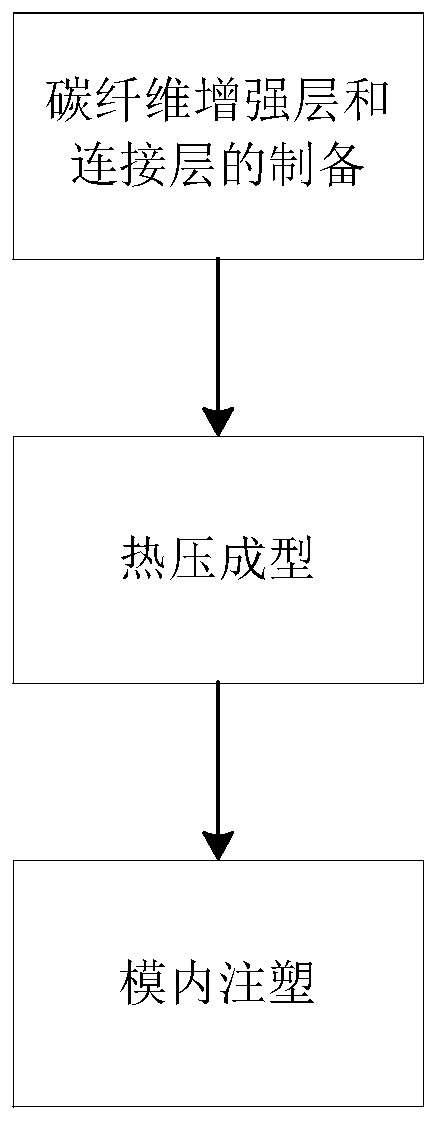

A preparation method and product of a carbon fiber-reinforced multilayer structure injection molding product

A multi-layer structure, injection molding product technology, applied in the direction of coating, can solve the problems of affecting the mechanical properties of products, easy to meet the requirements, and high processing costs, to reduce the appearance defect rate, enhance appearance protection, and simplify the production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

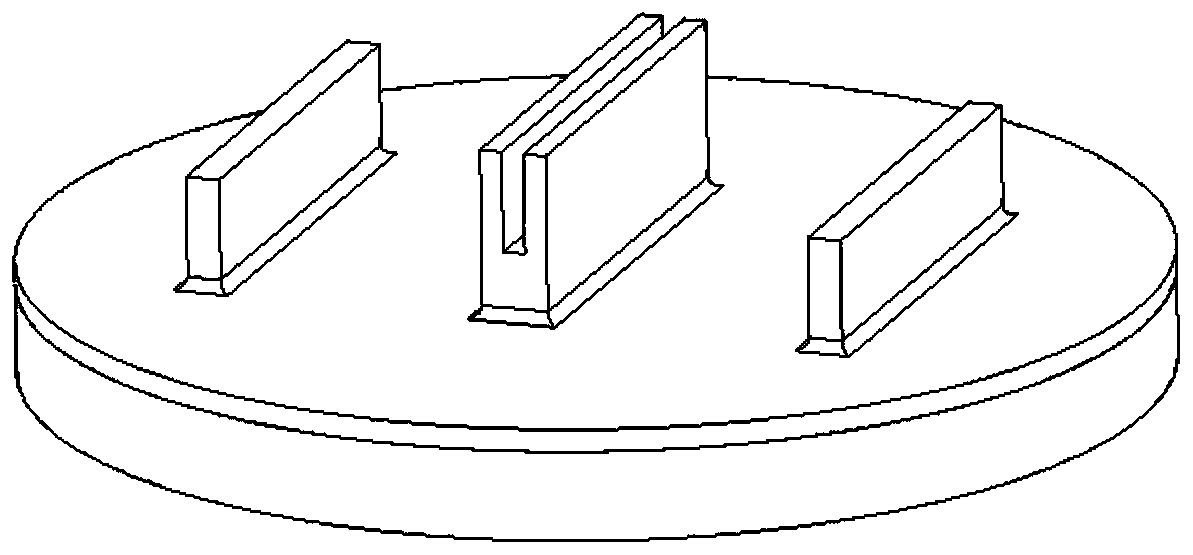

[0042] Preparation of prepreg: Coat a layer of polycarbonate powder on the surface of carbon fiber cloth by electrostatic powder spraying method, bake in an oven at 230°C for 10 minutes, and prepare a carbon fiber reinforced layer sheet with a plastic content of 35%; polycarbonate and Polypropylene was mixed at a ratio of 3:2, 5% (wt) PP-g-MAH was added, powder was coated on carbon fiber cloth by powder spraying, and the middle layer sheet was obtained by baking in an oven at 200°C for 10mim.

