Water cooling head

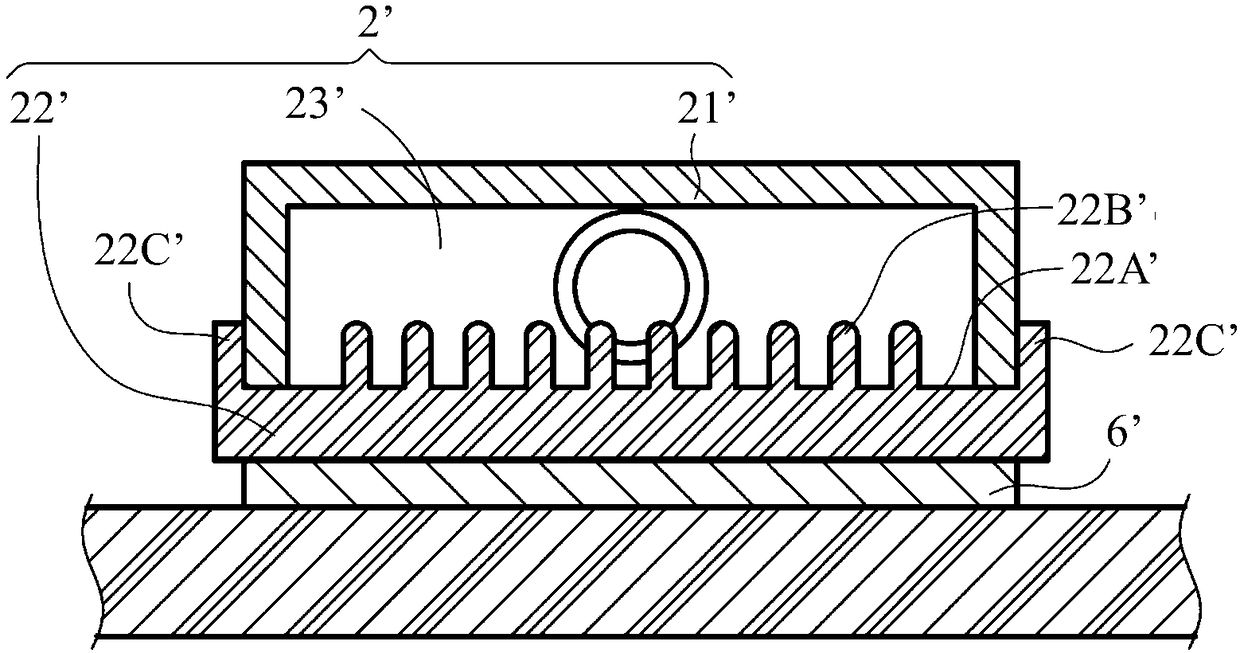

A water-cooled head, three-dimensional technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the difficulty of adding fins 22B', it is difficult to take into account the thermal conductivity of the base and the heat dissipation efficiency of the fins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

