Transmission device capable of widening gearbox speed ratio range

A transmission device and range technology, which is applied in the field of automobile transmission, can solve the problems of high manufacturing and use costs, and achieve the effect of meeting cost requirements and expanding the range of speed ratios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

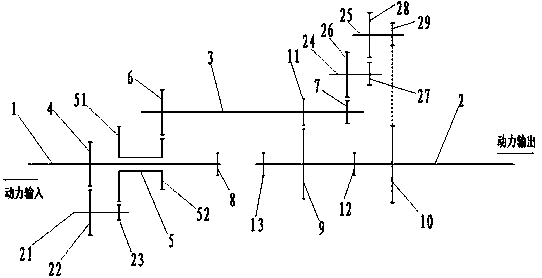

Embodiment 1

[0027] Such as figure 1 As shown, a transmission device for expanding the speed ratio range of the gearbox is characterized in that it includes a power input shaft 1, a power output shaft 2 and an intermediate shaft 3, and the power input shaft 1 and the power output shaft 2 are provided with a plurality of Gear driven gears, a gear synchronizer for realizing gear shifting is arranged between the multiple gears driven gears, and the gear driven gear of the highest gear among the multiple gears driven gears is set at On the end of the power input shaft 1 close to the power output shaft 2, the gear driven gears of each gear except the highest gear are arranged in the order of the gears from high to low along the direction of power output. On the power output shaft 2, the end of the power input shaft 1 away from the power output shaft 2 is provided with a power output driving gear 4, and the power between the gear driven gear of the highest gear and the power output driving gear ...

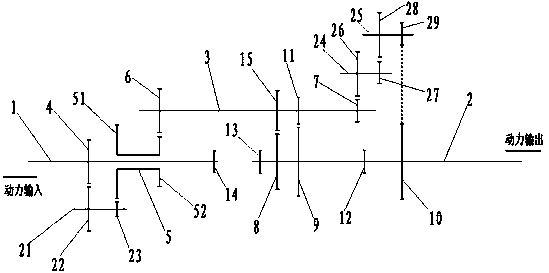

Embodiment 2

[0031] This embodiment is similar to Embodiment 1, the difference is that, as figure 2 As shown, the number of gear driven gears on the power input shaft 1 and the power output shaft 2 is four, which are respectively the fourth gear driven gear 14 on the power input shaft 1 and the gears on the power output shaft in turn. The third gear driven gear 8, the second gear driven gear 9 and the first gear driven gear 10 on the 2; The gear 8 and the third gear driving gear 15 and the second gear driving gear 11 meshed with the second gear driven gear 9; the number of the gear synchronizers is two, which are respectively located at the first gear driven gear 10 and the second gear. The first gear synchronizer 12 between the gear driven gears 9 and the second gear synchronizer 13 arranged between the third gear driven gear 8 and the fourth gear driven gear 14 . Other structures and working principles of this embodiment are the same as those of Embodiment 1.

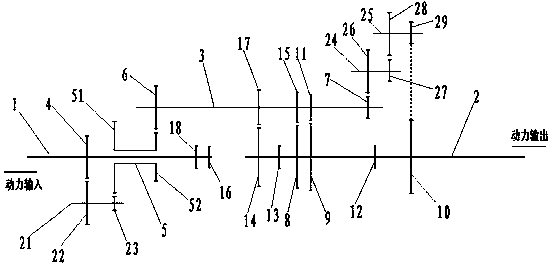

Embodiment 3

[0033] This embodiment is similar to Embodiment 1, the difference is that, as image 3 As shown, the number of gear driven gears on the power input shaft 1 and the power output shaft 2 is five, which are respectively the fifth gear driven gear 16 on the power input shaft 1 and the gears on the power output shaft in turn. The fourth gear driven gear 14 on the 2, the third gear driven gear 8, the second gear driven gear 9 and the first gear driven gear 10; the number of gear driving gears on the intermediate shaft 3 is three, respectively The fourth gear driving gear 17, the third gear driving gear 15 and the second gear driving gear 11 meshed with the fourth gear driven gear 14, the third gear driven gear 8 and the second gear driven gear 9; the gear synchronizer The number is three, which are the first gear synchronizer 12 arranged between the first gear driven gear 10 and the second gear driven gear 9, the third gear driven gear 8 and the fourth gear driven gear 9. The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com