Cooling wire for motor

A technology of wires and hollow blocks, applied in the direction of power cables, circuits, electrical components, etc., can solve the problems of wire burning and other problems, and achieve the effect of avoiding wire burning and preventing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

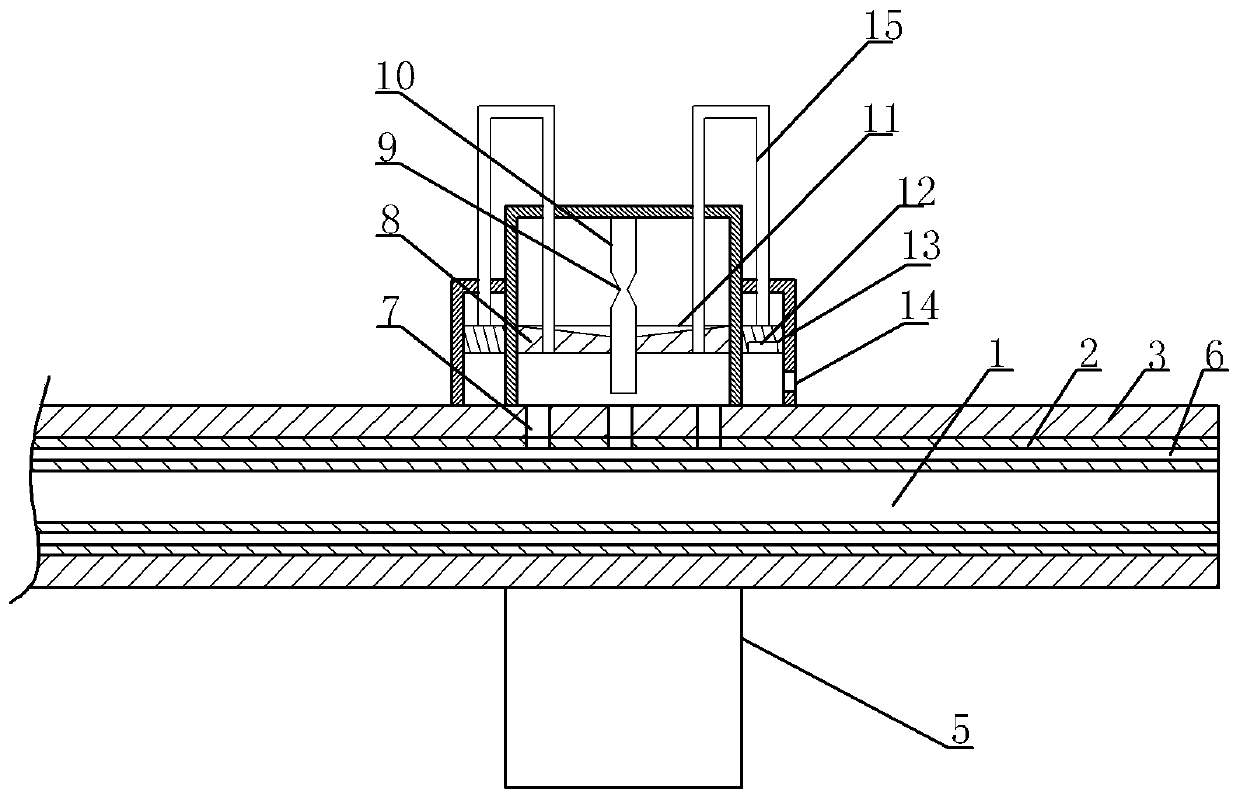

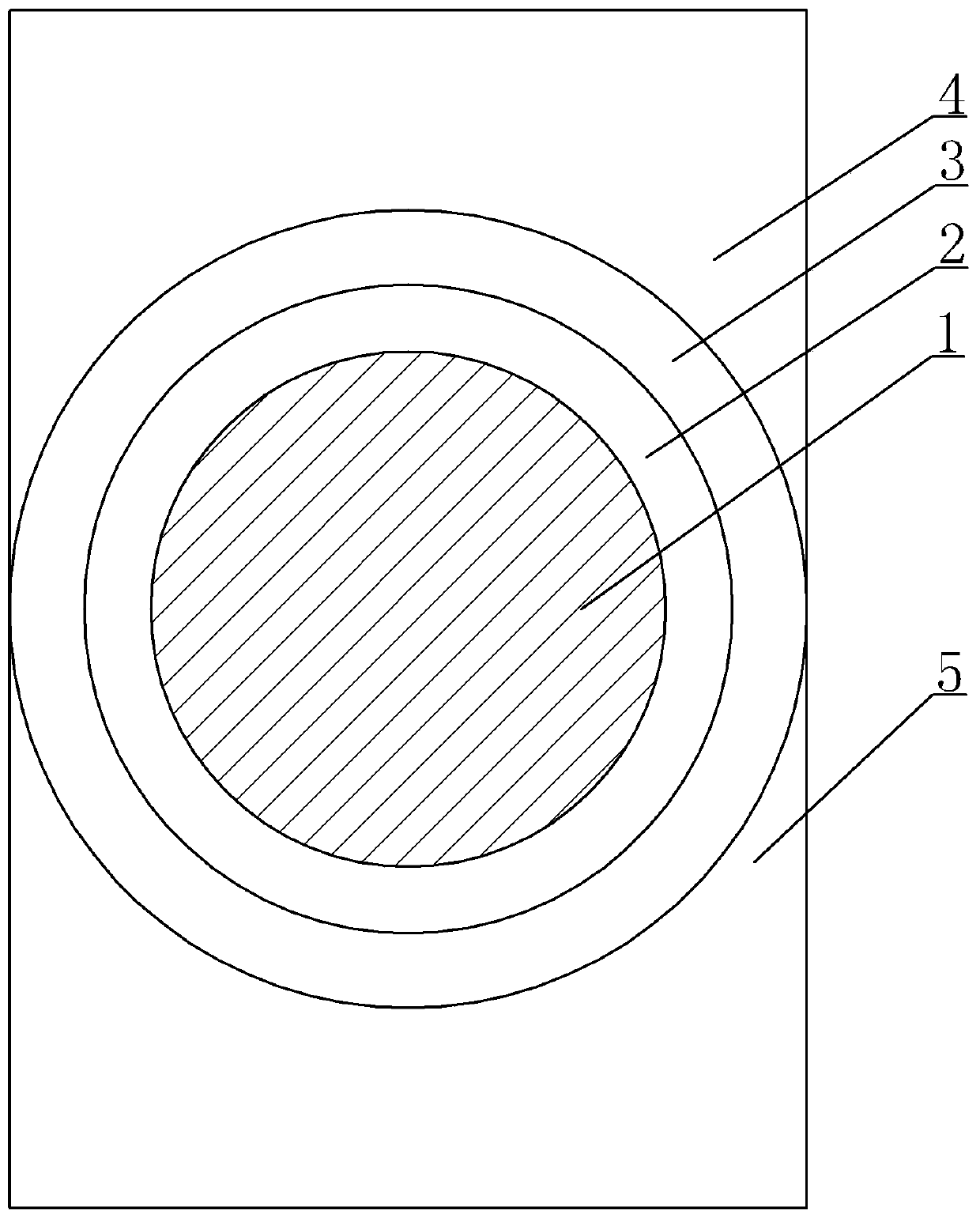

[0022] as attached figure 1 And attached figure 2 As shown, a cooling wire for a motor includes a conductor 1, an asbestos layer 2 and an insulating layer 3 in sequence from the inside to the outside. The asbestos layer 2 is provided with a water storage chamber 6 and a through hole 7 communicating with the water storage chamber 6. A temperature detector for detecting the temperature of the water storage chamber 6 is installed in the water storage chamber 6. The detection part of the temperature detector is located in the storage chamber. In the water cavity, the display part of the temperature detector is located at the support block 5 . The asbestos layer 2 can provide a certain heat insulation effect on the conductor 1 to prevent the high temperature of the conductor 1 from directly burning out the insulating layer 3 . The upper part of the insulating layer 3 is fixed with several cooling mechanisms 4 at intervals by glue. When the conductor 1 is overloaded due to materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com