Lubricant compositions for an automatic transmission

A technology of lubricating oil composition and automatic transmission, applied in the directions of lubricating composition, petroleum industry, additives, etc., to achieve the effects of long fatigue life, low temperature viscosity characteristics, good oxidation stability, and excellent balance ability

Inactive Publication Date: 2007-10-24

NIPPON OIL CO LTD +1

View PDF7 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, any such lubricating oil composition is excellent in anti-shake maintenance performance, low-temperature viscosity characteristics, and oxidation stability, but can achieve a transmission that is excellent in performance such as anti-friction characteristics, fuel-saving characteristics, and gear fatigue resistance characteristics. The oil is really rare, still looking forward to further improvement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~3

[0145] Examples 1 to 3; Comparative Examples 1 to 9

[0146] According to the combinations shown in Table 1, the automatic transmission lubricating oil compositions according to the present invention (Examples 1 to 3) were prepared. About these compositions, the performance evaluation test shown below was performed. The results are shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Login to View More

Abstract

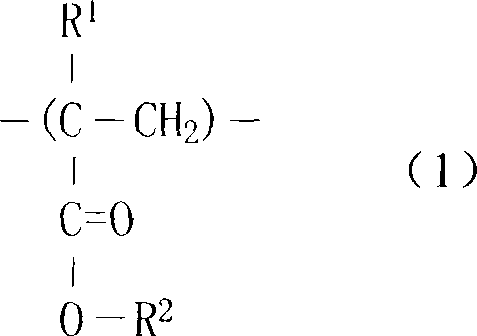

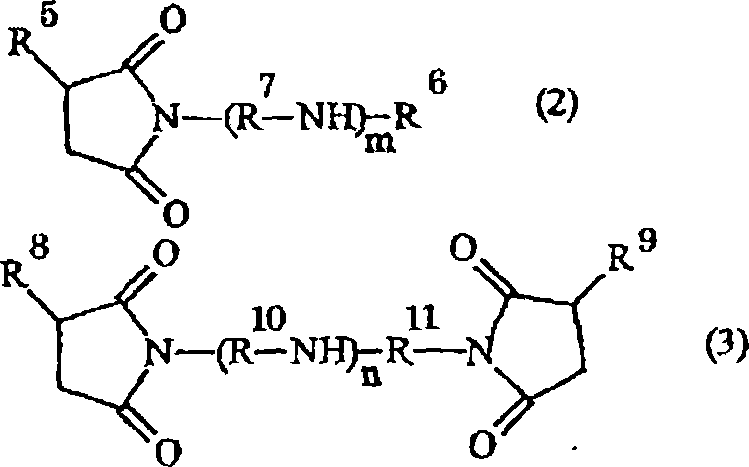

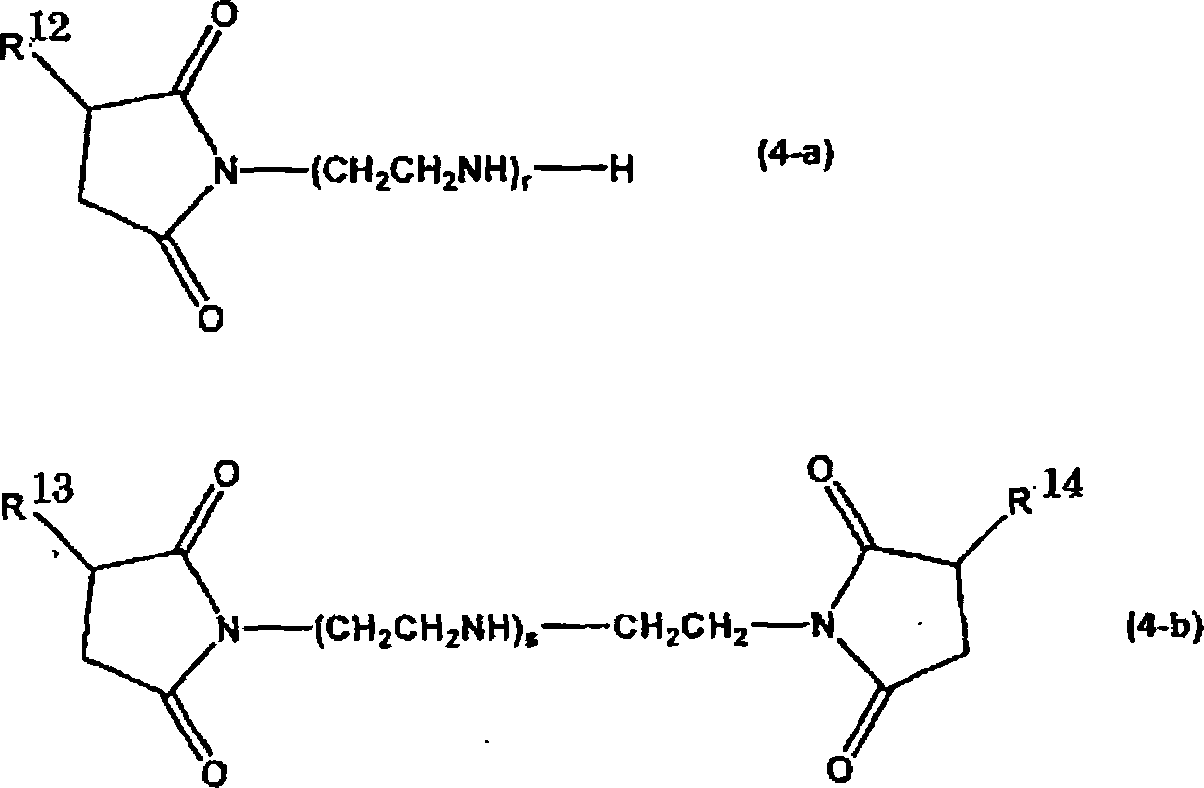

The invention provides a lubricant composition for automatic transmissions excellent in sustainability of anti-shudder property, low-temperature viscosity characteristics, and oxidation stability, and excellent and well-balanced in durability of friction characteristics, energy-conserving performance, and anti-fatigue performance on gears. The composition contains a base oil having a kinematic viscosity at 100 DEG C. of 3.7-4.1 mm<2> / s, and composed of base oil having the viscosity of 2.5-4.5 mm<2> / s, and