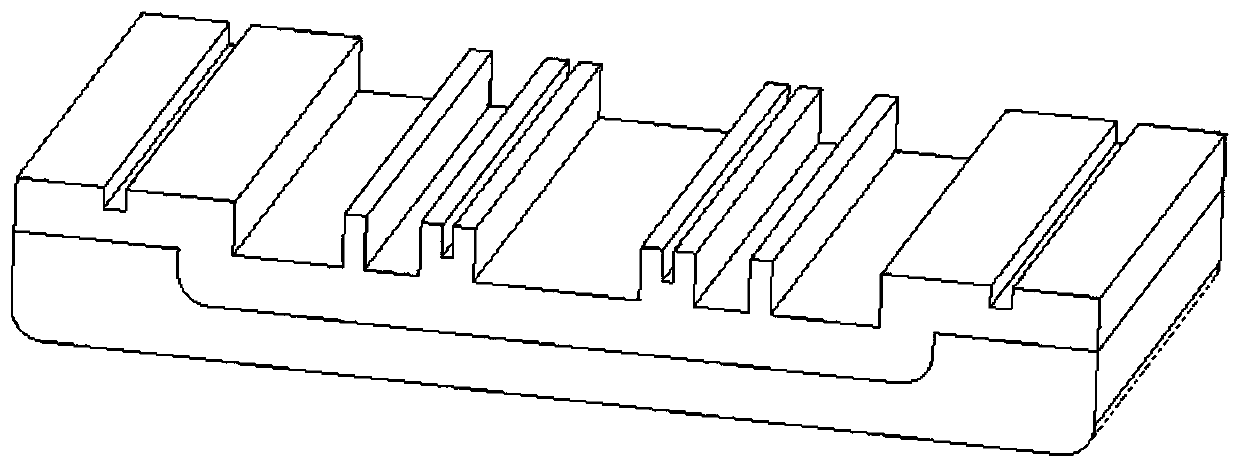

[0043] Hot press forming: the mold temperature is increased to 180°C, ten layers of prepreg are put into the hot press mold in sequence, the top layer is the connecting layer, the inside of the hot press is vacuumed to below 1KPa, and the mold temperature is raised to 240°C, Clamp the mold with a hot press, apply a pressure of 5 tons and keep warm for 30 minutes to obtain a composite material product.

[0044]Cooling and cleaning: Stop heating and vacuuming, cool to 100°C at a cooling r...

Embodiment 2

[0047] Preparation of prepreg: Coat a layer of polycarbonate powder on the surface of carbon fiber cloth by electrostatic powder spraying, bake in an oven at 260°C for 5 minutes, and prepare a carbon fiber reinforced layer sheet with a plastic content of 70%; polycarbonate and Polypropylene was mixed at a ratio of 4:1, 20% (wt) of PP-g-MAH was added, powder was coated on carbon fiber cloth by powder spraying, and the middle layer sheet was obtained by baking in an oven at 250°C for 5mim.

[0048] Hot press forming: the mold temperature is increased to 180°C, ten layers of prepreg are put into the hot press mold in sequence, the top layer is the connection layer, the inside of the hot press is vacuumed to below 1KPa, and the mold temperature is raised to 260°C, Clamp the mold with a hot press, apply a pressure of 10 tons and keep warm for 15 minutes to obtain a composite material product.

[0049] Cooling and cleaning: Stop heating and vacuuming, cool to 100°C at a cooling rate...

Embodiment 3

[0052] Preparation of prepreg: Coat a layer of polycarbonate powder on the surface of carbon fiber cloth by electrostatic powder spraying method, bake in an oven at 240°C for 8 minutes, and prepare a carbon fiber reinforced layer sheet with a plastic content of 45%; polycarbonate and Polypropylene is mixed in a ratio of 7:3, 10% (wt) PP-g-MAH is added, powder is coated on carbon fiber cloth by powder spraying, and the middle layer sheet is obtained by baking in an oven at 220°C for 6mim.

[0053] Hot press forming: the mold temperature is increased to 180°C, ten layers of prepreg are put into the hot press mold in sequence, the top layer is the connection layer, the inside of the hot press is vacuumed to below 1KPa, and the mold temperature is raised to 250°C, Clamp the mold with a hot press, apply a pressure of 8 tons and keep warm for 20 minutes to obtain a composite material product.

[0054] Cooling and cleaning: Stop heating and vacuuming, cool to 100°C at a cooling rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com