Preparation material of slow-release fertilizer coating agent based on alkenyl succinic anhydride

A technology of alkenyl succinic anhydride and slow-release fertilizers, applied in fertilizer mixtures, layered/coated fertilizers, fertilization devices, etc., can solve the problems of complex production process, high reaction temperature, slow coating speed, etc., and achieve the transportation process Convenience, good reactivity, good toughness and binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

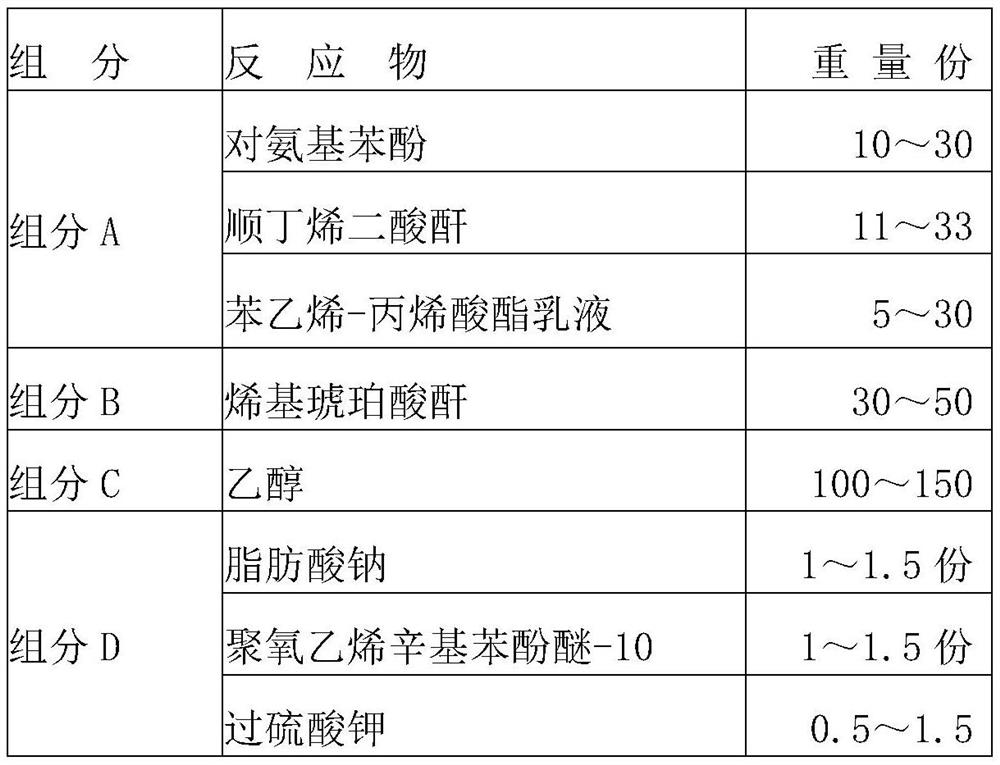

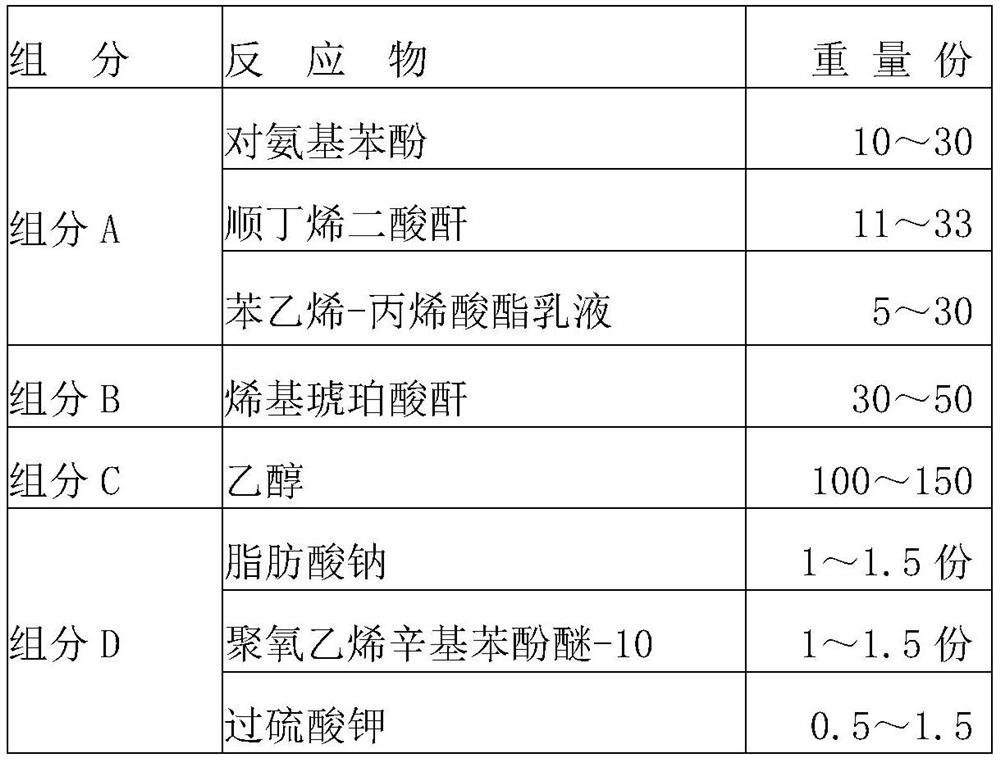

Embodiment 1

[0024] Disperse 30kg of p-aminophenol, 33kg of maleic anhydride, and 30kg of styrene-acrylic acid ester emulsion evenly in 150kg of ethanol, use ammonia water to adjust PH=7, add 0.5kg of potassium persulfate, 1kg of sodium fatty acid and 1,5kg Polyoxyethylene octylphenol ether-10 was stirred at a speed of 3000r / min for 1min with a high-speed shear dispersing emulsifier to obtain a solid particle suspension; The emulsifier was stirred at 2000r / min for 5 minutes to prepare a certain mass fraction of alkenyl succinic anhydride (ASA) slow-release fertilizer coating solution.

[0025] Soak the fertilizer granules in the coating solution for 10 minutes, then take them out, and dry them at 60°C for 4 hours to obtain the coated fertilizer.

Embodiment 2

