Automobile oil cooler

A technology for oil coolers and automobiles, used in engine components, engine lubrication, lubricating parts, etc., can solve the problems of high production cost, complex structure, limited contact area of oil cooler tubes, etc., and slow down the oil flow speed. , good oil cooling effect, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

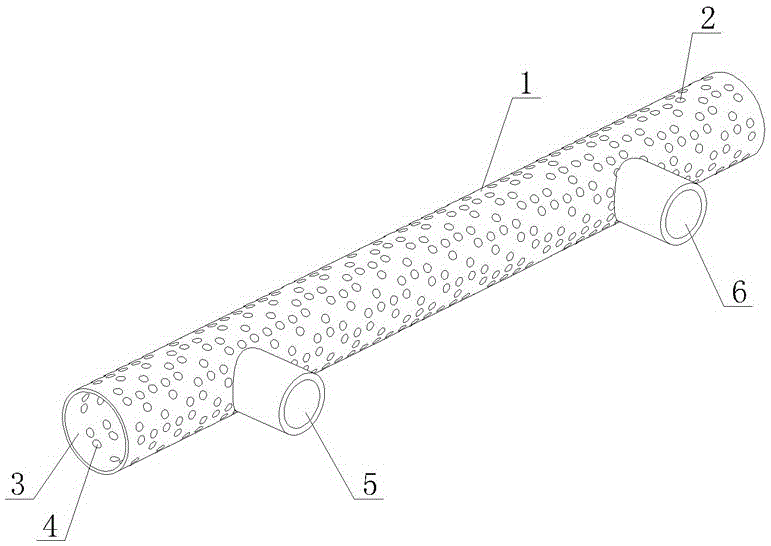

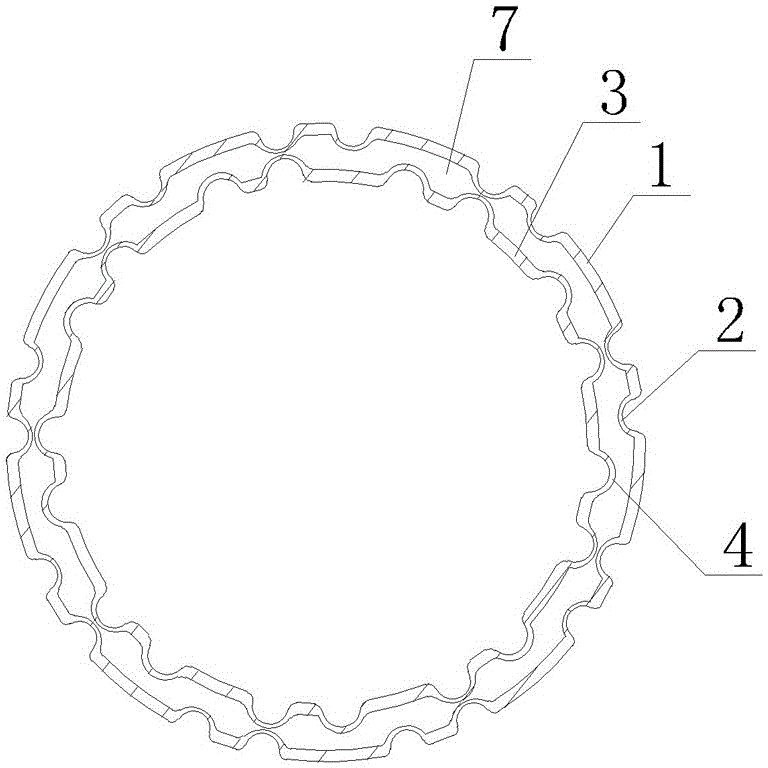

[0012] As shown in the figure, the automotive oil cooler of the present invention includes an oil cooler tube body, the oil cooler tube body has a double-layer tube wall with an inner tube wall 3 and an outer tube wall 1, and the tubes with inner and outer double-layer tube walls The end is sealed and closed, and the middle of the inner and outer double-layer pipe walls surrounds an oil passage cavity 7. One end of the outer pipe wall 1 is provided with an oil inlet 5 and the other end is provided with an oil outlet 6, and the oil inlet and outlet are connected to the oil passage. Cavity 7, the outer tube wall 1 is densely covered with irregularly distributed first concave points 2, the first concave points 2 are formed on the outer tube wall 1 by rolling, and the inner tube wall 3 is densely covered with irregular Distributed second concave points 4, the second concave points 4 are formed on the inner tube wall 3 by rolling, the first and second concave points are aligned with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com