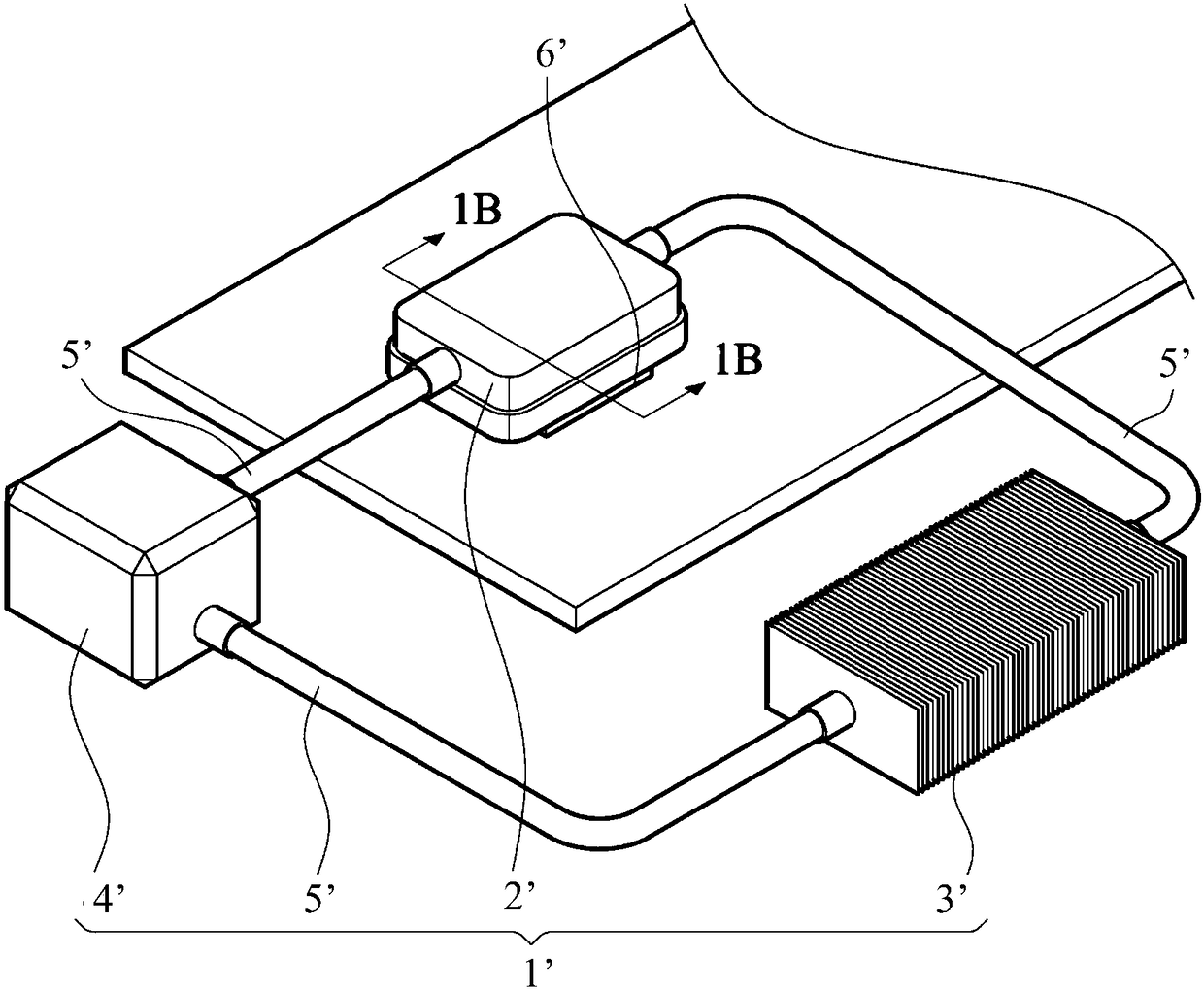

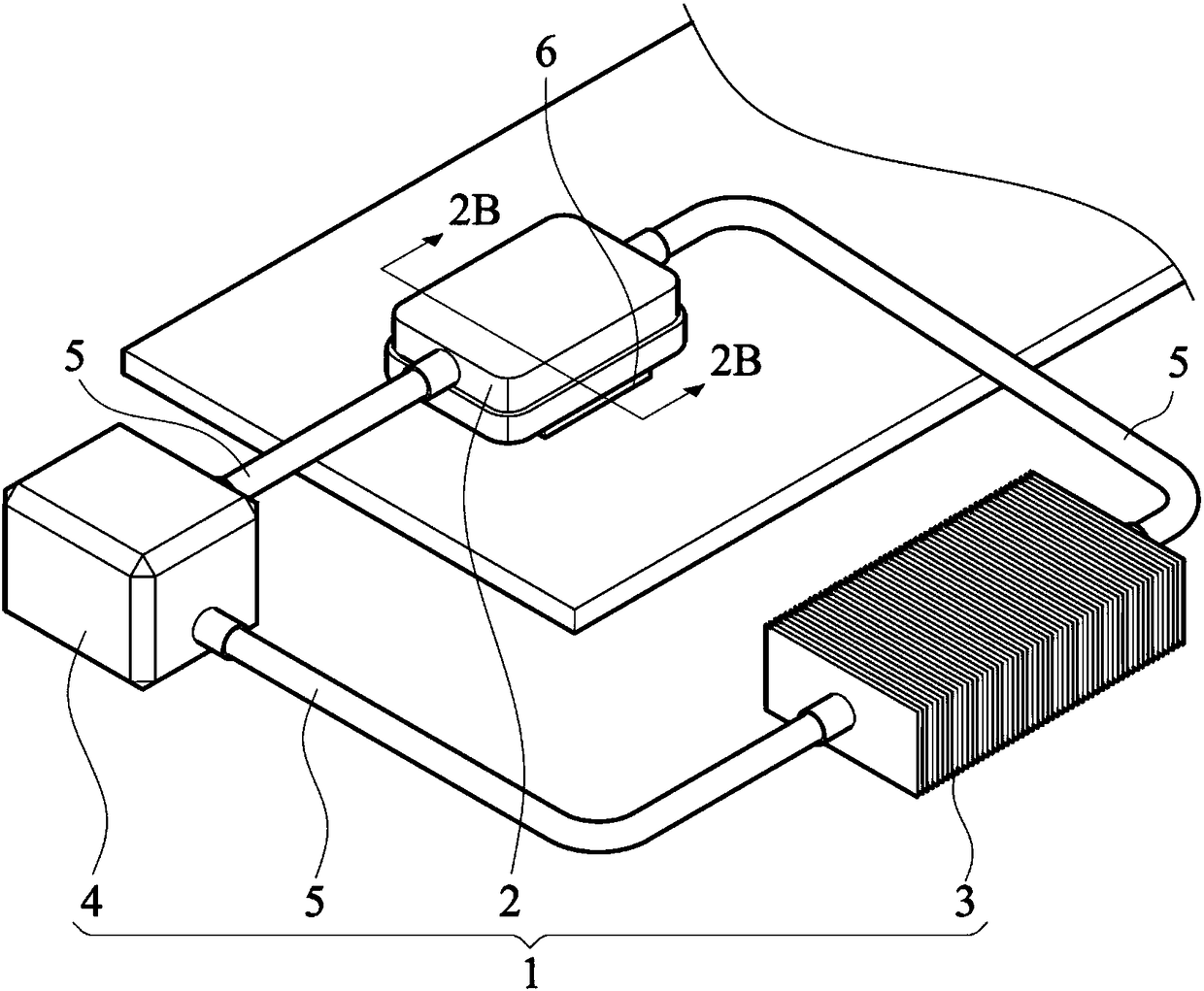

[0041] Figure 2A It is a three-dimensional schematic diagram of the water-cooling assembly proposed by an embodiment of the present invention. The water-cooling assembly 1 proposed in this embodiment is also composed of a water-cooling head 2, a water-cooling row 3, a pump 4 and a pipeline 5 to form a circulation path. The circulation path is filled with working fluid (not shown in the figure). When the water-cooling assembly 1 of this embodiment is in operation, the water-cooling head 2 will be in contact with the heat source 6 such as a chip, a memory or a light-emitting element, etc. At this time, the working fluid in the water-cooling head 2 will absorb the heat energy generated by the heat source 6 and The temperature is raised, and the temperature is lowered through the pipeline 5 to the water-cooled row 3 for heat exchange. Finally, the cooled working fluid will be sent back to the water-cooled head 2 for the next cycle. The water cooling assembly 1 may be provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com