Polarizer, color film substrate, display panel and display device

A color film substrate and display panel technology, which is applied in the direction of polarizing elements, optics, instruments, etc., can solve the problems of penetrating into the panel, silver glue oxidation, and reducing the display effect of the product, so as to improve product quality and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

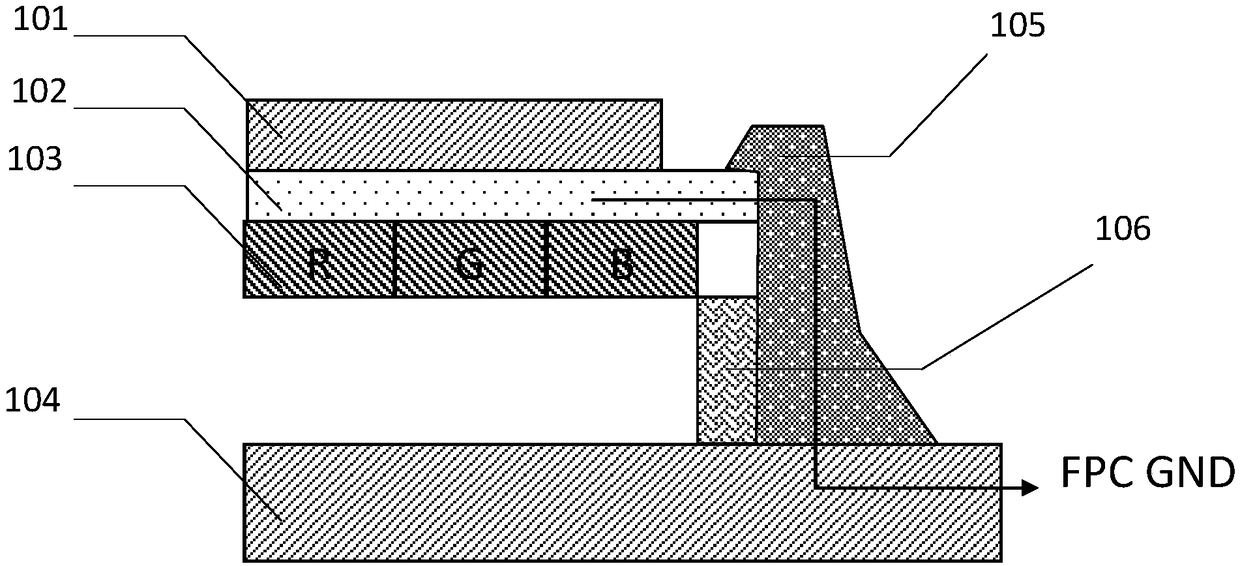

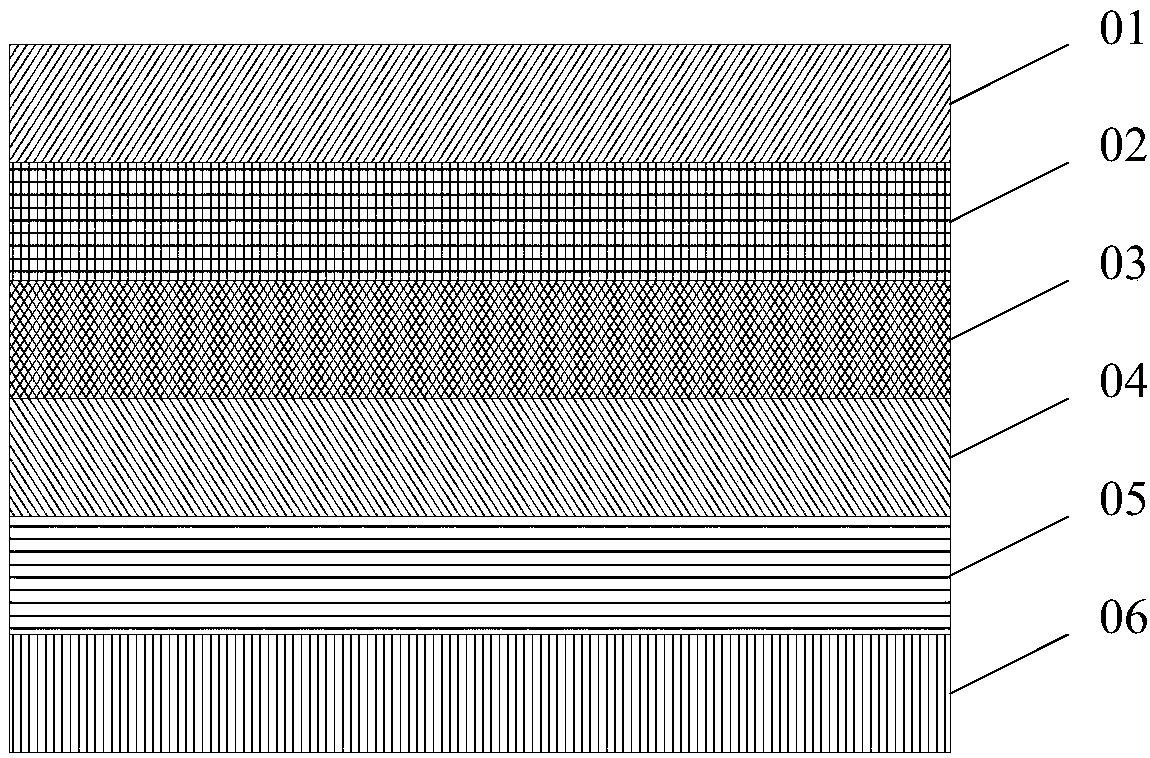

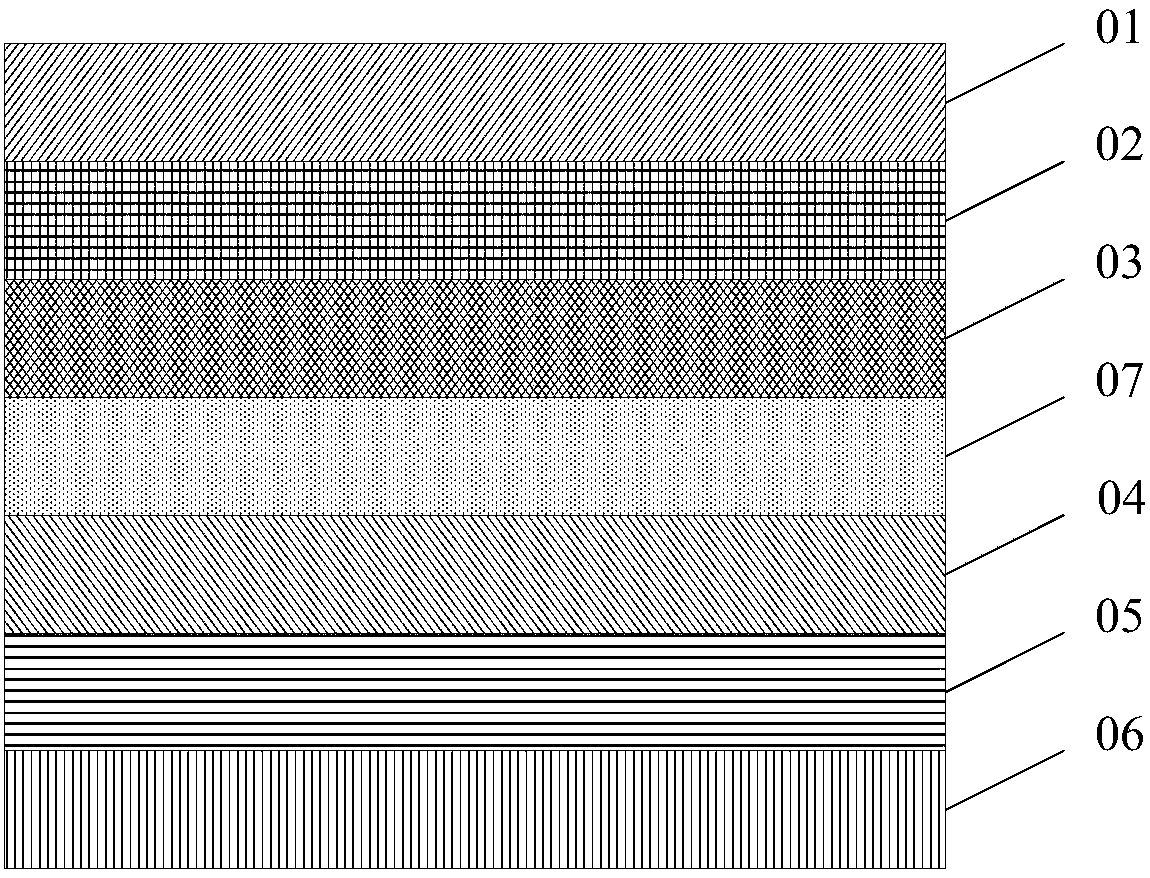

[0034] Embodiments of the present application provide a polarizer, a color filter substrate, a display panel, and a display device, which are used to conduct away static electricity on the color filter substrate through the polarizer, so that the conductive layer disposed on the color filter substrate can be omitted. The process of removing ITO that needs to be carried out when attaching Touch products later is omitted, and the product quality can also be improved at the same time.

[0035] In the embodiment of the present application, by adding one or more transparent conductive film layers to the polarizer, such as adding one or more graphene layers (of course, other transparent conductive materials can also be used), or adding graphene to the existing There is any layer structure in the polarizer, thereby replacing Back ITO. Since Back ITO is omitted, it also saves the process of removing Back ITO that needs to be carried out when attaching Touch products later, and can also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com