Frame-leaf structure of a door and window system

A frame sash and window sash technology, applied in the field of frame sash structure, can solve the problems of high design and production cost, many types of materials, inconvenient installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

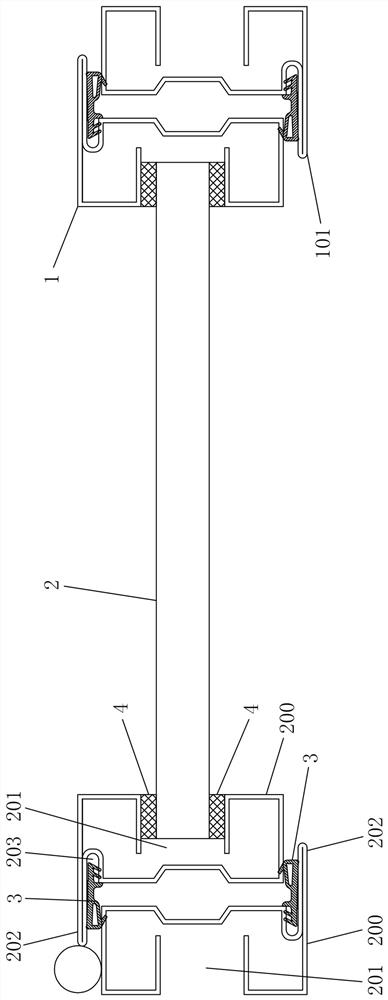

[0028] Such as figure 1 As shown, the frame structure of the door and window system of this embodiment includes a fan frame 101, and an openable window sash 1 is installed in the fan frame 101. The window sash 1 includes a frame body and a glass plate 2 installed in the frame body. The window sash 1 The frame body and the fan frame 101 are connected by load-bearing beams 200. One side of the load-bearing beam 200 is provided with a concave card slot 201, and the other side of the load-bearing beam 200 is provided with a rib 202. The rib 202 extends to the inside of the sash 101 and blocks the gap between the sash 1 and the sash 101 when the sash 1 is closed.

[0029] In this embodiment, the ribs 202 of the load-bearing beam 200 around the sash 101 are all located on the same side of the sash 101, so that the sash 1 can be rotated and opened to the other side of the sash 101 around the hinge point, and ensure that the sash 1 is closed with the sash 1. The fan frame 101 is flus...

Embodiment 2

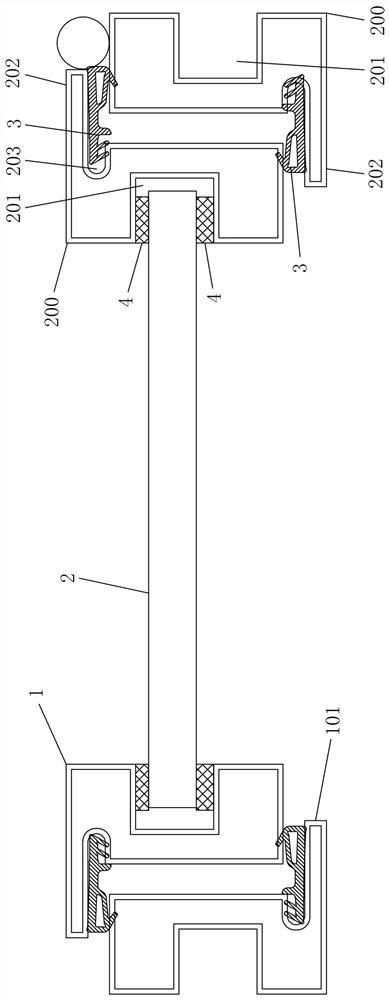

[0037] The frame and leaf structure of the door and window system of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as figure 2 As shown, in this embodiment, the load-bearing beam 200 is a closed profile, which has high strength and good load-bearing performance.

Embodiment 3

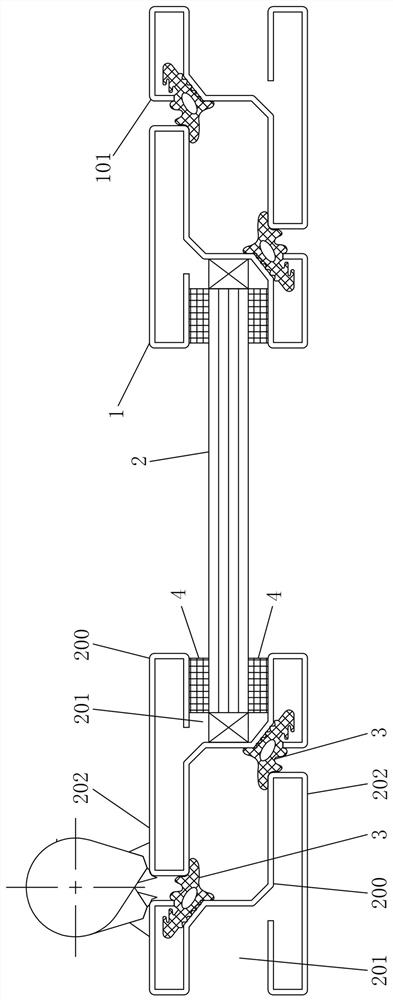

[0039] The frame and leaf structure of the door and window system of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as image 3 As shown, in this embodiment, one end of the plate of the load-bearing beam 200 in the form of an open profile is located on one side of the concave groove 201 , and the other end is located on one side of the rib 202 . And in the present embodiment, the first sealing strip 3 between the rib 202 of the load-bearing beam 200 of the frame of the sash 1 and the load-bearing beam 200 around the sash 101 is installed on the load-bearing beam 200 around the sash 101, and the sash 101 The first sealing strip 3 between the rib 202 of the surrounding load-bearing beam 200 and the load-bearing beam 200 connected to form the frame of the window sash 1 is installed on the load-bearing beam 200 connected to form the frame of the window sash 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com