base oil having the viscosity of 10-40 mm<2> / s; 1-20 mass % poly(meth)acrylate viscosity index improver having Mw of 15000-300.00; 2-4 mass % imide friction modifier having a C8-C30 hydrocarbon group; 0.01-0.04 mass % phosphorus extreme pressure agent in terms of phosphorus; and 0.01-0.04 mass % ashless dispersant having at least one alkyl or alkenyl group of a number average molecular weight of >=2000 in terms of nitrogen, all with respect to the total amount of the composition, and has the viscosity of 5.6-5.8 mm<2> / s.

Description

Technical field [0001] The present invention relates to a lubricating oil composition for automatic transmissions, in particular to a long fatigue life even at low viscosity, and excellent overall performance in terms of anti-shake maintenance performance, low-temperature viscosity characteristics, oxidation stability, and anti-friction characteristics. It is well-balanced and is suitable for the lubricating oil composition for automobile automatic transmission. Background technique [0002] In recent years, based on environmental protection issues such as carbon dioxide emission reduction, the energy saving of automobiles, that is, fuel consumption has become a top priority, and the improvement of engines or automatic transmissions is strongly required to contribute to energy conservation. Therefore, the lubricating oil used in these products is required to reduce the stirring resistance or friction resistance more than before. [0003] As a measure to save fuel consumption in a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M145/14C10M133/56C10M137/00C10N30/02C10N30/06C10N40/04

CPCC10N2240/042C10M169/04C10M2215/28C10M2209/084C10N2230/10C10M2223/049C10N2230/02C10N2230/06C10N2230/08C10M2223/045C10M2205/028C10M2203/10C10N2220/022C10M2215/086C10N2020/02C10N2030/02C10N2030/06C10N2030/08C10N2030/10C10N2040/042C10N2020/04C10M137/00C10M171/02

Inventor 伊东政朗村上靖宏荒川庆江前田诚杉山贵广

Owner NIPPON OIL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com