Mortar for reinforced autoclaved aerated concrete blocks

A technology of concrete blocks and autoclaved air filling, which is applied in the field of building materials, can solve the problems of general screening results, affecting the quality of mortar, and monotonous color, etc., and achieve the effect of improving quality and purity, improving mortar quality, and improving screening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

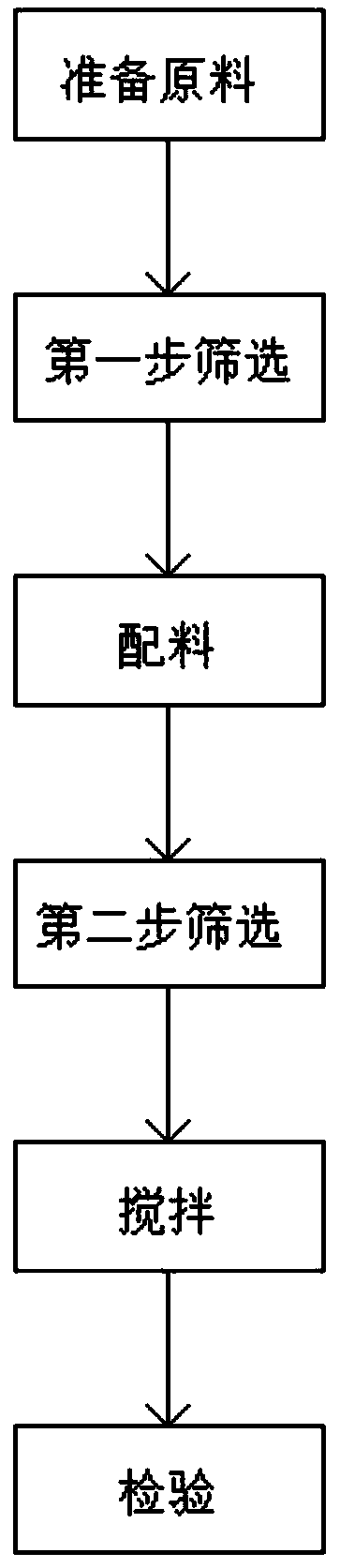

[0019] refer to figure 1 , a reinforced autoclaved aerated concrete block mortar, comprising the following steps:

[0020] S1. Prepare raw materials: the mortar for the reinforced autoclaved aerated concrete block is composed of sand, cement, water, admixtures and external additives. Prepare various raw materials required for mortar processing. The sand aggregate is mainly Quartz sand, river sand, crushed limestone, etc. must be inspected for impurity content and particle size distribution before use. Sand containing impurities must be washed and dried, and its final humidity must be less than 0.5%. Dried and dried river sand coarse sand (d>1.0mm) has better fluidit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap