waterproof plug

A waterproof plug and lip technology, which is applied in the field of waterproof plugs, can solve the problems of inability to stably ensure the waterproof performance of the replacement part, insufficient waterproof performance, etc., and achieve the effects of preventing cracks, ensuring waterproof performance, and reducing insertion load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

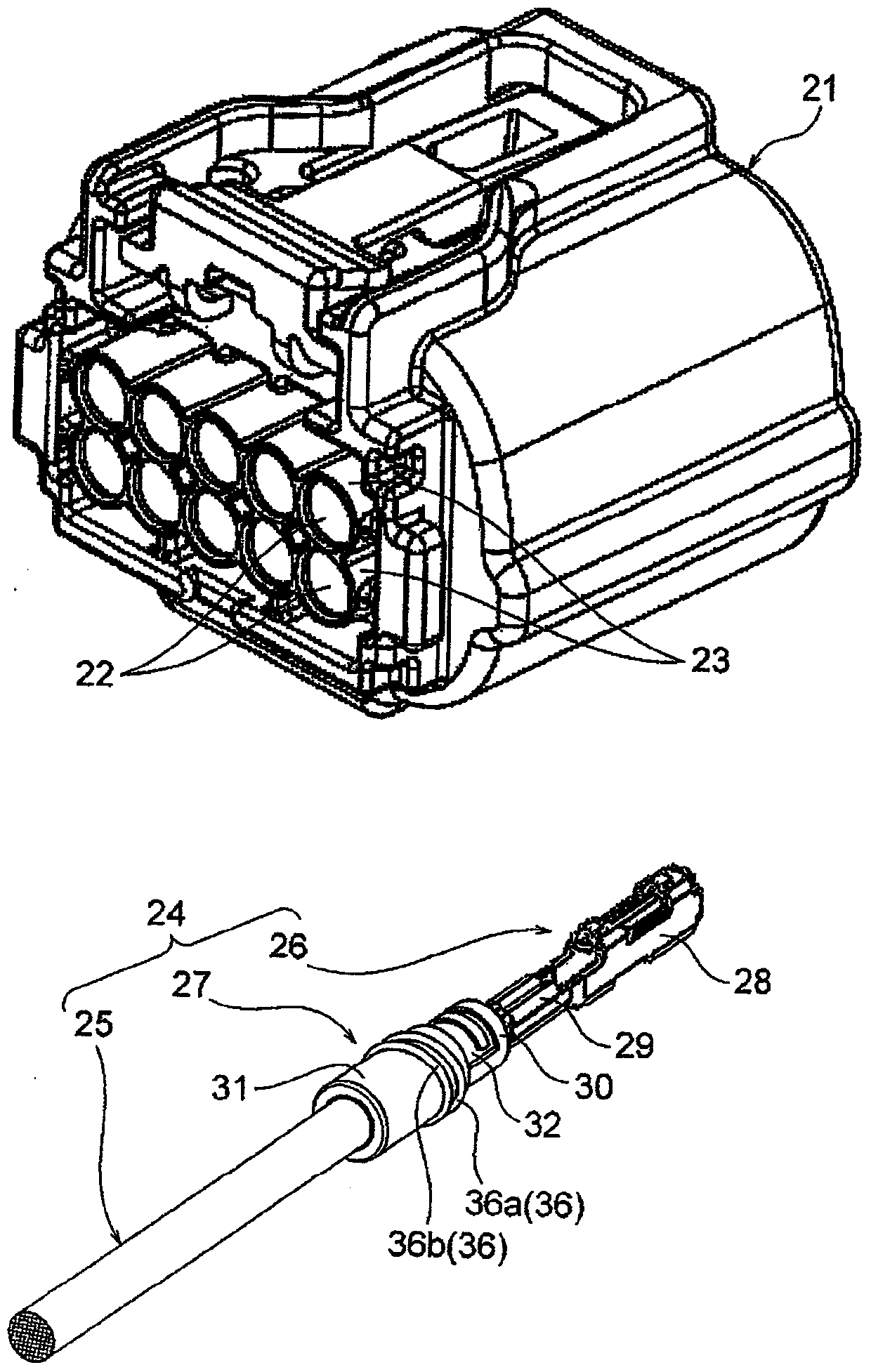

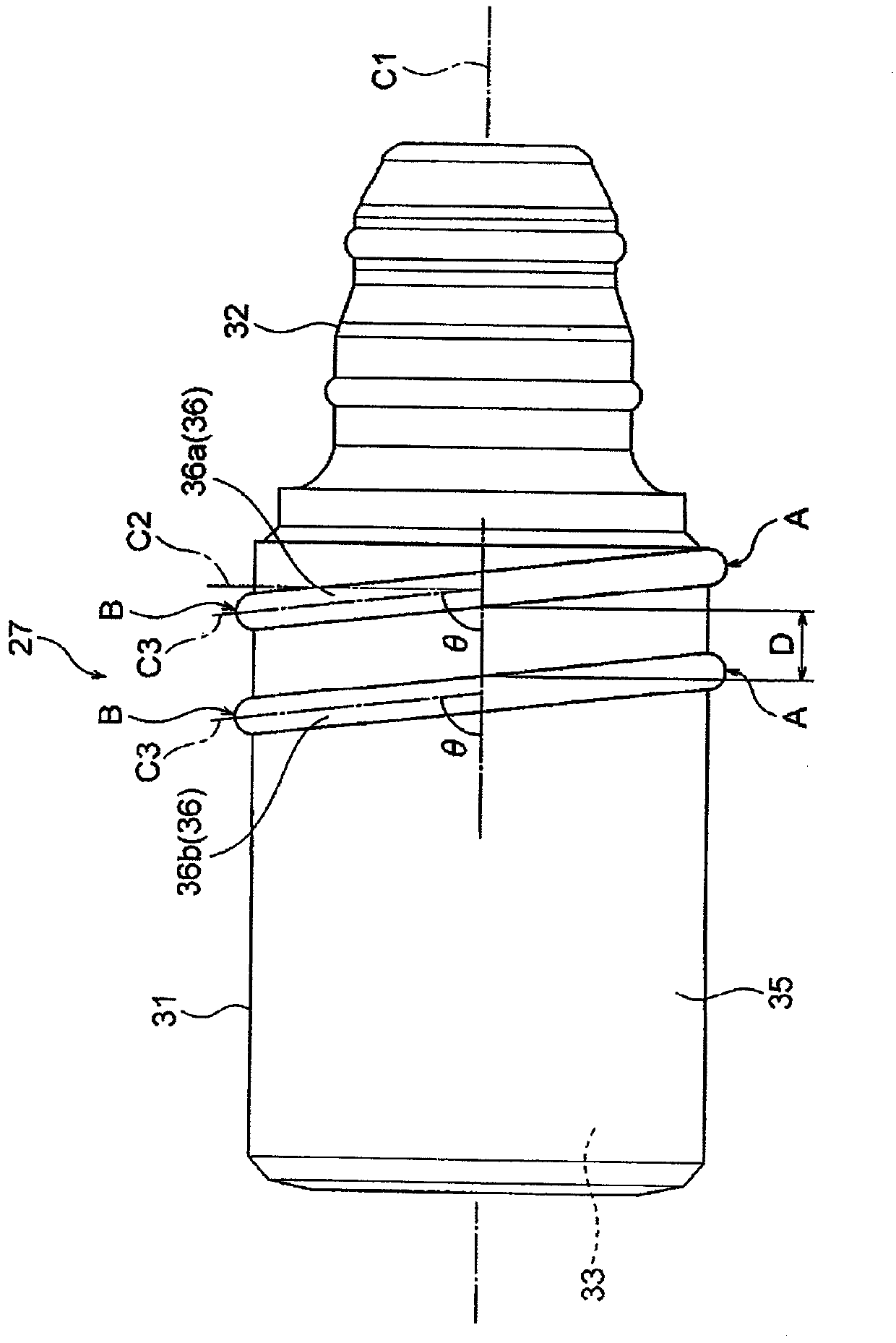

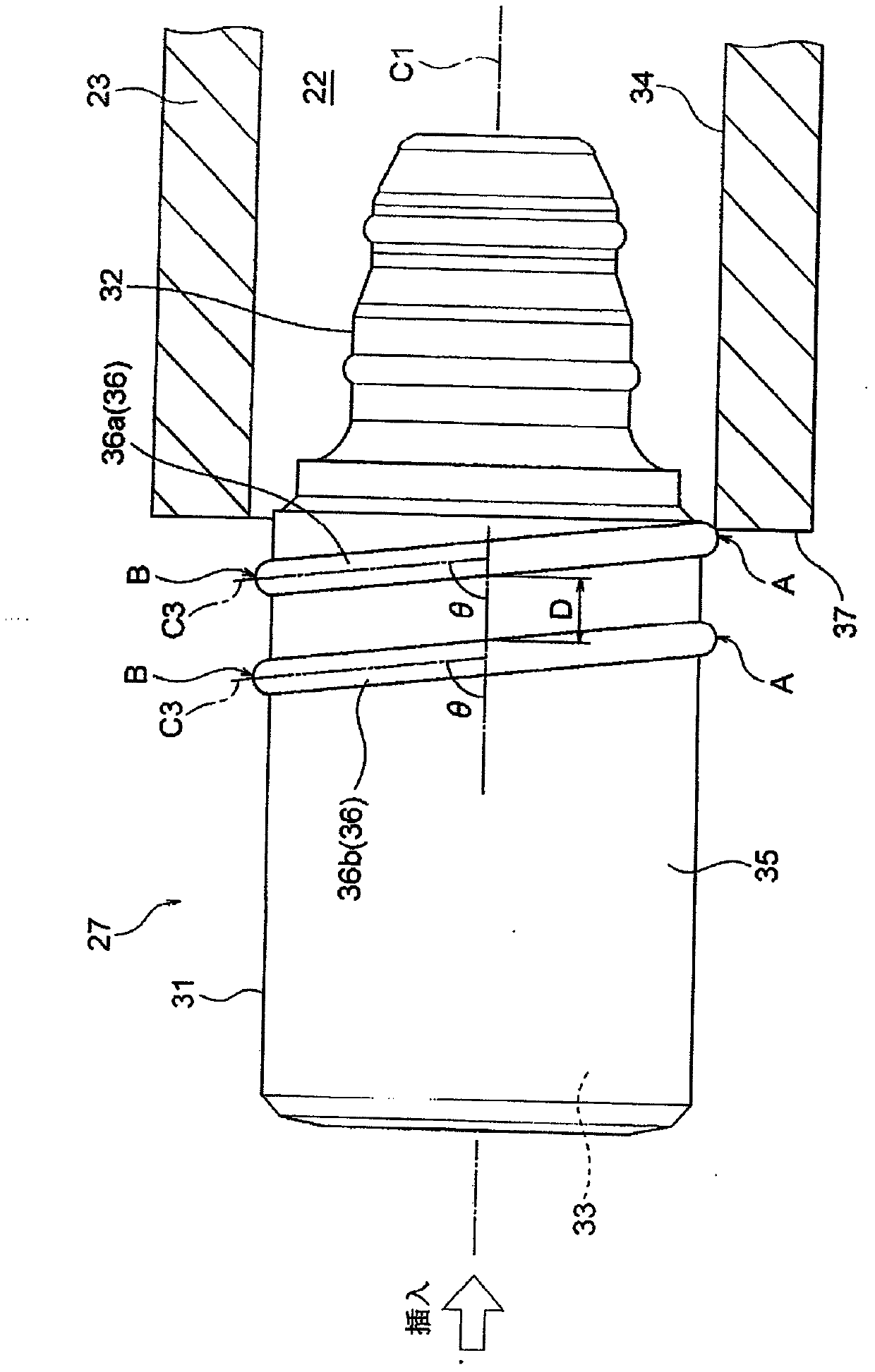

[0074] Hereinafter, Embodiment 1 will be described with reference to the drawings. figure 1 It is a perspective view showing an electric wire with a terminal to which the waterproof plug of the present invention is mounted, and a connector case serving as a storage destination for the electric wire with a terminal. in