Hybrid power driving system and vehicle

A drive system and hybrid technology, applied in hybrid vehicles, engine-driven traction, motor vehicles, etc., can solve the problem of high cost, and achieve the effects of strong flexibility, simple overall structure, and reduced volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

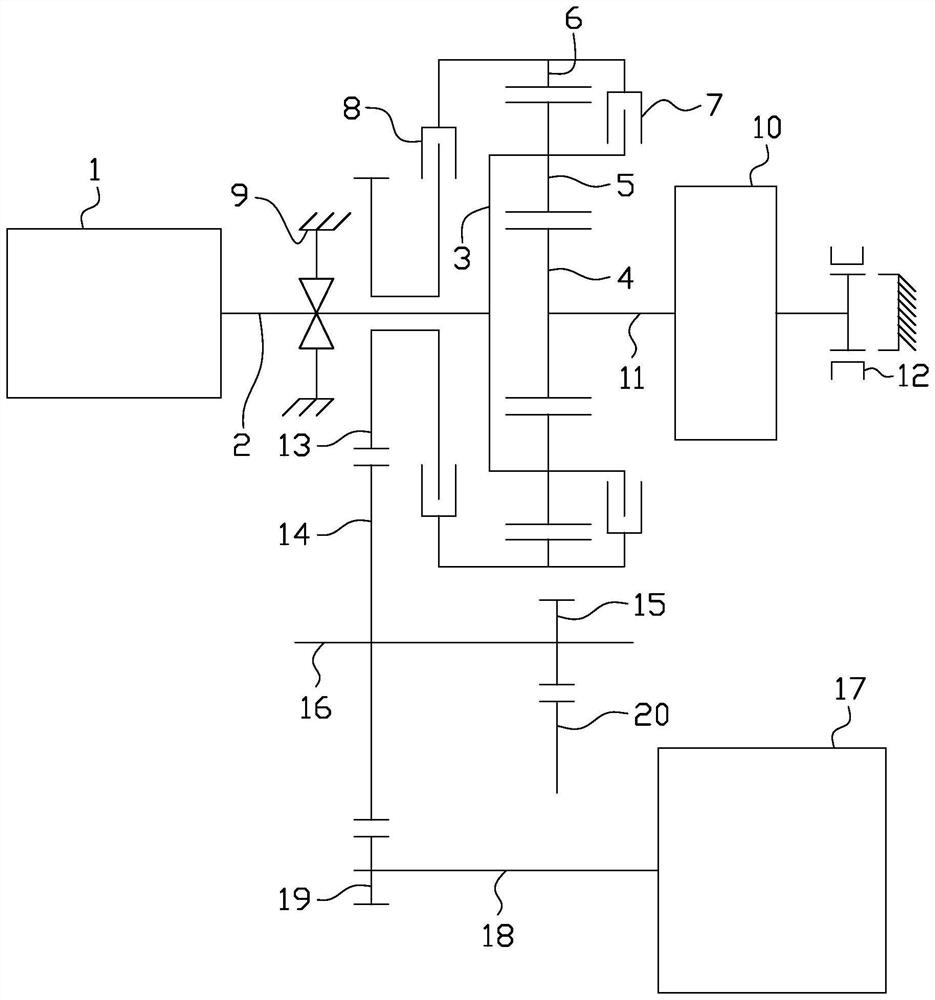

[0038] figure 1 is a schematic structural diagram of the hybrid drive system in the first embodiment of the present invention. like figure 1 As shown, the hybrid drive system of this embodiment includes an engine 1, a first shaft 2, a planetary row, a first clutch 7, a second clutch 8, a braking device 9, a generator 10, a second shaft 11, a brake 12, The first gear 13 , the second gear 14 , the third gear 15 , the third shaft 16 , the drive motor 17 , the fourth shaft 18 , the fourth gear 19 and the differential 20 . Wherein, the planet row includes a planet carrier 3 , a sun gear 4 , a planet gear 5 and a ring gear 6 .

