A standardized movable scrap knife and trimming die structure

A technology of trimming molds and scrap knives, which is applied in the field of automobile stamping and forming, can solve the problems of plate pitting, iron filings, pit pockets, etc., and achieves the effect of strong practicability and avoiding trimming iron filings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

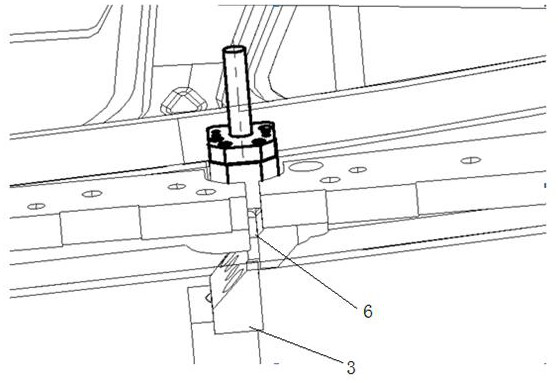

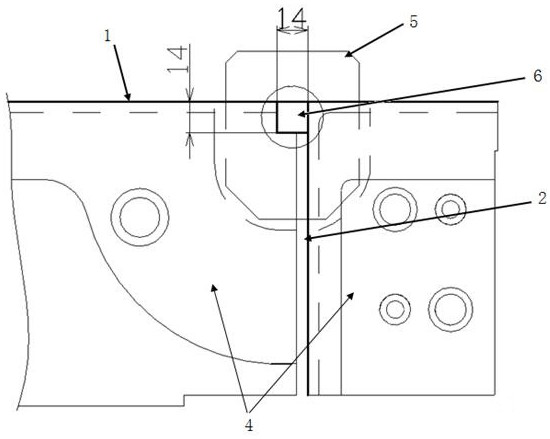

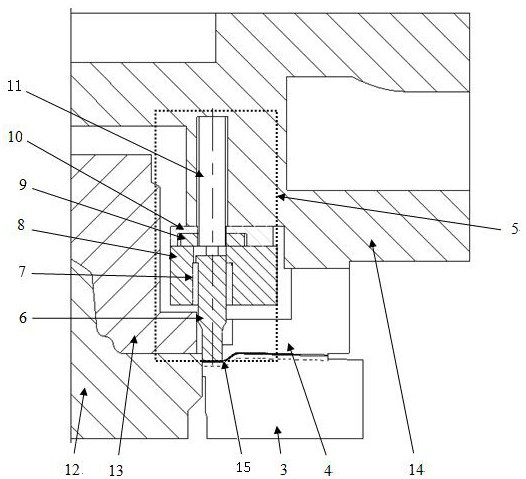

[0027] Such as figure 1 , 2 , shown in 3, the standardization movable scrap knife of the present invention is arranged on the trimming mold, and the trimming mold comprises a patrix 14 and a lower die seat, and the patrix 14 is provided with a patrix trimming knife 4, and the patrix trims The side knife 4 includes the main cutting edge 1 of the upper mold and the scrap cutting edge 2 of the upper mold. The lower mold base is provided with the scrap knife 3 of the lower mold. The key point is that the upper mold trimming knife 4 is also provided with a movable upper mold blade that can move up and down. 6 and the movable scrap knife assembly 5 that drives the movable upper mold edge 6; the movable scrap knife assembly 5 is embedded in the main edge 1 of the upper mold, so that the movable upper mold edge 6 is located on the main edge 1 of the upper mold and the waste cutting edge of the upper mold 2, and corresponds to the position of the waste knife 3 of the lower mold; the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com