Apparatus and method for determining the proportion of additives and a machine for the tobacco processing industry

A technology of additives and tobacco, which is applied in the fields of tobacco, application, and cigarette manufacturing, and can solve problems such as lack of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

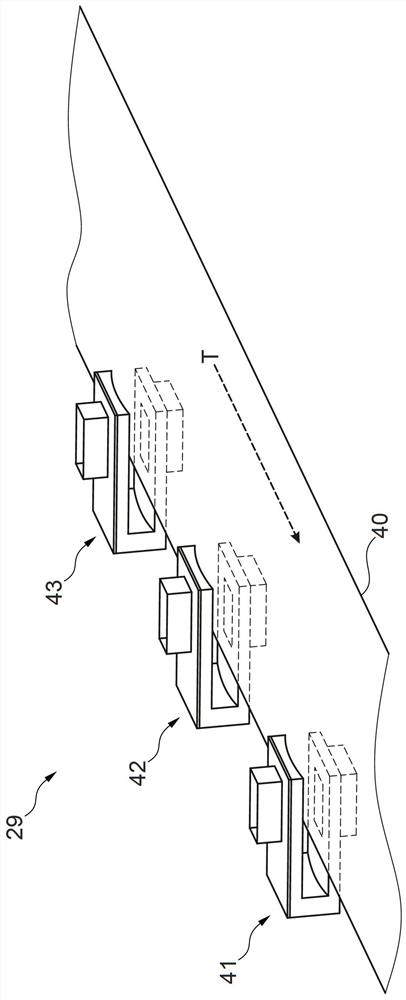

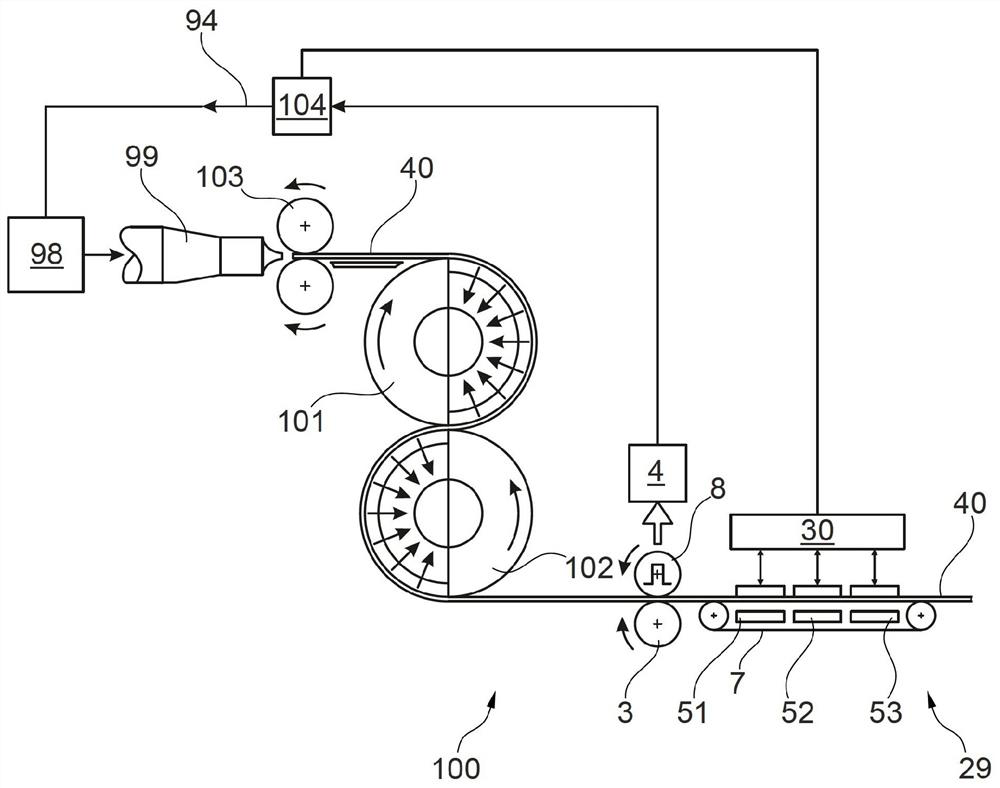

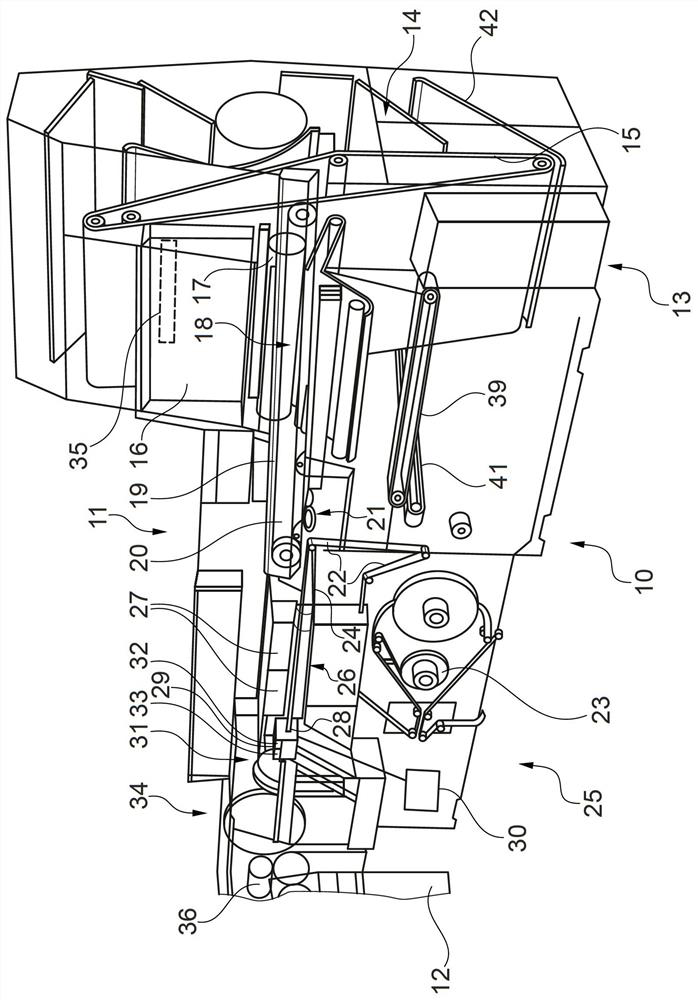

[0029] exist figure 1 The cigarette production machine 10 shown in includes the dispenser / rod unit 11 and the in- figure 1Only the filter tipping machine 12 is shown schematically, the dispenser / rod unit has a dispenser 13 and a rod unit 25 . The dispenser 13 comprises a tobacco reservoir 14, also called a pannier, which is filled with tobacco material from above. Tobacco is extracted from the tobacco storage 14 by means of an inclined conveyor 15 . The distributor 13 also comprises a stagnation shaft 16 from which the tobacco is extracted by means of a separating device 17 and thus separated, and a screening device 18 for sifting the tobacco, in particular for screening out tobacco material veins in the leaf. The sieving device 18 can be designed as desired; in one embodiment not shown it can be, for example, a meander sieve. The stagnation shaft 16 and the separating device 17 can also be arranged in particular downstream of the screening device 18 , ie downstream.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com