[0039] The engine 1 is connected to the first shaft 2 , the generator 10 is connected to the second shaft 11 , and the driving motor 17 is connected to the fourth shaft 18 . Specifically, the first shaft 2 is the output shaft of the engine 1 , the second shaft 11 is the output shaft of the generator 10 , and the fourth shaft 18 is the output shaft of the ...

no. 2 example

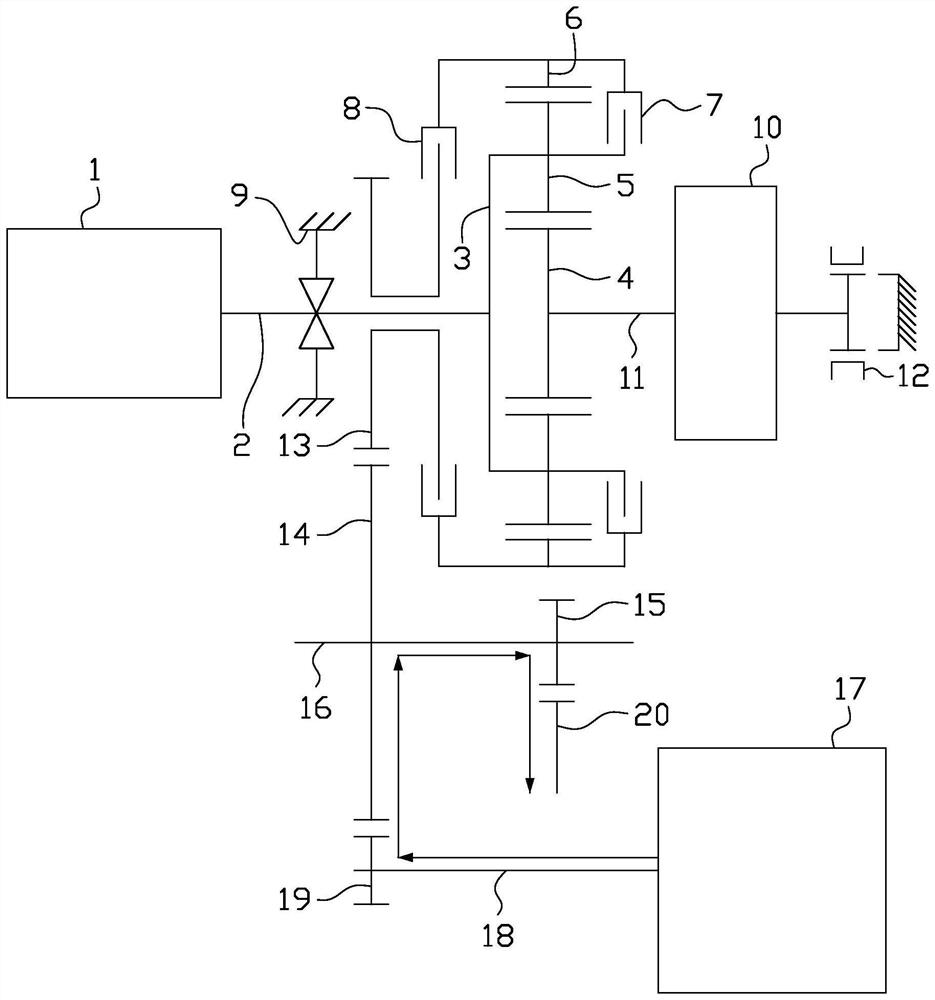

[0074] Figure 9 It is a schematic structural diagram of a hybrid drive system according to the second embodiment of the present invention. like Figure 9 As shown, the hybrid drive system of this embodiment is basically the same as that of the above-mentioned first embodiment, the only difference is that in this embodiment, the differential 20 meshes with the second gear 14, and the fourth gear 19 meshes with the third gear 15 meshes.

