Automatic assembling machine for arc-shaped sealing strip of front windshield

A sealing strip and front windshield technology, applied in the field of auto parts production, can solve the problems of difficulty in increasing the production output of front windshield arc sealing strips, low work efficiency, poor consistency of manual assembly methods, etc., and achieve stable operation of equipment High performance, simple manual operation, simple action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

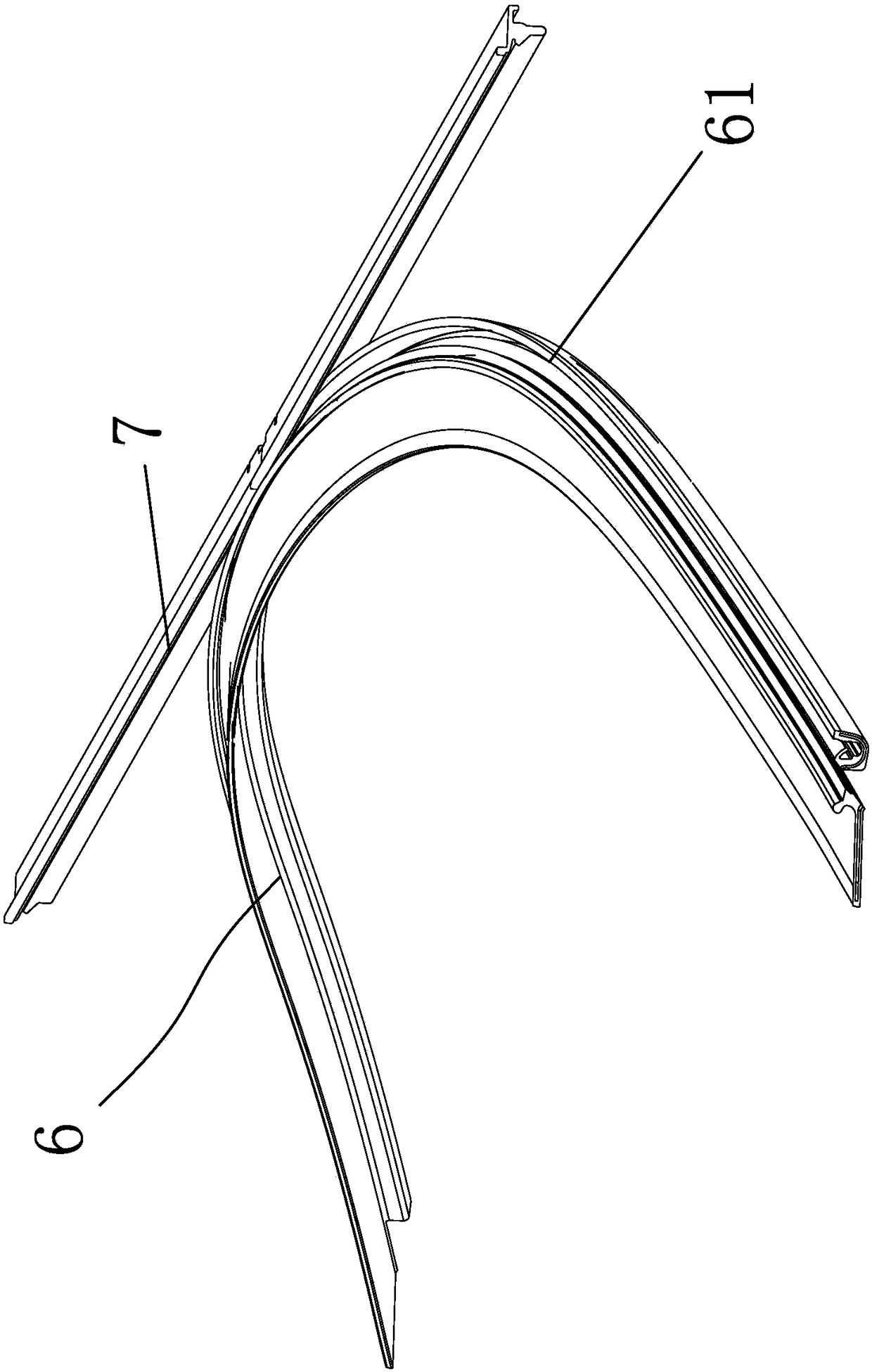

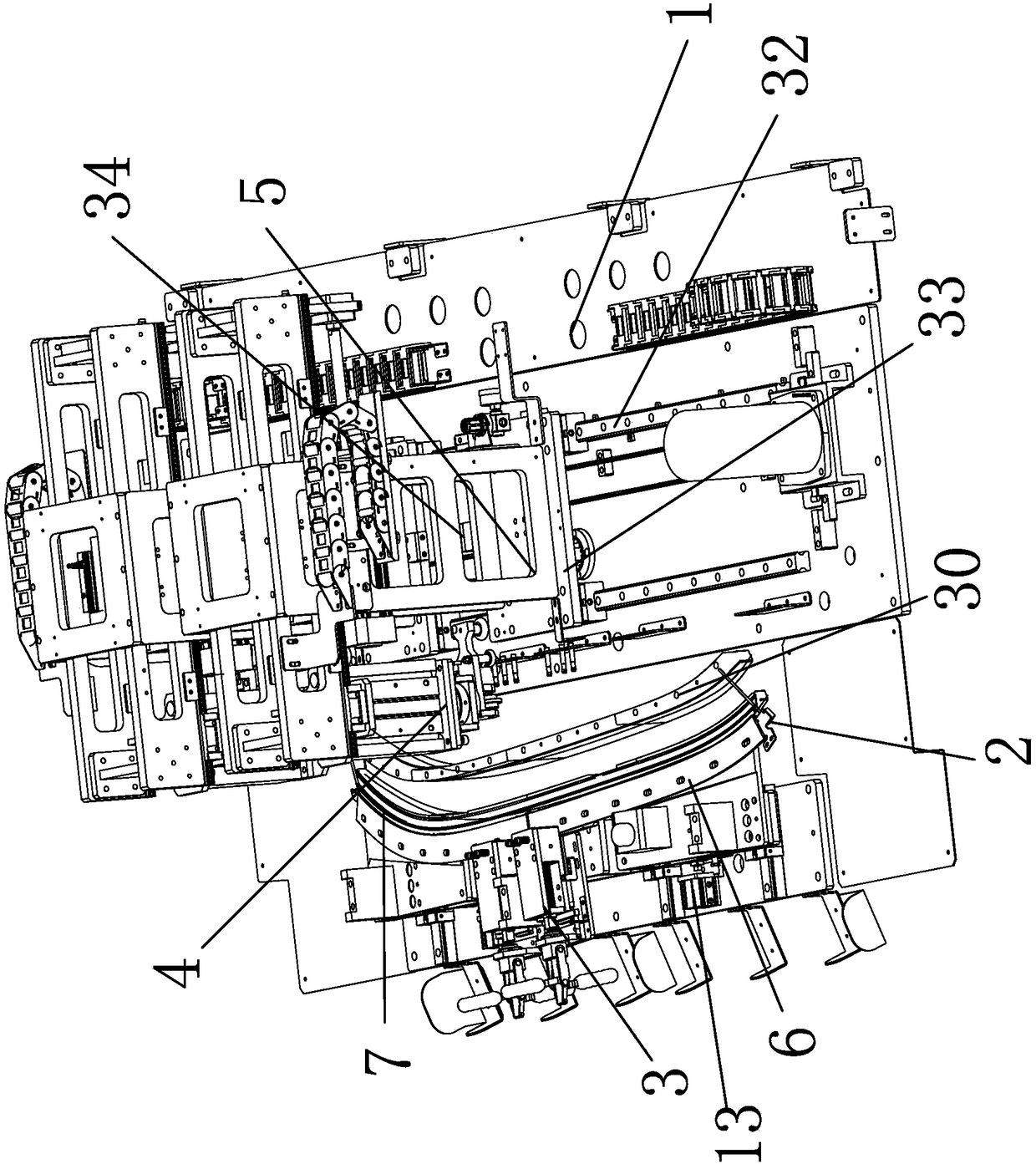

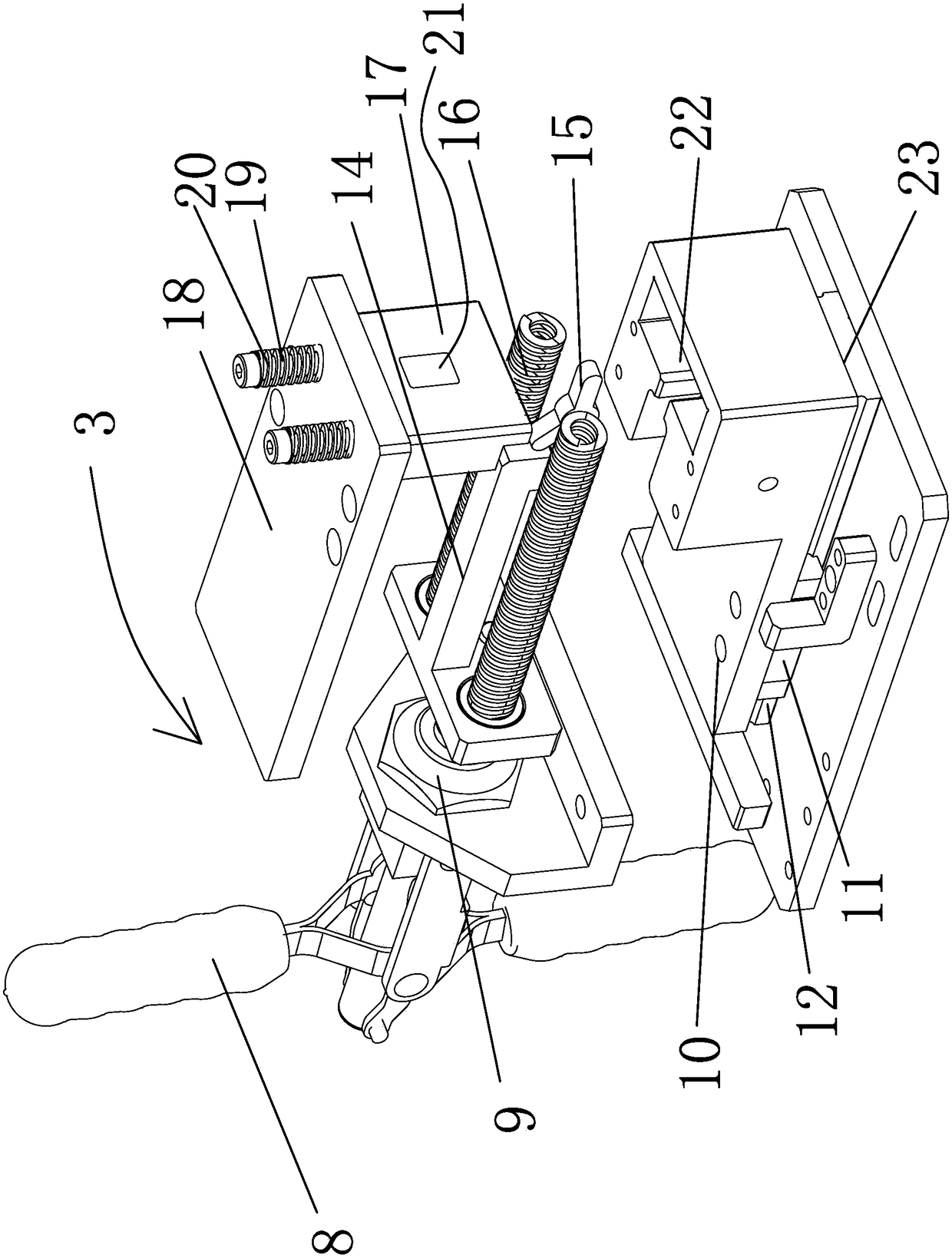

[0030] In the figure, main frame 1; product installation base 2; sliding clamping positioning component 3; floating pressing component 4; body 7; operating rod 8; connector 9; lower fixed block 10; sliding block 11; sliding guide rail 12; side pressure cylinder 13; Tighten the connecting plate 18; compress the movable rod 19; compress the spring 20; compress the driving port 21; press the lower groove 22; pre-press the edge 23; press into the cylinder 24; float and return the cylinder 25; Part 27; arc-shaped route limit roller 28; pressure wheel 29; route limit guide rail 30; drive bar 31; transverse guide rail 32; transverse sliding plate 33;

[0031] Such as figure 2As shown, the front windshield arc-shaped sealing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com