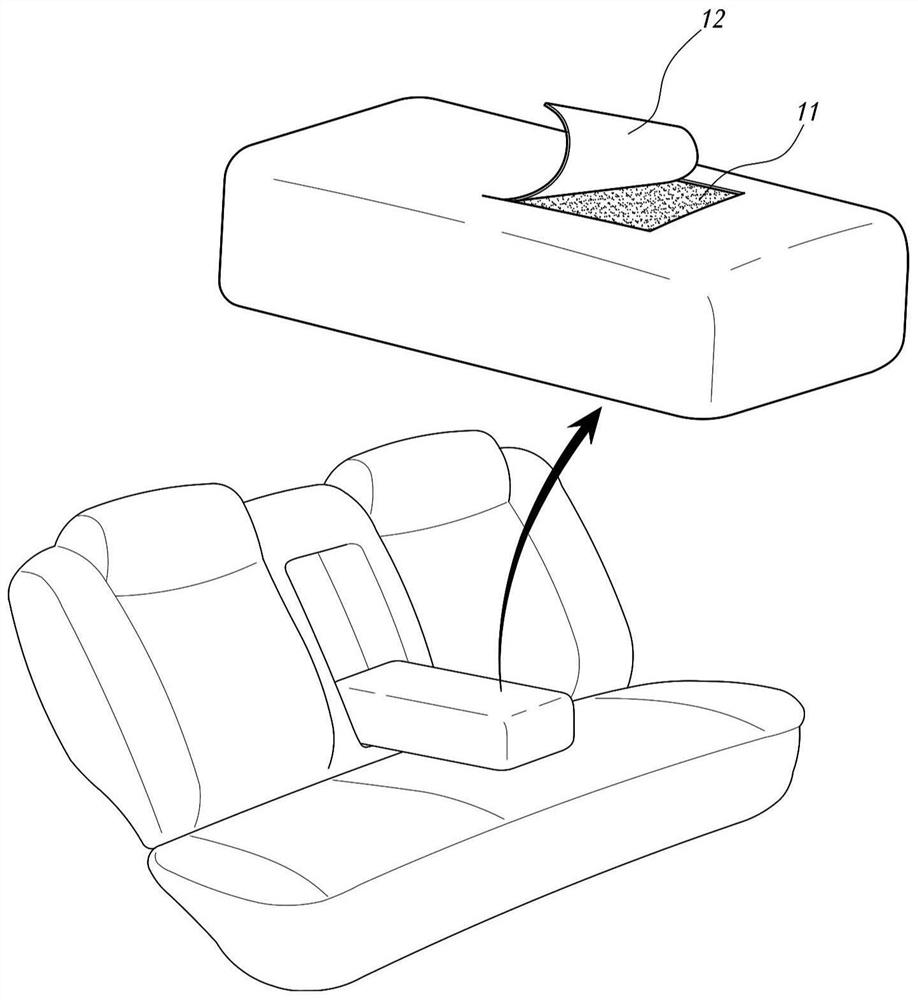

Car built-in armrest cover device

A technology for handrail covers and automobiles, which is applied in the directions of handrails, packaging, transportation and packaging, and can solve problems such as inability to manufacture handrails, automation limitations, and dependence on manual work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

