A kind of high-strength cold heading steel wire rod and its production method

A cold heading steel, high-strength technology, applied in the direction of metal rolling, etc., can solve the problem that the internal performance uniformity and fatigue performance of finished fasteners cannot be improved, and achieve excellent cold heading performance, internal Composition and tissue homogeneity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

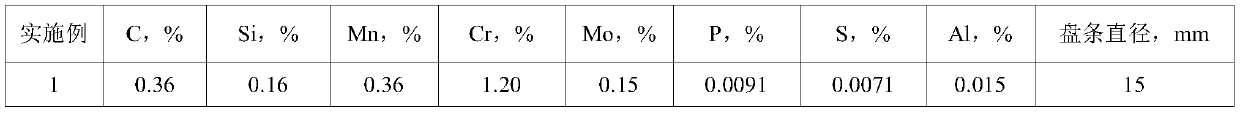

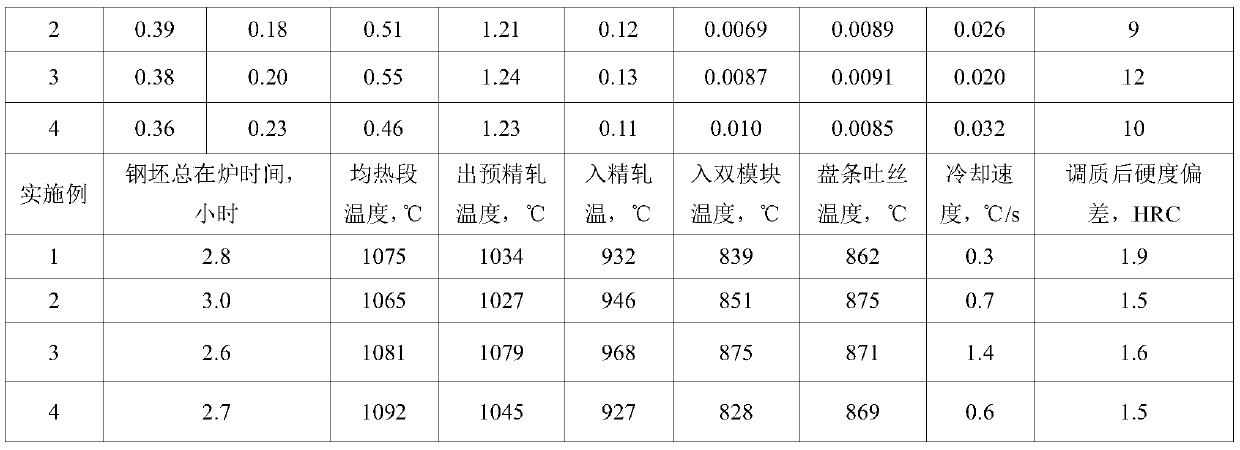

[0032] The following table includes 4 examples

[0033]

[0034]

Embodiment 1

[0036] A high-strength cold heading steel wire rod, the chemical composition ratio is: [C] 0.36%, [Si] 0.16%, [Mn] 0.36%, [P] 0.0091%, [S] 0.0071%, [Cr] 1.20% , [Mo] 0.15%, [Al] 0.015%. Wire rod diameter: 15mm.

[0037] The production process parameters of the above-mentioned high-strength cold heading steel wire rod are controlled as follows: the total billet time in the furnace: 2.8 hours, the temperature control of the soaking section: 1075 ° C, the temperature control of the pre-finishing rolling: 1034 ° C, the temperature control of the finishing rolling It is: 932°C, the temperature control of entering the double module is: 839°C, the temperature control of wire rod spinning is: 862°C, and the cooling speed control is: 0.3°C / s.

[0038] Results: The hardness deviation of a high-strength cold heading steel wire rod after quenching and tempering using the above-mentioned production process and chemical composition is 1.9HRC.

Embodiment 2

[0040] A high-strength cold heading steel wire rod, the chemical composition ratio is: [C] 0.39%, [Si] 0.18%, [Mn] 0.51%, [P] 0.0069%, [S] 0.0089%, [Cr] 1.21% , [Mo] 0.12%, [Al] 0.026%. Wire rod diameter: 9mm.

[0041] The production process parameters of the above-mentioned high-strength cold heading steel wire rod are controlled as follows: the total billet time in the furnace: 3.0 hours, the temperature control of the soaking section: 1065 °C, the temperature control of the pre-finishing rolling: 1027 °C, the temperature control of the finishing rolling It is: 946 °C, the temperature control of entering the double module is: 851 °C, the temperature control of wire rod spinning is: 875 °C, and the cooling speed control is: 0.7 °C / s.

[0042] Results: The hardness deviation of a high-strength cold heading steel wire rod after quenching and tempering using the above-mentioned production process and chemical composition is 1.5HRC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap