Clamp for machining rear cover of automobile air conditioning compressor

A technology for automobile air conditioners and compressors, which is applied in the direction of manufacturing tools, metal processing equipment, and metal processing machinery parts, etc. Improve the accuracy of repeat positioning, save clamping time and times, and reduce processing procedures and personnel to solve problems such as compressor quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

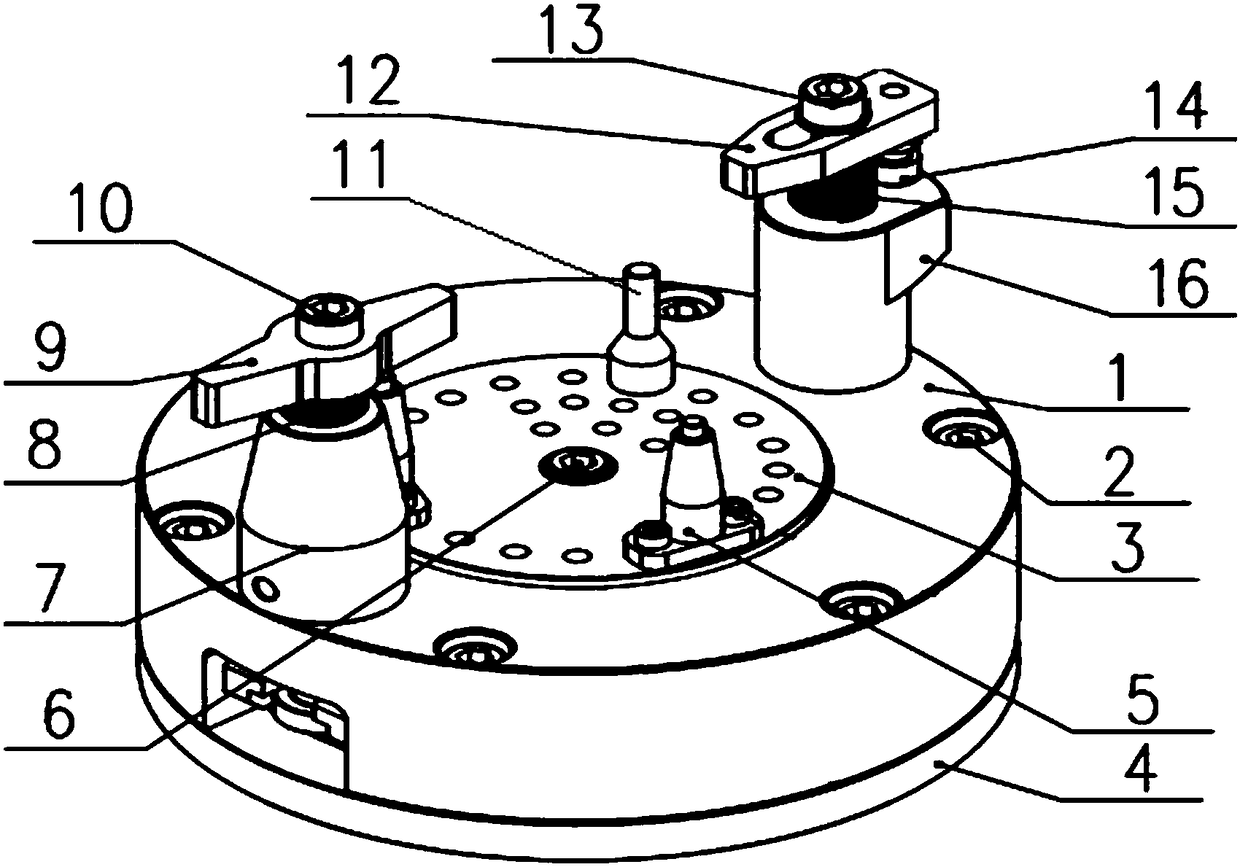

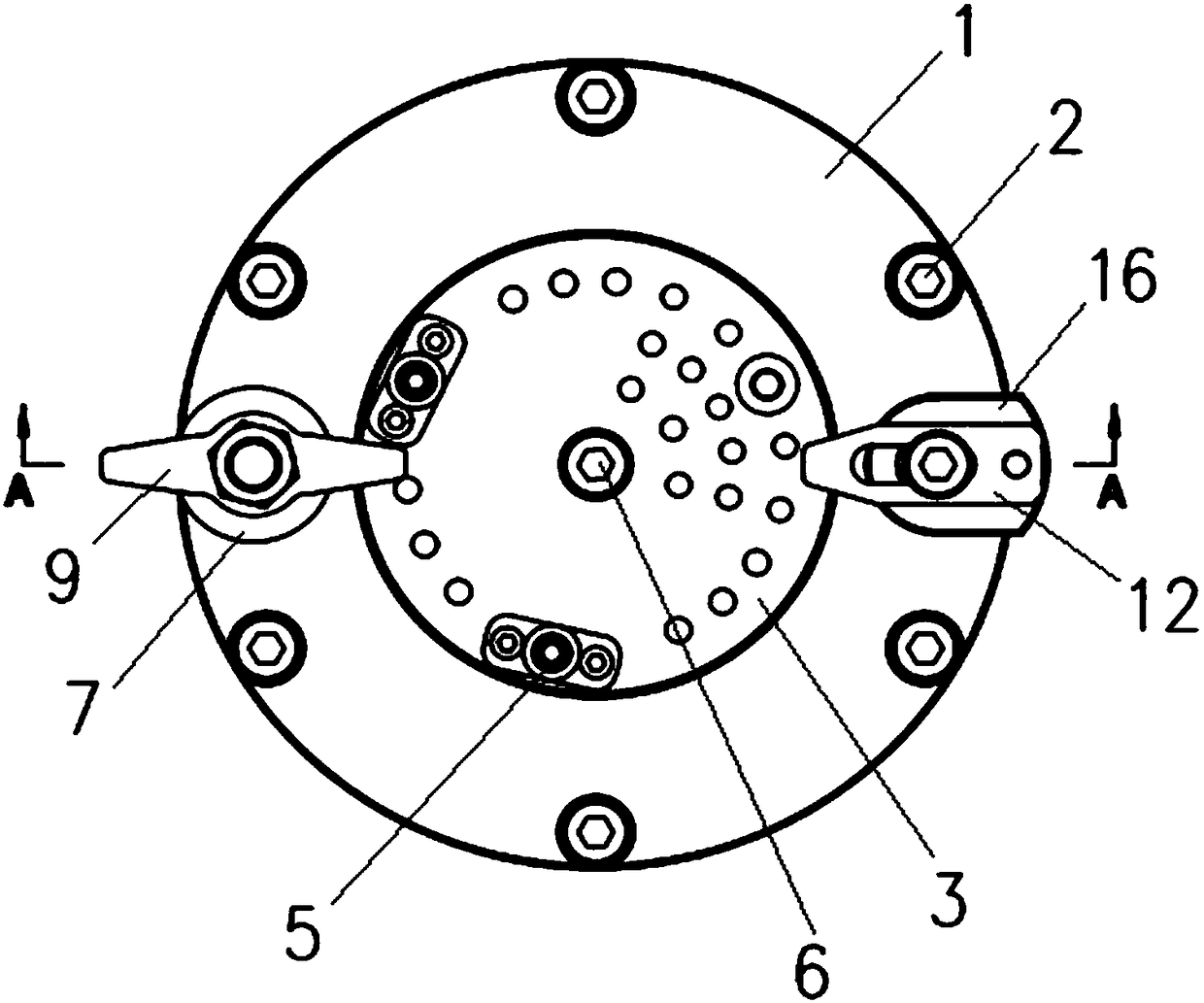

