Coil insertion method and coil insertion device

A coil insertion and coil technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problem of enlarged coil end size, achieve the effect of reducing insertion load and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

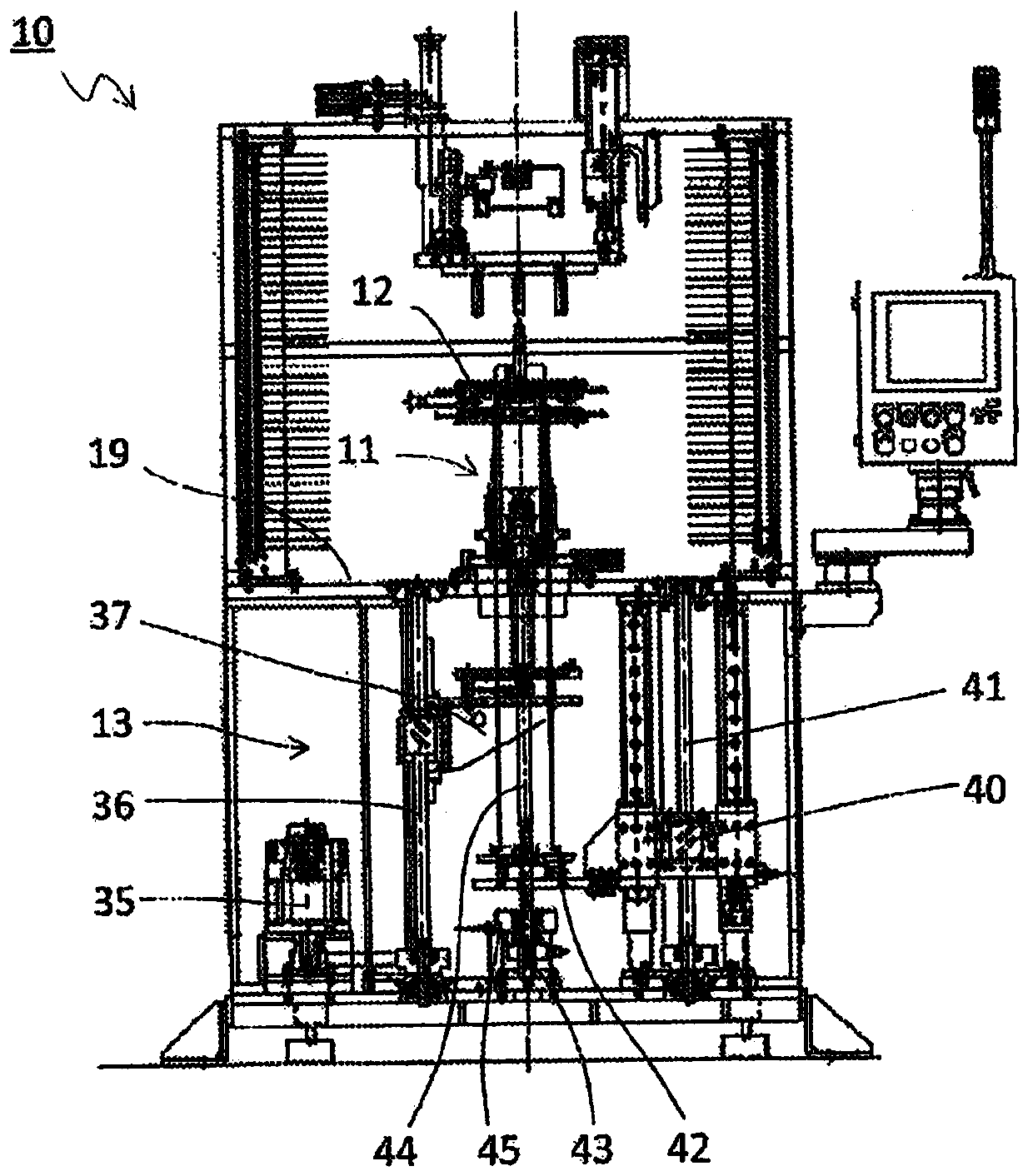

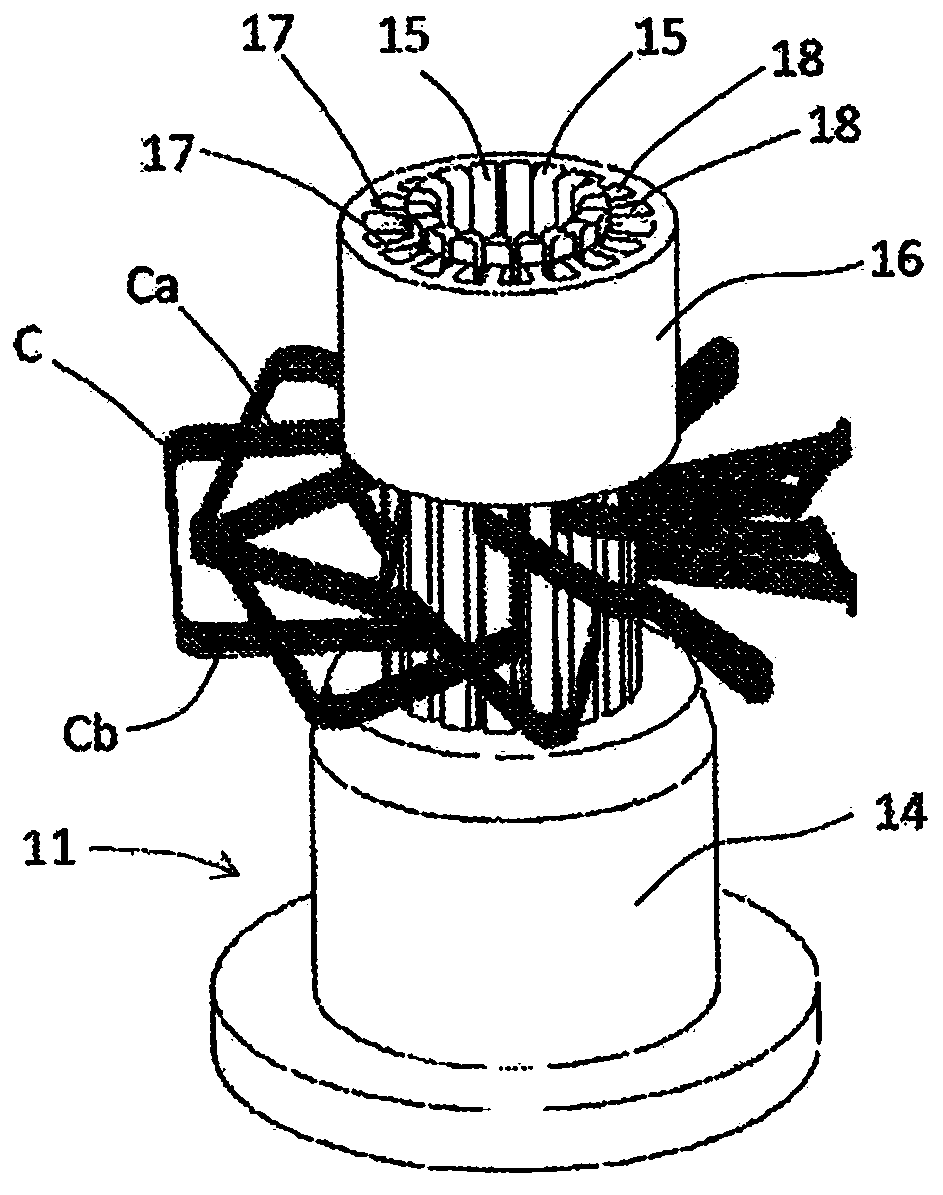

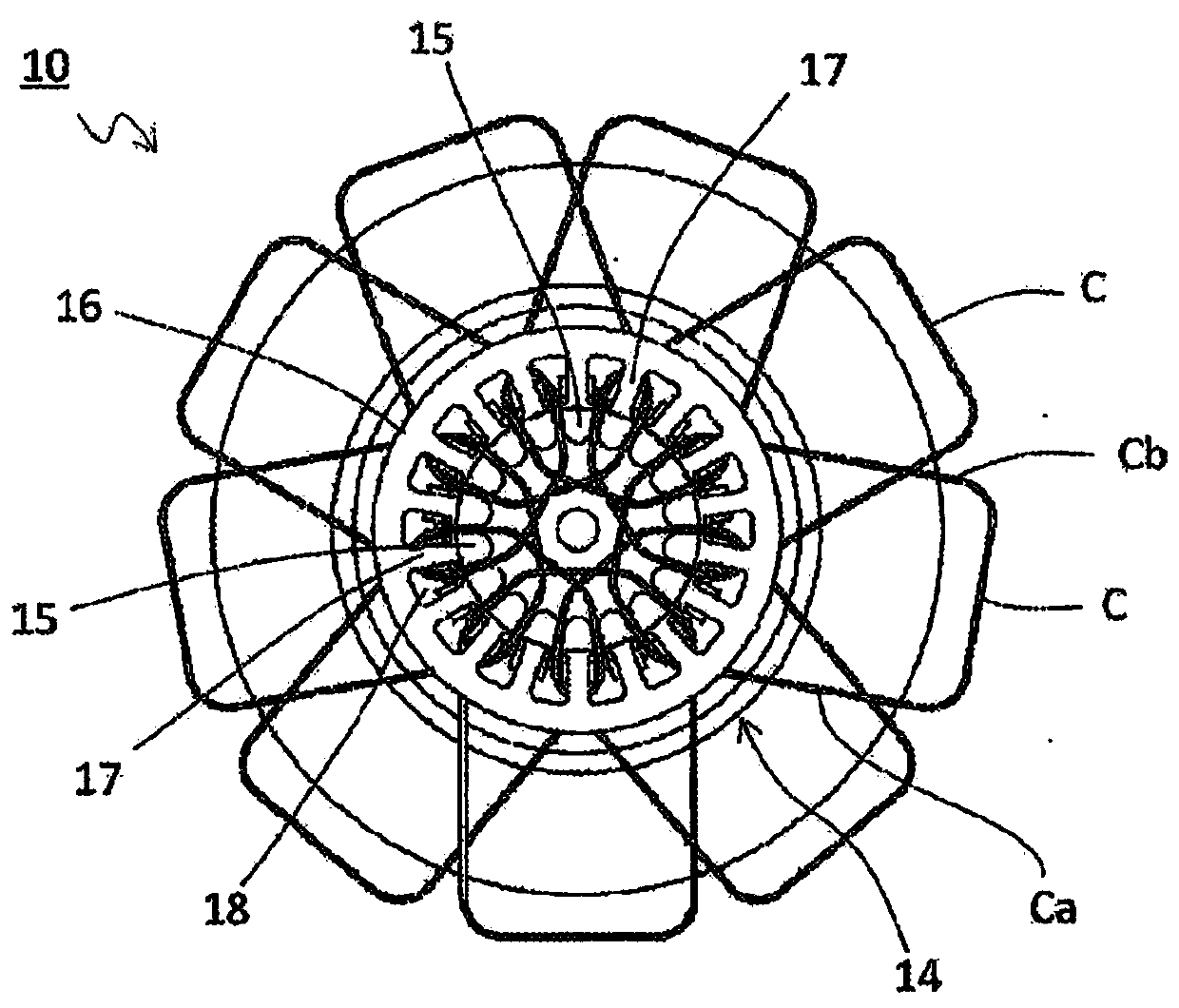

[0087] use Figure 1 to Figure 9 The illustrated coil insertion device of the present invention inserts the coils arranged in a helical shape overlapping each other on the coil insertion jig into the stator core. And, the insertion load at this time was measured, and the result was expressed as Figure 11 Curve C. In addition, in Comparative Example 1, Comparative Example 2, and Example 1, the specifications of the stator core and the coil are the same.

[0088] Such as Figure 11 As shown in the curve A of , when a conventional coil insertion device is used to insert a coil wound concentrically, the insertion load increases slowly and then decreases slowly. However, the peak value of the insertion load becomes very high.

[0089] Depend on Figure 11 It can be seen from the curve B in the figure that when using a conventional coil insertion device to insert coils stacked on top of each other in a helical shape, the insertion load increases significantly in the second hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com