Preparation method of ceramic powder for metal-based ceramic copper-clad plate

A technology of ceramic copper clad laminate and ceramic powder, applied in the field of ceramic powder, can solve problems such as inability to mass-produce, product size limitation, and reduced thermal conductivity, and achieve stable and reliable effects, smooth production process, and lower sintering temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

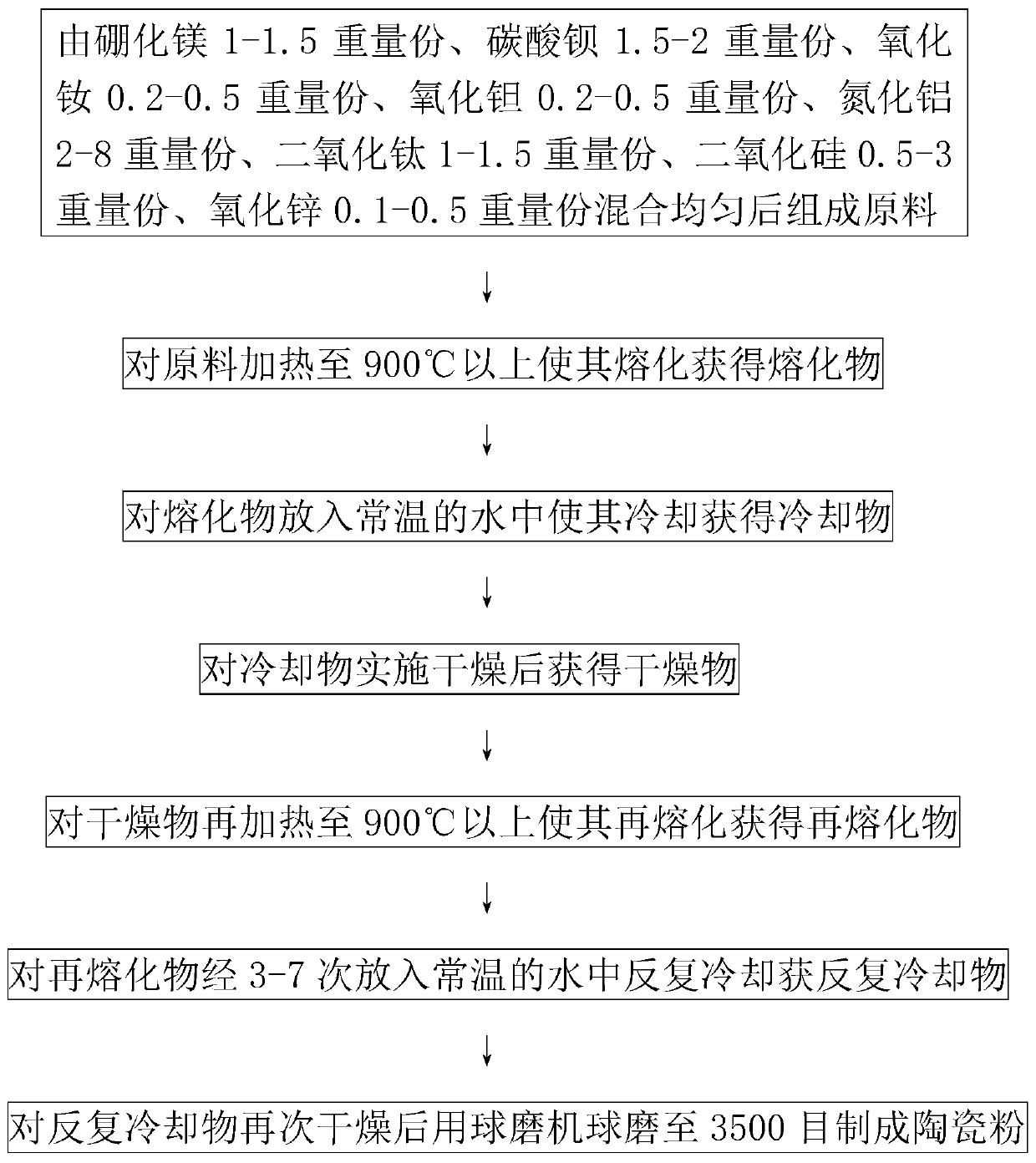

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 Shown:

[0025] A method for preparing ceramic powder for metal-based ceramic copper-clad laminates, comprising 1-1.5 parts by weight of magnesium boride, 1.5-2 parts by weight of barium carbonate, 0.2-0.5 parts by weight of neodymium oxide, 0.2-0.5 parts by weight of tantalum oxide, and aluminum nitride 2-8 parts by weight, 1-1.5 parts by weight of titanium dioxide, 0.5-3 parts by weight of silicon dioxide, and 0.1-0.5 parts by weight of zinc oxide are uniformly mixed to form raw materials, and the raw materials are heated to above 900°C to melt to obtain a melt , putting the melted product into normal temperature water to cool it to obtain a cooled product, drying the cooled product to obtain a dried product, reheating the dried product to above 900° C. to remelt it to obtain a remelted product, The remelted product is put into no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com