Clip for attachment of floor carpet

An installation and carpet technology, applied in the direction of the device for tightening the carpet, the special position of the vehicle, the vehicle parts, etc., can solve the problems of the female part and the pad cap falling off, the pulling force of the floor pad, and the insertion force of the large shaft. , to reduce the insertion load, avoid misassembly, and achieve the effect of high pull-out force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

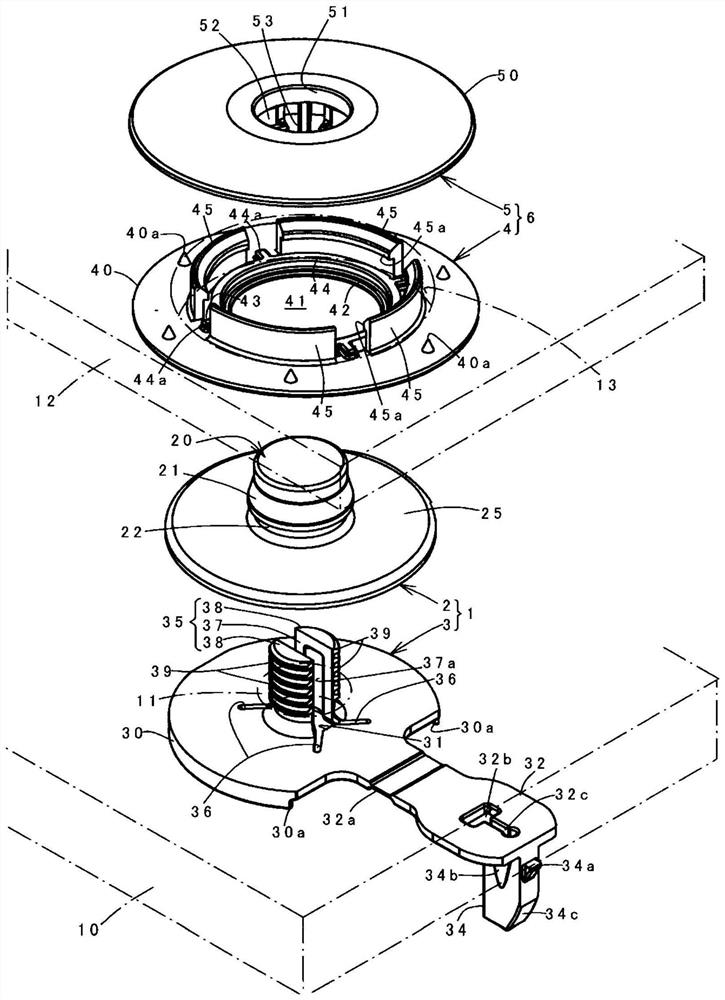

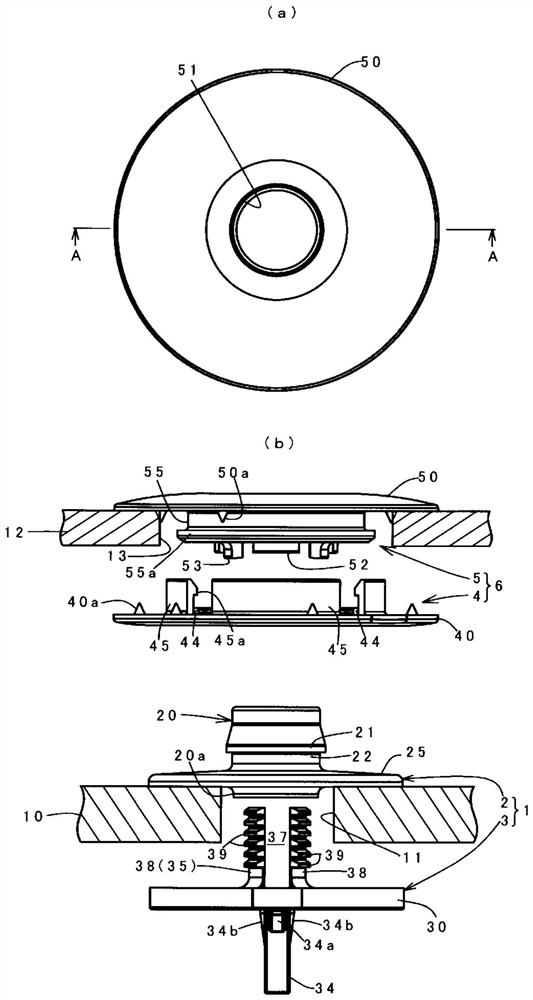

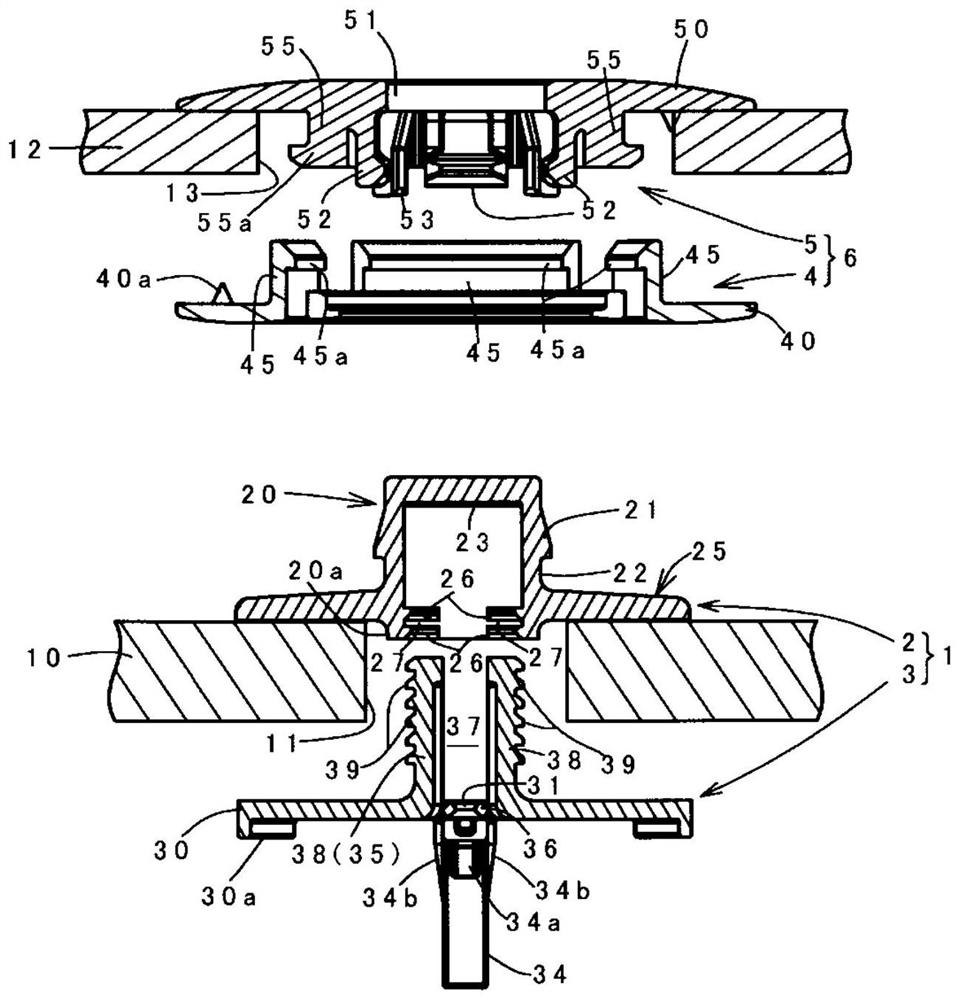

[0035] Hereinafter, the best mode of the present invention will be described with reference to the drawings. In this description, according to the structure of the clip for installing the floor carpet of the vehicle and its operating characteristics, the structure of the clamping body for installing the floor mat and its operating characteristics, and the relationship between the clip and the clamping body, that is, for relative The connection structure of the clip and the clamping body of the floor carpet mounting floor mat, and the order of the modification will be described in detail.

[0036] (The structure of the clip)

[0037] The clip 1 for attaching a floor carpet according to the embodiment includes: a female member 2 having a cylindrical portion 20 , an upper flange portion 25 protruding from the outer periphery of the cylindrical portion 20 , and an engaging member provided on the inner periphery of the cylindrical portion 20 . parts 26, 27; the male member 3 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com