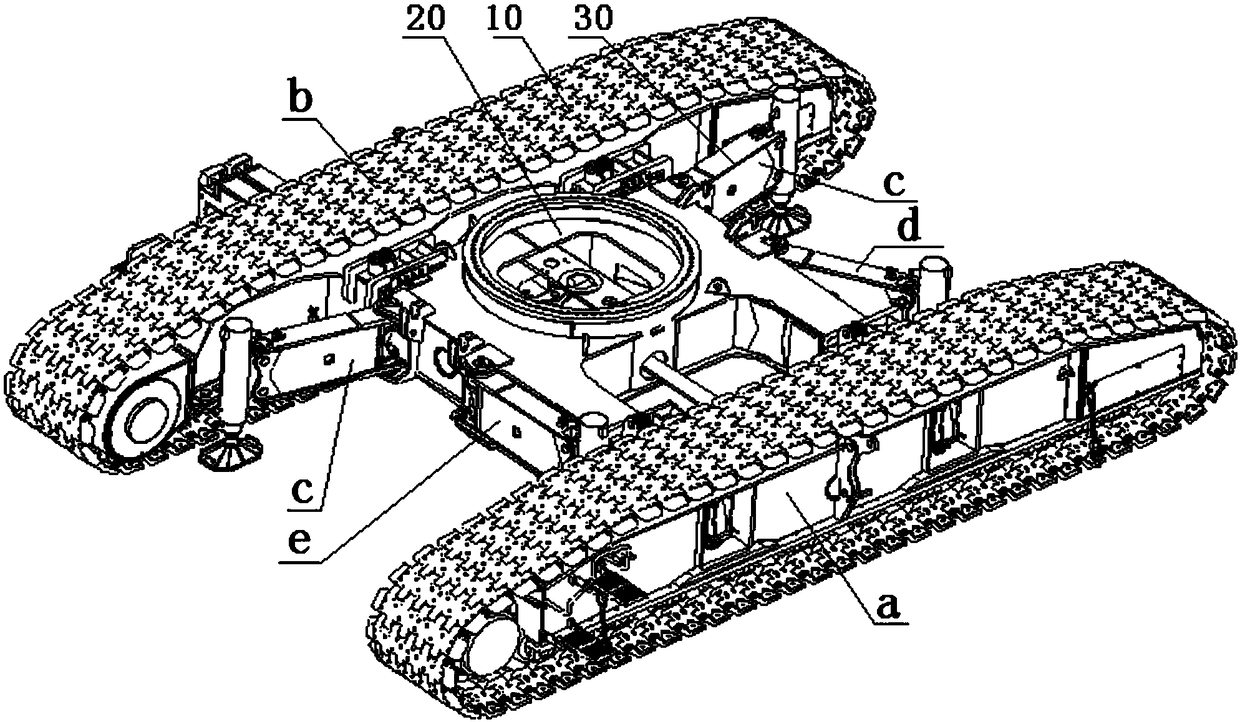

Vehicle frame structure with novel supporting leg seats and supporting legs

A frame structure and outrigger seat technology are used in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., which can solve the problems of low disassembly and assembly efficiency, inability to rotate, complex structure, etc. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

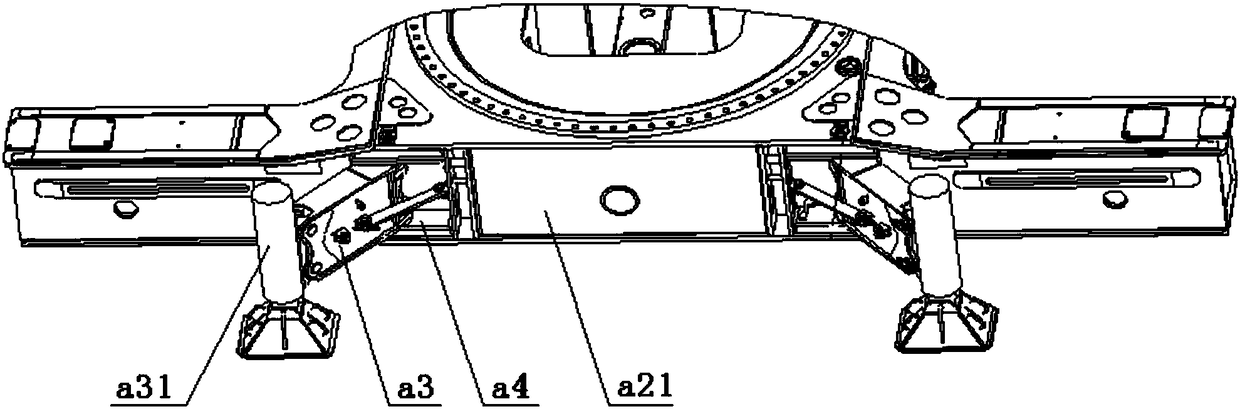

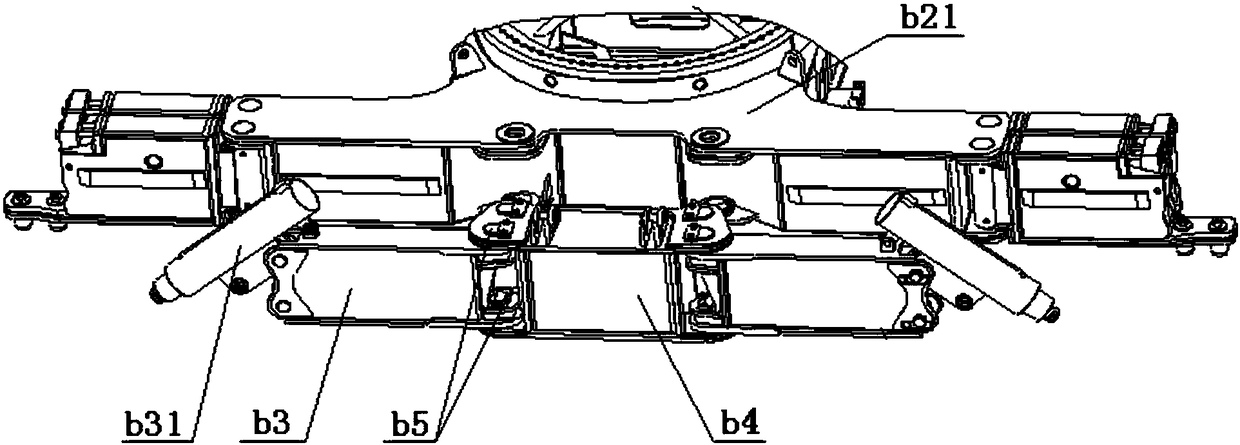

[0031] The invention makes full use of the space between the upper plane of the vehicle frame and the lower plane of the turntable, innovatively places the outrigger seat, outrigger, and even the outrigger oil cylinder in the transportation state in this space, solving the problem of outrigger seat, outrigger When placed in the front-to-back middle of the frame, it occupies the front-to-back dimension of the main structure of the frame and affects the bearing capacity of the frame and track frame. Specific as Pic 4-1 , Figure 4-2 , Figure 4-3 .

[0032] The frame 1 of the telescopic crawler chassis generally has a height difference between the section of the overhanging beam that undertak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com