[0027] Disperse 15kg of styrene-acrylate emulsion, 10kg of p-aminophenol and 11kg of maleic anhydride in 100kg of ethanol, adjust the pH to 7.5 with ammonia water and add 1kg of potassium persulfate, 1kg of sodium fatty acid and 1.5kg of poly Oxyethylene octylphenol ether-10, stirred at 2000r / min for 1min with a high-speed shear dispersing emulsifier to obtain a solid particle suspension; then add 40kg of alkenyl succinic anhydride (ASA), and emulsify with high-speed shear at room temperature The machine was stirred at 1500r / min for 8 minutes to prepare a certain mass fraction of alkenyl succinic anhydride (ASA) slow-release fertilizer coating solution.

[0028] Soak the fertilizer granules in the coating solution for 10 minutes, then take them out, and dry them at 60°C for 4 hours to obtain the coated fertilizer.

Embodiment 3

[0030] Disperse 10kg of p-aminophenol and 33kg of maleic anhydride evenly in 120kg of ethanol, adjust the pH to 6.5 with ammonia water, then add 1.5kg of potassium persulfate, 1kg of sodium fatty acid and 1kg of polyoxyethylene octylphenol ether- 10. Stir at 3000r / min with a high-speed shear emulsifier for 1min to obtain a suspension of solid particles, then add 50kg of alkenyl succinic anhydride (ASA), and use a high-speed shear emulsifier at room temperature at 1000r / min Stir for 2 minutes to prepare a certain mass fraction of alkenyl succinic anhydride (ASA) slow-release fertilizer coating solution.

[0031] Soak the fertilizer granules in the coating solution for 10 minutes, then take them out, and dry them at 60°C for 4 hours to obtain the coated fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com