addition, figure 2 is the side view of the waterproof plug, image 3 is a schematic diagram showing the state when the waterproof plug is inserted into the terminal housing chamber, Figure 4 It is a front view of the waterproof plug schematically showing the first contact portion when the waterproof plug is inserted into the terminal accommodating chamber.

[0075]

[0076] exist figure 1 In , reference numeral 21 shows a connector housing of a connector used for electrical connection. The connector housing 21 is a molded product obtained by injection-molding an insulating resin material, and has a plurality of terminal accommodating chambers 22 . The ...

Embodiment 2

[0093] Hereinafter, Embodiment 2 will be described with reference to the drawings. Figure 5 It is a perspective view showing a terminal-provided electric wire equipped with a waterproof plug according to another example of the present invention, and a connector case serving as a storage destination of the terminal-provided electric wire. in addition, Image 6 is the side view of the waterproof plug, Figure 7 is a schematic diagram showing the state when the waterproof plug is inserted into the terminal housing chamber, Figure 8 It is a front view of the waterproof plug schematically showing the first contact portion when the waterproof plug is inserted into the terminal accommodating chamber. In addition, the same code|symbol is attached|subjected to the component which is basically the same as the said Example 1, and detailed description is abbreviate|omitted.

[0094]

[0095] exist Figure 5 Among them, the connector housing 21 has a plurality of terminal accommoda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com