Device for researching mechanical property of anchor rod under action of impact force as well as use method of device

A technology of bolt mechanics and impact force, applied in the field of geotechnical mechanics, can solve problems such as deep rock mass disasters and failure of bolt support in high-stress engineering surrounding rock, achieving simple operation, saving test costs, and intuitive and real tests. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

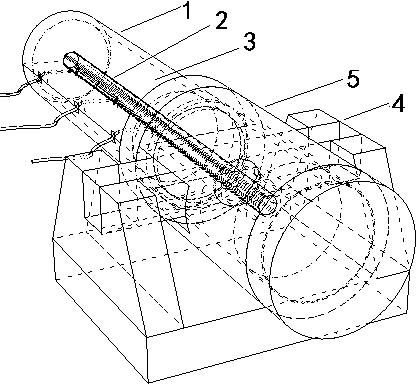

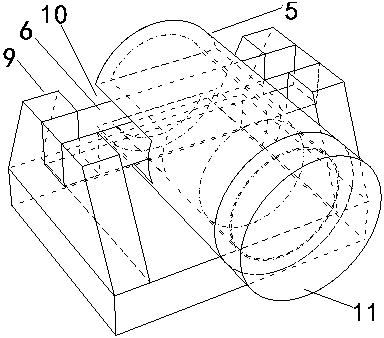

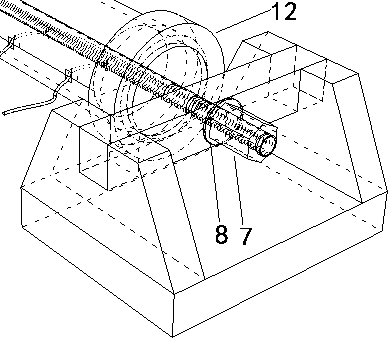

[0037] as attached Figure 1-4 As shown, the research device for the mechanical properties of the anchor rod under the action of impact force includes a casing, an anchor rod, an anchoring agent, a fixed end and an impacted end. The anchoring agent anchors the anchor rod in the casing, and one end of the anchor rod is outside the casing. The end is fixedly connected to the ground through the fixed end, and the impacted end passes through the fixed end and contacts the casing.

[0038] The fixed end includes a fixed block, a nut, a gasket and a fixed seat. The fixed block is long and has a hole in the middle, and the anchor rod passes through the hole. The nut matches the thread of the anchor rod, and the nut and the gasket are installed on the anchor On the rod, the position of the fixed block is limited, the two ends of the fixed block are located outside the impacted end, the two ends of the fixed block are fixedly connected with the fixed seat, and the fixed seat is fixedly...

Embodiment 2

[0054] The difference between this embodiment and embodiment 1 is: 1. the structure of the impact protection sleeve is different, as attached Figure 6 As shown, one end of the impact protection sleeve in this embodiment is a smaller cylinder, which is inserted into the casing, and the other end is a larger cylinder, which accepts the insertion of the impacted end; 2. The structure of the impacted block is different , in this implementation, the end with a larger outer diameter of the impacted block is a cylinder, which accepts the insertion of the incident rod. In this embodiment, the impact protection and the impacted block are coaxially and stably connected with the bushing, the impact end, and the incident rod, which is beneficial to the transmission of impact force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com