Hot-line work vehicle

A technology for live work and vehicles, used in overhead lines/cable equipment, hoisting devices, etc., can solve problems such as poor passability, achieve the effect of stable support, avoid shaking, and ensure operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

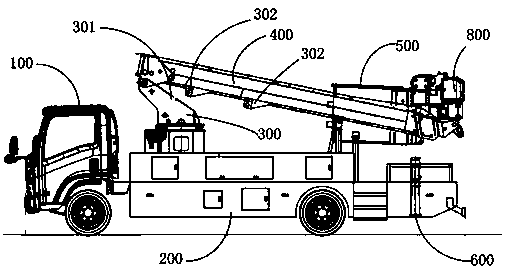

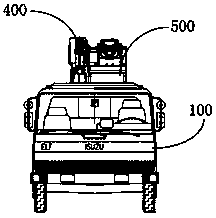

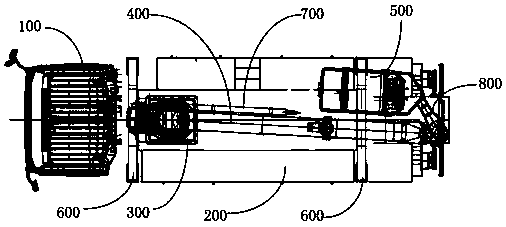

[0030] see Figure 1 to Figure 4 , this embodiment provides a live working vehicle, including:

[0031] The vehicle body includes a cab 100 and a carrying platform 200, the cab 100 and the carrying platform 200 are sequentially installed on the frame of the vehicle from the front to the rear of the vehicle, wherein the carrying platform A bearing space is formed above 200, the height of the bearing platform 200 matches the height of the vehicle frame, and the height of the vehicle frame is consistent with the height of the wheels of the vehicle;

[0032] The turntable 300 is installed on the carrying platform 200 and arranged adjacent to the cab 100, the turntable 300 can rotate relative to the carrying platform 200;

[0033] A cantilever 400 has two opposite ends, one end of the cantilever 400 is connected to the turntable 300, so that the other end of the cantilever 400 can be raised and lowered relative to the carrying platform 200; and

[0034] The working bucket 500 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com