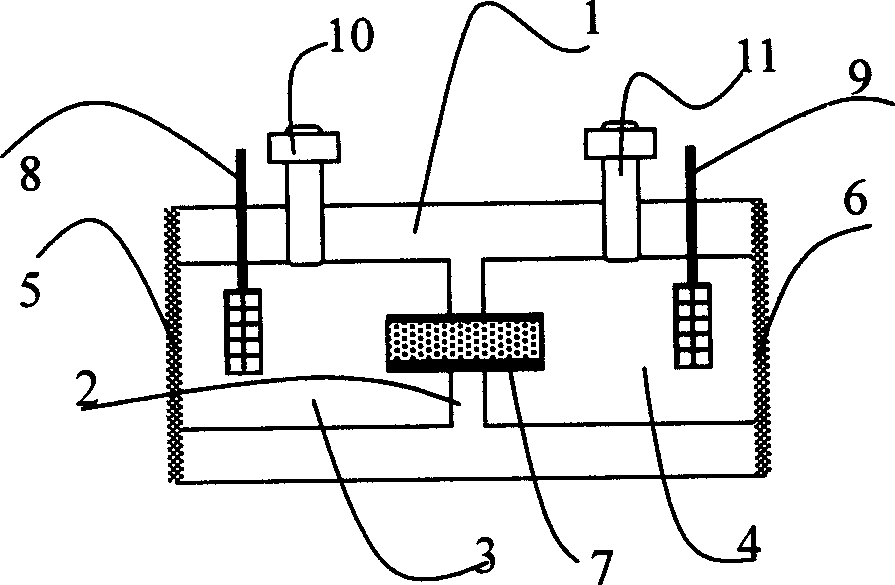

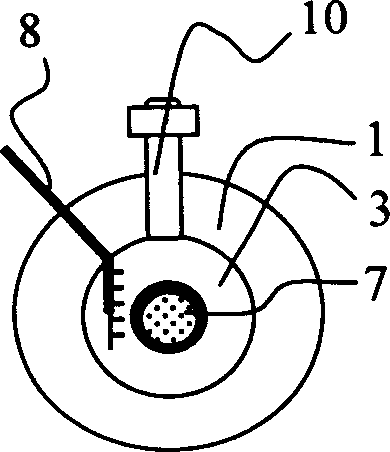

[0032] Embodiment 1: Diaphragm drum in the electroosmosis drum of the present invention

[0033] In the middle part of a drum body 1 made of plexiglass, a plexiglass drum partition 2 divides the tympanic cavity laterally into a front tympanic cavity 3 and a rear tympanic cavity 4, and a silicon rubber film is respectively covered at the openings of the tympanic cavity 3 and 4. Tympanic membranes 5 and 6, a glass sand core electroosmotic column 7 runs through the tympanic septum 2 and is sealed with epoxy resin, and platinum black electrodes 8 and 9 are respectively installed in the tympanic cavity 3 and 4, and their electrode wires are led out to the closed Outside the tympanic cavity; the corresponding drum bodies of the tympanic cavity 3 and 4 are respectively equipped with stainless steel valves 10 and 11, through which the tympanic cavity 3 and 4 are respectively injected and filled with a concentration of 0-1.0mmol / l diethanolamine or After the electroosmotic solution of ...

Embodiment 2

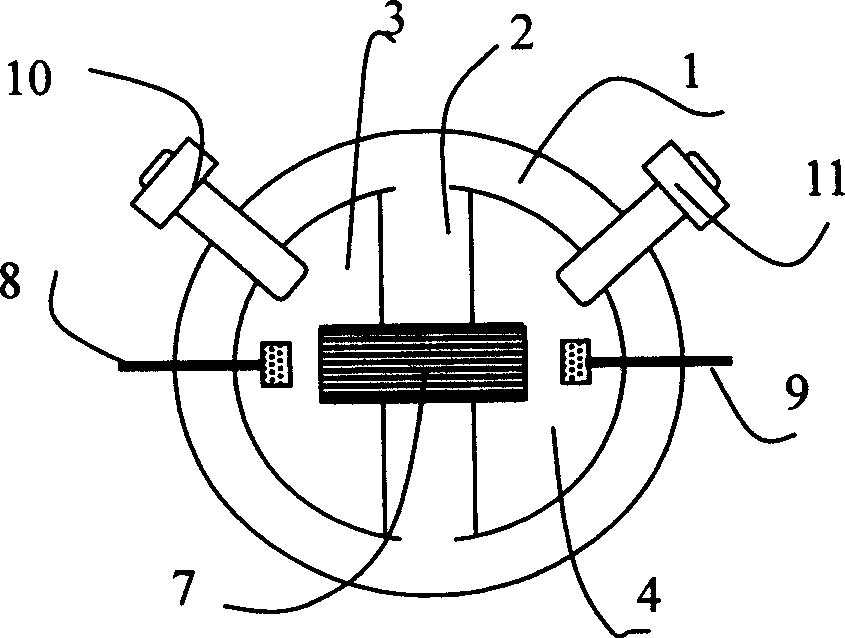

[0036] Example 2: Mediastinal drum in the electroosmotic drum of the present invention

[0037] In a drum body 1 made of polytetrafluoroethylene, there is a longitudinal septum 2 that separates the drum cavity into a left sub-tympanic cavity 3 and a right sub-tympanic cavity 4, and the two ends of the drum cavity 3 and 4 are respectively covered with Elastic membrane tympanic membranes 5 and 6 of electrically insulating material, a quartz capillary electroosmosis column 7 runs through the tympanic septum 2 and is sealed with epoxy resin, platinum mesh electrodes 8 and 9 are respectively set in the tympanic cavity 3 and 4, and the left and right drums The body is provided with valves 10 and 11 respectively, through the valves 10 and 11, the tympanic cavity 3 and 4 are filled with ammonia water with a concentration of 0-1.0mmol / l as the electroosmotic fluid, and the valves 10 and 11 are closed, that is, as attached image 3 (top perspective view) and attached Figure 4 (Side pe...

Embodiment 3

[0039] Example 3: Diaphragmatic electroosmotic drums connected in series

[0040] More than two transverse electroosmotic drums 12 are arranged head to tail in the same direction and fixed on the base 13, the tympanic membrane of the former electroosmotic drum is bonded with the tympanic membrane of the latter electroosmotic drum through the connecting block 14, as attached Figure 5 As shown, it is a series diaphragm drum.

[0041] When in use, apply an alternating voltage or current with a certain period and phase on the two electrodes of each electroosmotic drum, and keep the electrolytic electric quantity integrals in the two directions of each cycle equal. Vibration output with superimposed waveform and intensity is obtained on the drums at both ends. In a typical situation, if an alternating voltage or current with the same amplitude and phase is applied to the two electrodes of each electroosmotic drum, the output with the same waveform and energy addition can be obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com