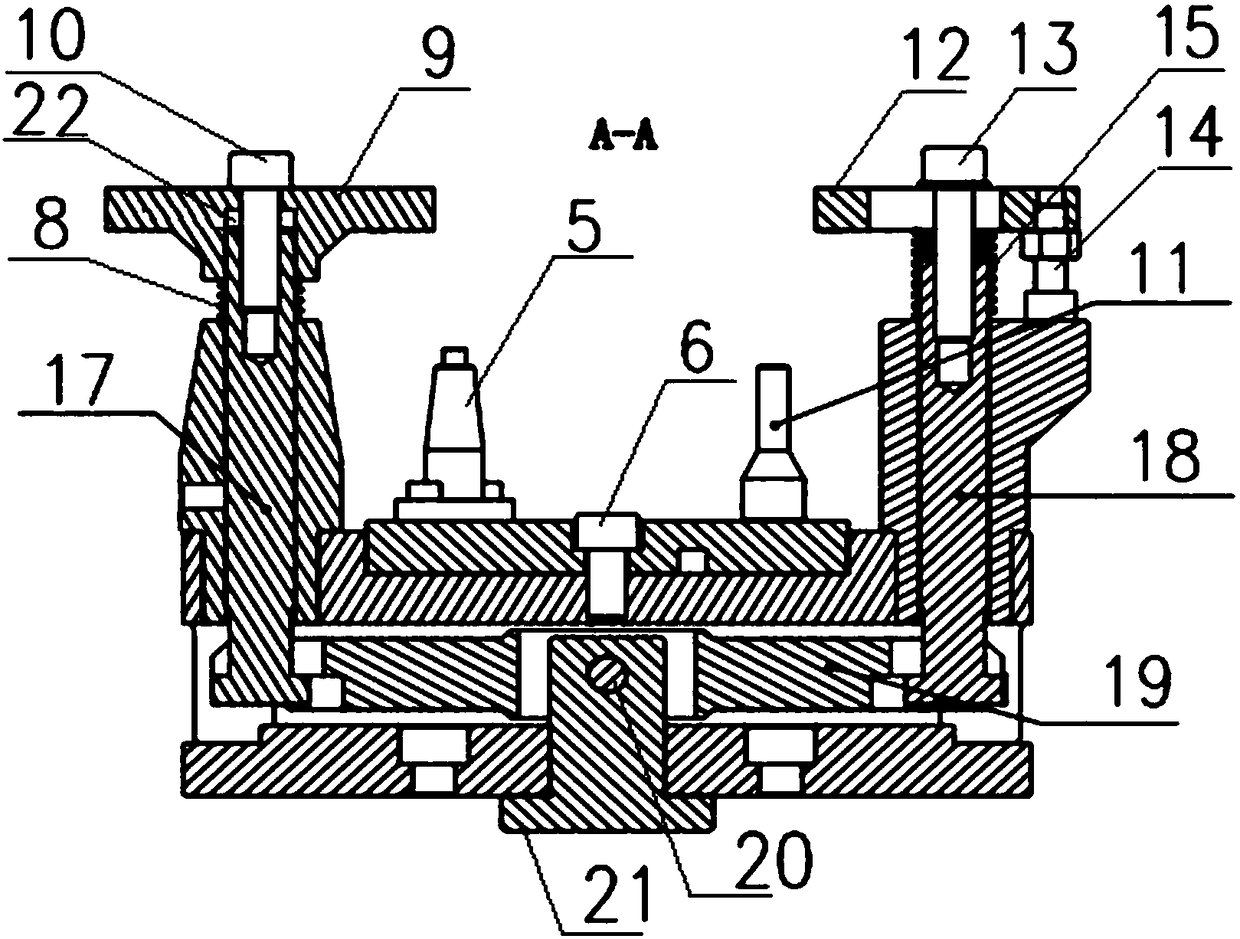

[0026] The present invention will be further described below in conjunction with the accompanying drawings:

[0027] like Figure 1-3 Shown: a fixture for processing the rear cover of an automobile air-conditioning compressor, including a connecting seat 1 fixed on the connecting flange 4, a positioning plate 3 is provided at the middle of the top end of the connecting seat 1, and the positioning plate 3 Positioning pins 5 and support columns 11 for positioning the back cover workpiece are respectively fixed on the upper part; a pressing device for pressing the back cover workpiece is provided on the connecting seat 1 outside the positioning plate 3 .

[0028] In a further solution, the pressing device includes a symmetrical left pressing device and a right pressing device, the left pressing device includes a left guide sleeve 7 arranged on the connecting seat 1, and the top end of the left guide sleeve 7 passes through The left spring 8 is connected with the rotary pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com