High-yield, high-efficiency, light and simple cultivation method for Xinjiang cotton areas

A cultivation method and high-yield technology, applied in the field of high-yield, high-efficiency, light and simple cultivation in Xinjiang cotton region, can solve the problems of low cotton yield, decreased cotton field density, and aggravated pollution hazards of broken leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

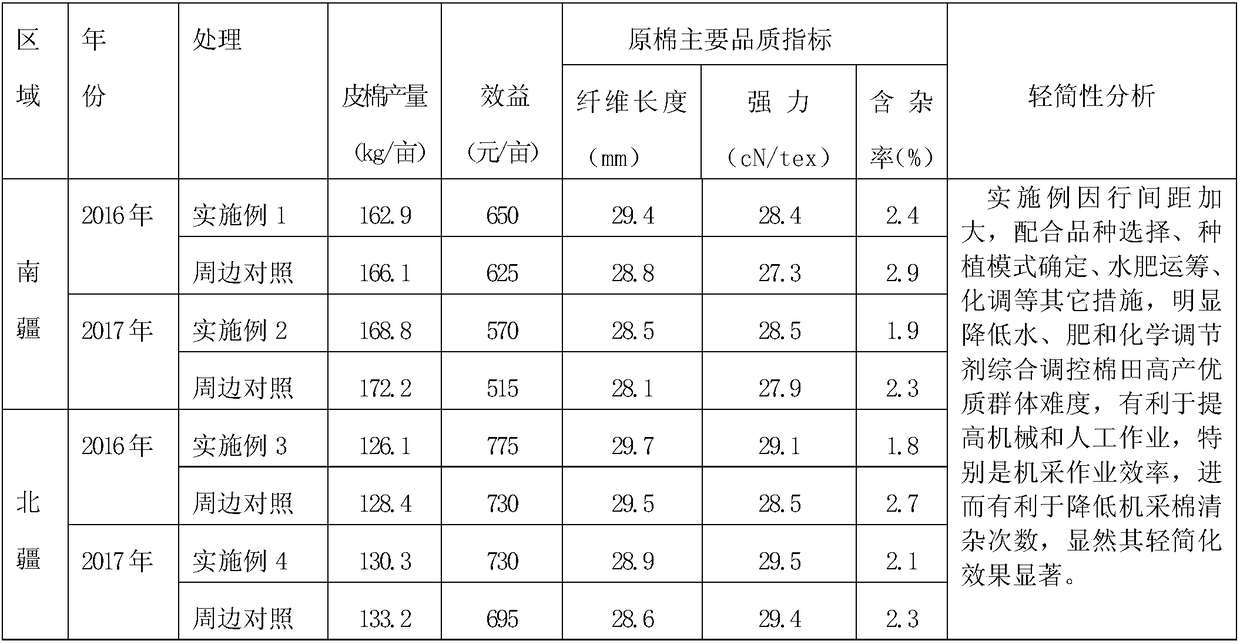

[0030] Example 1 (2016)

[0031] a. Variety selection: Xinluzhong 64 was selected as the variety, the growth period of the year was 134 days, the average length of fruit branch internodes was 8.5cm, it was a type II fruit branch type, the leaf size was medium type, and the stem diameter was 11.8mm at the full boll stage. The leaf inclination angle is 58.1°, and the distance from the boll at the bottom of the cotton plant to the ground is 22.0 cm. Under the conventional high-yield cultivation environment, the rate of double bolls on a single fruiting branch accounts for 35% of the total fruiting branches. The defoliation rate of cotton leaves in the cotton field reached 91.2%, and the opening rate of cotton bolls reached 94.1%;

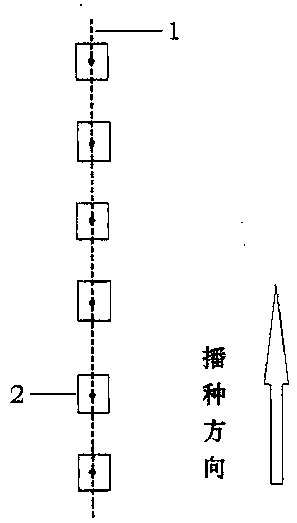

[0032] b. Planting mode: the planting mode of drip irrigation under the film is adopted, and the planting track is a straight line track for each row ( figure 1 ), several seed holes 2 are evenly arranged along the straight line 1, the average row spa...

Embodiment 2

[0048] Example 2 (2017)

[0049] a. Variety selection: Xinluzao 27 was selected as the variety. The growth period of the year was 125 days. The average length of the fruit branch internodes was 5.6cm. The inclination angle is 54.1°, and the distance between the bolls at the bottom of the cotton plant and the ground is 19.6 cm. Under the conventional high-yield cultivation environment, the rate of double bolls per fruiting branch accounts for 28.2% of the total fruiting branches. The cotton leaf defoliation rate is 94.5%, and the cotton boll opening rate is 97.2%;

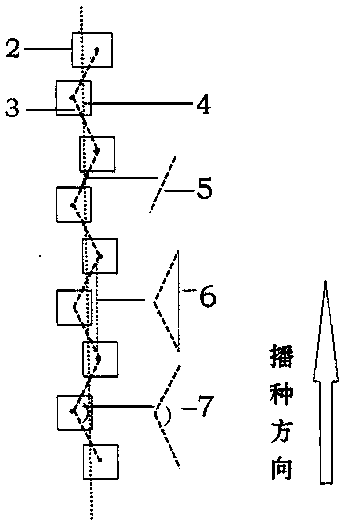

[0050] b. Planting mode: Adopt the equal-row-spacing planting mode of under-film drip irrigation, and the cotton planting behavior is a regular broken-line planting track for each row ( figure 2 ), the regular polyline sowing trajectory is that the seed holes 2 are arranged staggered along the linear middle line 4, and the line segments 5 formed by connecting the center points of any two adjacent seed holes 2 are ...

Embodiment 3

[0069] Example 3 (2016)

[0070] a. Variety selection: Yiluzao 17 was selected as the variety. The growth period of the year was 119 days. The average length of fruit branches between nodes was 5.4cm. The leaf inclination angle is 44.5°, and the distance from the boll at the bottom of the cotton plant to the ground is 18.0 cm. Under the conventional high-yield cultivation environment, the rate of double bolls on a single fruiting branch accounts for 20% of the total fruiting branches. The defoliation rate of cotton leaves in the cotton field reached 93.0%, and the cotton boll opening rate reached 95.4%;

[0071] b. Planting mode: Adopt the equal-row-spacing planting mode of under-film drip irrigation, and the cotton planting behavior is a regular broken-line planting track for each row ( figure 2 ), the regular polyline sowing trajectory is that the seed holes 2 are arranged staggered along the linear middle line 4, and the line segments 5 formed by connecting the center poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com