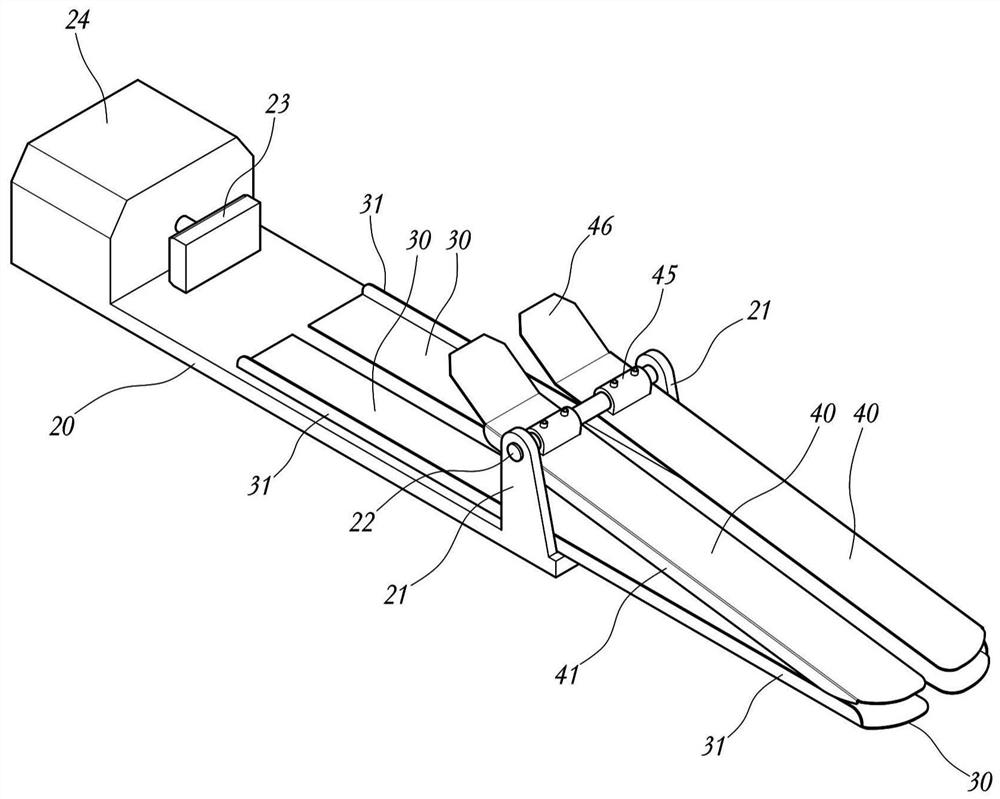

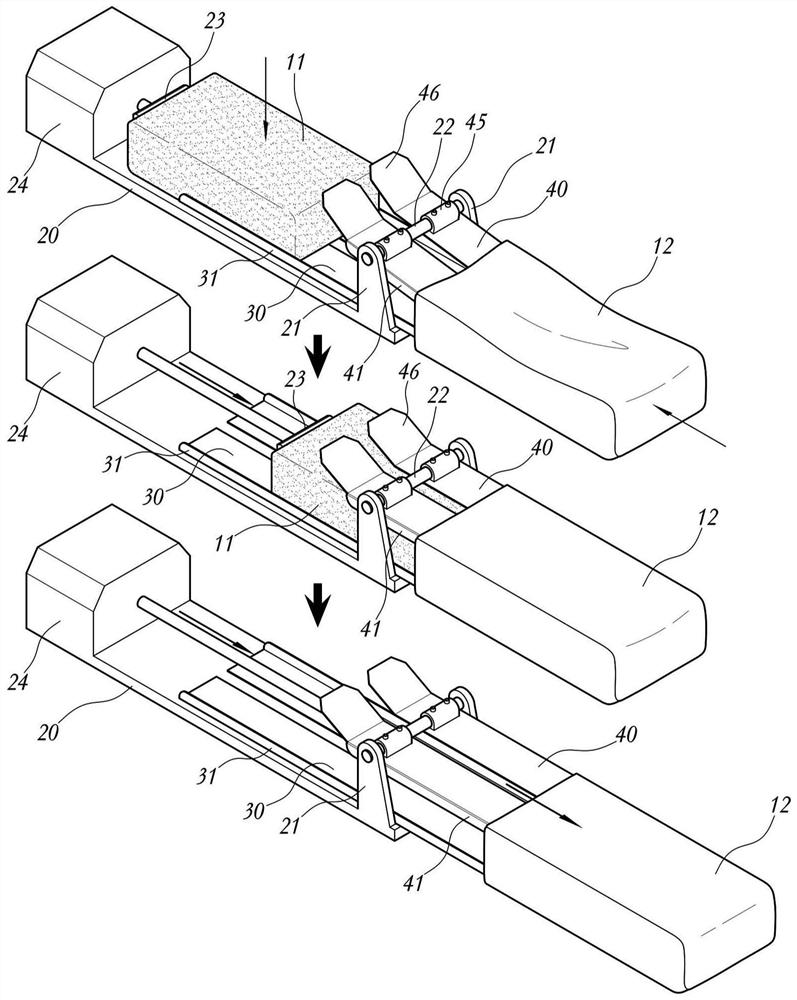

[0037] Next, with reference to the accompanying drawings, the specific structure and operating principle of the present invention will be described.

[0038] first, figure 2 It is a perspective view showing the appearance of the present invention. As shown in the figure, the present invention is a rectangular board when viewed from above. The bottom plate 30, the upper plate 40, etc. which are plate bodies protruding to the front side of the support stand 20 are comprised.

[0039] That is, if figure 2 As shown, a pair of base plates 30 are provided on the upper surface of the support platform 20, the front end of the base plate 30 protrudes toward the front of the support platform 20, and a bottom plate side wall 31 protruding upward is formed at the outer end of the base plate 30. A driving part 24 is formed at the rear end, and a two-way plate 23 is mounted on the driving part 24 .

[0040] In addition, brackets 21 protruding upward are respectively formed on the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com