Functional gradient cast iron material and preparation method thereof

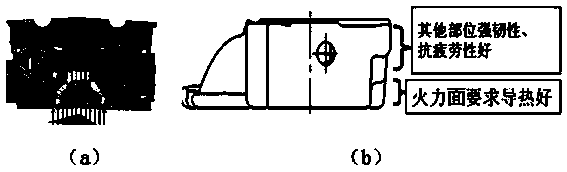

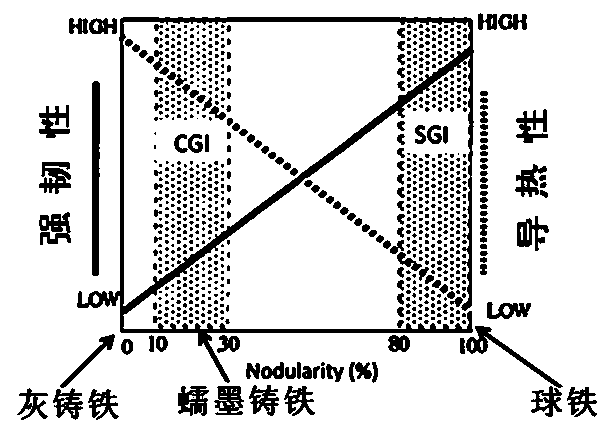

A functionally graded, cast iron technology, applied in the field of metal materials, can solve problems such as toughness, thermal conductivity, fatigue resistance, and oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A functionally graded cast iron material, which is composed of materials perpendicular to the fire surface of the cast iron cylinder head along the height direction: 5mm thick nodular cast iron, 2mm thick gray cast iron, and vermicular graphite cast iron for other parts of the cylinder head (see Figure 4 ).

[0036] The basic chemical composition of three kinds of cast iron is: its chemical composition is respectively by weight percentage:

[0037] C: 3.6%, Si: 2.1%, Mn: 0.2%, Cu: 0.3%, Mo: 0.2%, Cr: 0.1%, Sn: 0.02%, the rest is composed of iron and unavoidable impurities, and its carbon equivalent is 4.3 ; The inoculant and the modificator are 75 silicon-iron and magnesium-rare earth creeping agents respectively, and the particle size of the 75 silicon-iron and magnesium-rare earth creeping agents are both 2mm.

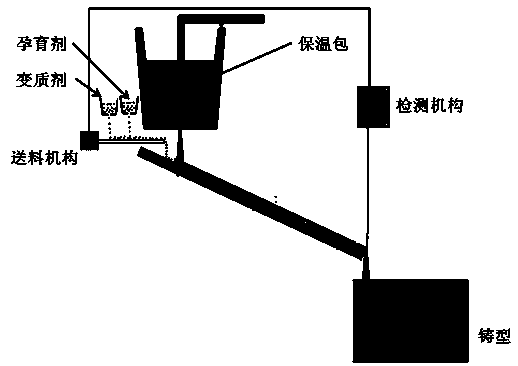

[0038] The preparation method of the functionally graded cast iron material is: comprising the following preparation steps:

[0039] a. Alloy melting: Use ...

Embodiment 2

[0044] A functionally graded cast iron material, which is composed of materials perpendicular to the fire surface of the cast iron cylinder head along the height direction: 5mm thick nodular cast iron, 8mm thick gray cast iron, and vermicular graphite cast iron for other parts of the cylinder head (see Figure 4 ).

[0045] The basic chemical composition of the three cast irons is: C: 3.7%, Si: 2.2%, Mn: 0.3%, Cu: 0.4%, Mo: 0.2%, Cr: 0.1%, Sn: 0.04%, the rest is iron and unavoidable The impurity composition is 4.4 carbon equivalent; the inoculant and the modificator are commercially available 75 silicon-iron and magnesium-rare earth creeping agents, respectively, with a particle size of 4mm.

[0046] The preparation method of the functionally graded cast iron material is as follows:

[0047] a. Alloy melting: Use a medium frequency induction furnace to melt the required cast iron alloy, pour it into the insulation bag after it is out of the furnace, and control it at 1480°C.

...

Embodiment 3

[0052] The functional gradient cast iron material prepared by the present invention is composed of materials perpendicular to the fire surface of the cast iron cylinder head along the height direction: 9mm thick nodular cast iron, 10mm thick gray cast iron, and other parts of the cylinder head are vermicular graphite cast iron (see Figure 5 );

[0053] The basic chemical composition of the three cast irons is: C: 3.7%, Si: 2.2%, Mn: 0.3%, Cu: 0.4%, Mo: 0.2%, Cr: 0.1%, Sn: 0.04%, the rest is iron and unavoidable The impurity composition is 4.4 carbon equivalent; the inoculant and the modificator are commercially available 75 silicon-iron and magnesium-rare earth creeping agents, respectively, with a particle size of 4mm.

[0054] The preparation method of the functionally graded cast iron material is as follows:

[0055] a. Alloy melting: Use a medium frequency induction furnace to melt the required cast iron alloy, pour it into the insulation bag after it is released, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com