[0075] For other structures and working modes of this embodiment, reference may be made to the above-mentioned first embodiment, which will not be repeated here.

no. 3 example

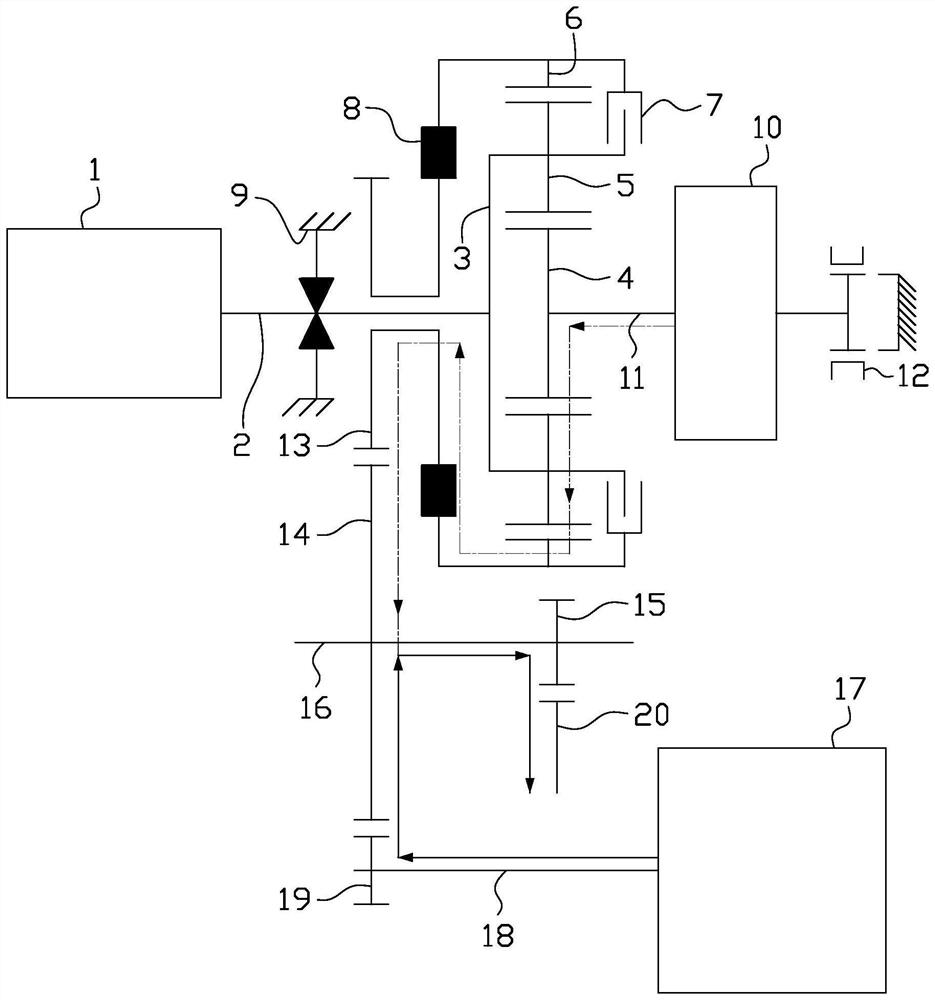

[0077] Figure 10 It is a schematic structural diagram of a hybrid drive system according to the third embodiment of the present invention. like Figure 10 As shown, the hybrid drive system of this embodiment is basically the same as that of the above-mentioned first embodiment, the only difference is that in this embodiment, the braking device 9 is specifically a brake. In the dual-motor pure electric mode, the engine 1 does not work, but the generator 10 outputs power. At this time, the brake works and brakes the first shaft 2 and the planet carrier 3, while in other modes, the brake does not work ( That is, the first shaft 2 and the planet carrier 3 are not braked).

[0078] For other structures and working modes of this embodiment, reference may be made to the above-mentioned first embodiment, which will not be repeated here.

[0079] Further, the present invention also provides a vehicle, including the above-mentioned hybrid drive system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com