Steel member spraying device easily fixed on site

A technology for spraying equipment and steel components, applied in the direction of spraying equipment, etc., can solve the problems of low efficiency, high labor intensity of operators, poor processing quality, etc., and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

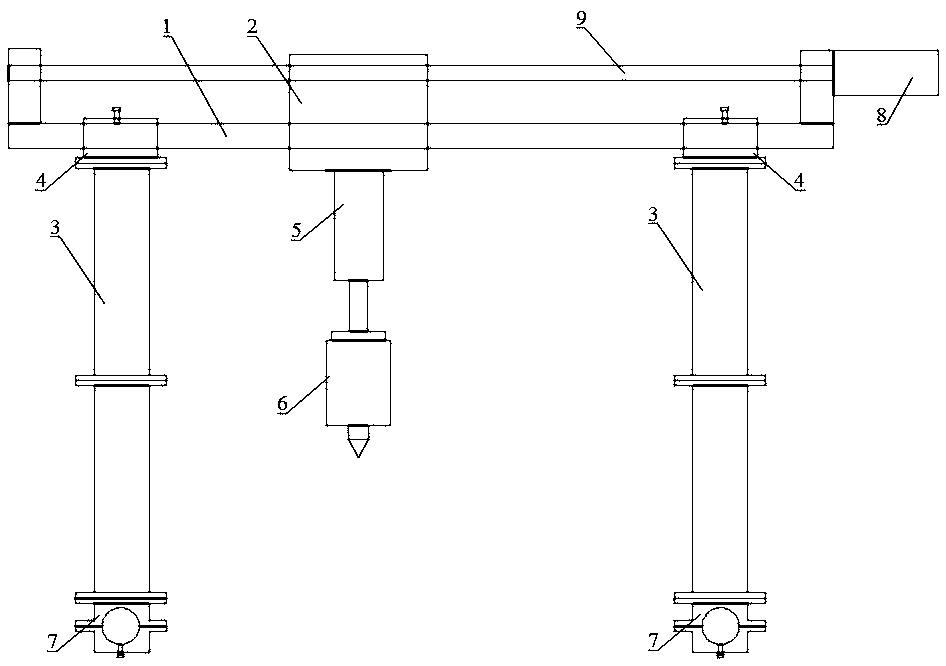

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] like figure 1 As shown, a steel component spraying device that is easy to fix on site includes two columns, a slide rail 1 arranged on the top of the column, a sleeve 2 slidingly installed on the slide rail 1, and a drive sleeve 2 that slides along the slide rail 1 The driving device, the column is composed of a plurality of support units 3, the support unit 3 includes a column body and connecting plates arranged at both ends of the column body, and the plurality of support units 3 forming the same column are connected head to tail in sequence , the connecting plates between the adjacent support units 3 are attached and fixedly connected by bolts, the upper part of the support unit 3 at the top of the column is connected with a slide rail fixing device 4, and the bottom of the slide rail fixing device 4 is connected to the support unit at the top of the column throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com