Preparation method of slow-release fertilizer coating liquid using alkyl ketene dimers

A technology using alkyl ketene dimers and slow-release fertilizers, which is applied in the direction of solid/semi-solid fertilizers, fertilizer mixtures, layered/coated fertilizers, etc., and can solve complex production processes, long coating time, and reaction temperature Advanced problems, to achieve the effect of simple coating process, not easy to release the film, and good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

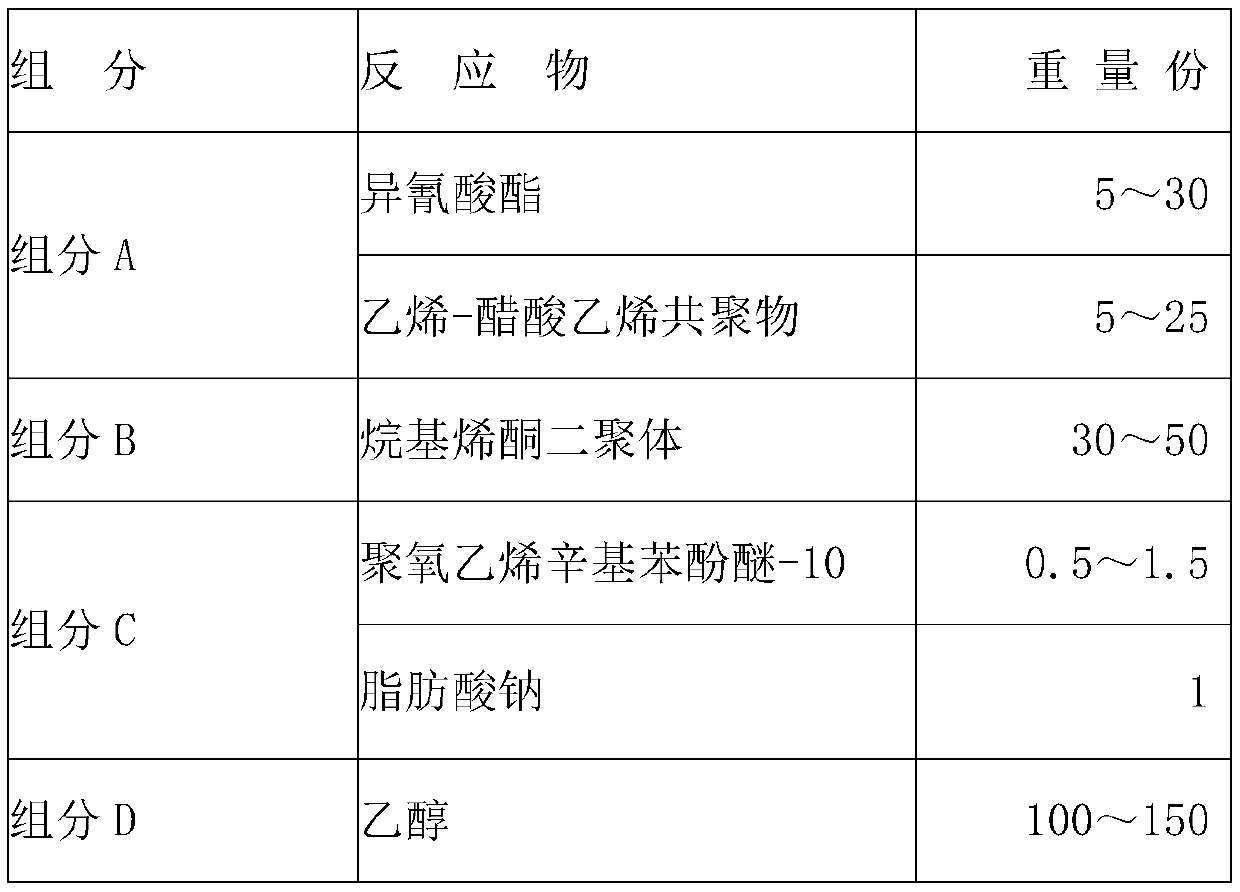

Embodiment 1

[0029] Evenly disperse 30kg of isocyanate and 15kg of ethylene-vinyl acetate copolymer in 150kg of ethanol, adjust the pH to 7 with ammonia water, add 1kg of sodium fatty acid, 0.5kg of polyoxyethylene octylphenol ether-10 and 10kg of alkylketene Dimer (AKD), stir 1min under 3000r / min rotating speed with high-speed shear dispersing emulsifier, make microparticle suspension, add the alkyl ketene dimer (AKD) of 20kg again, use high-speed shear under room temperature The emulsifier was stirred at 1000r / min for 5 minutes to obtain the alkyl ketene dimer (AKD) slow-release fertilizer coating solution.

[0030] Put the granular fertilizer into the fluidized bed coating machine, spray the coating agent on the rolling fertilizer particles, and ventilate and dry at the same time, until a uniform separation film is formed outside the particles, the coated fertilizer is obtained.

Embodiment 2

[0032] Disperse 25kg of ethylene-vinyl acetate copolymer evenly in 100kg of ethanol, adjust PH=6 with ammonia water, add 1kg of sodium fatty acid, 1.5kg of polyoxyethylene octylphenol ether-10 and 10kg of alkyl ketene dimer (AKD), stir 1min under the rotating speed of 3000r / min with a high-speed shearing emulsifier to obtain a microparticle suspension, then add 30kg of alkyl ketene dimer (AKD), and use a high-speed shearing emulsifier at room temperature Stir at 2000r / min for 20min to obtain an alkyl ketene dimer (AKD) slow-release fertilizer coating solution.

[0033] Put the granular fertilizer into the fluidized bed coating machine, spray the coating agent on the rolling fertilizer particles, and ventilate and dry at the same time, until a uniform separation film is formed outside the particles, the coated fertilizer is obtained.

Embodiment 3

[0035] 15kg of isocyanate is uniformly dispersed in 130kg of ethanol, and after using ammonia water to adjust PH=6.5, add 1kg of sodium fatty acid, 0.5kg of polyoxyethylene octylphenol ether-5 and 10kg of alkyl ketene dimer (AKD), and use A high-speed shearing emulsifier was stirred at a speed of 3000r / min for 2min to obtain a suspension of solid particles, and then 40kg of alkyl ketene dimer (AKD) was added, and the high-speed shearing emulsifier was used at room temperature at a speed of 1000r / min. Stir at low temperature for 20 minutes to obtain the coating liquid of alkyl ketene dimer (AKD) slow-release fertilizer.

[0036] Put the granular fertilizer into the fluidized bed coating machine, spray the coating agent on the rolling fertilizer particles, and ventilate and dry at the same time, until a uniform separation film is formed outside the particles, the coated fertilizer is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com