Automobile seat skeleton structure

A car seat frame and frame technology, applied in the direction of seat frames, vehicle seats, vehicle parts, etc., can solve the problems of low backrest or seat frame frame strength, failure to meet safety design requirements, and non-compliance with lightweight, etc., to achieve The effect of overall strength improvement, structural improvement and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

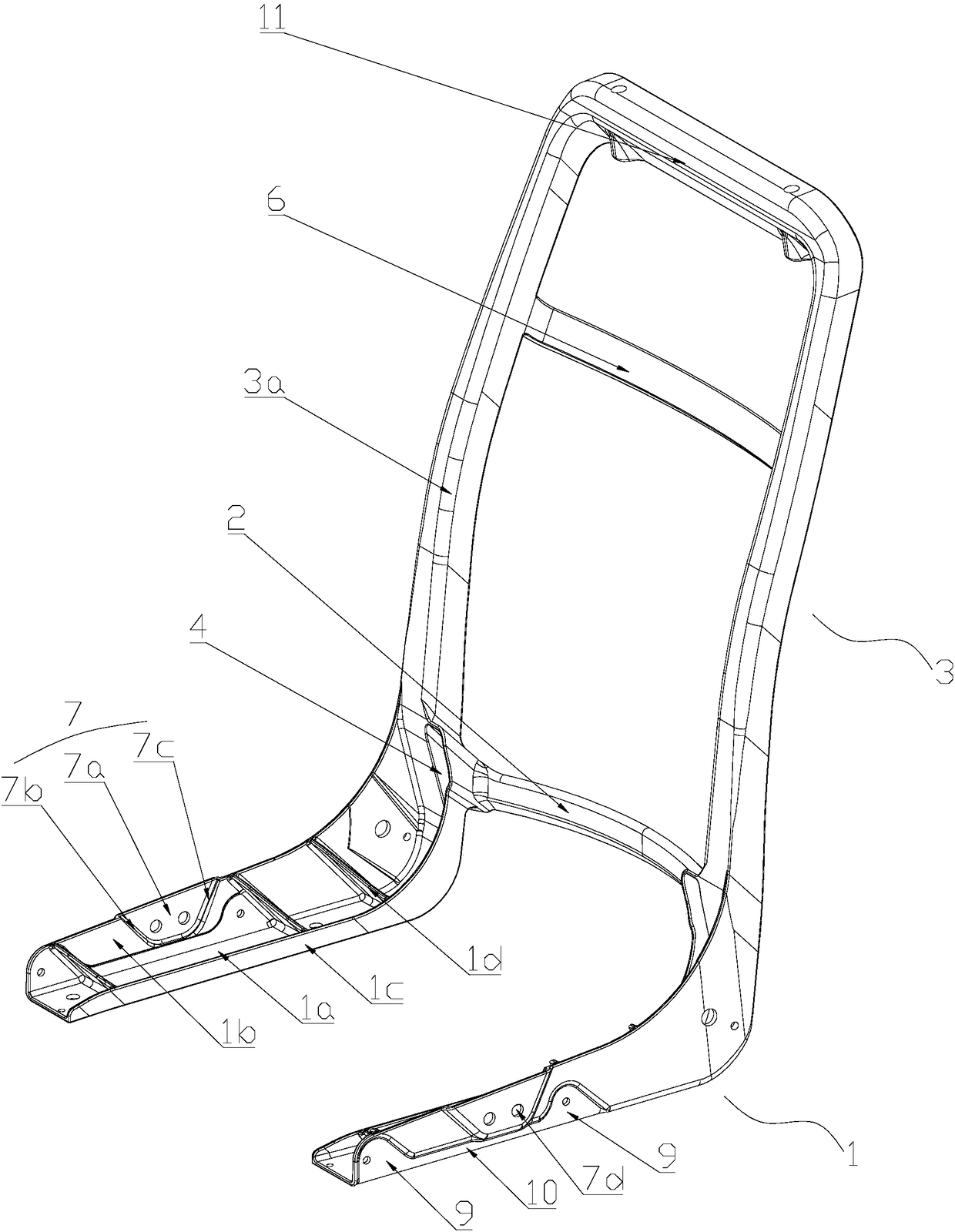

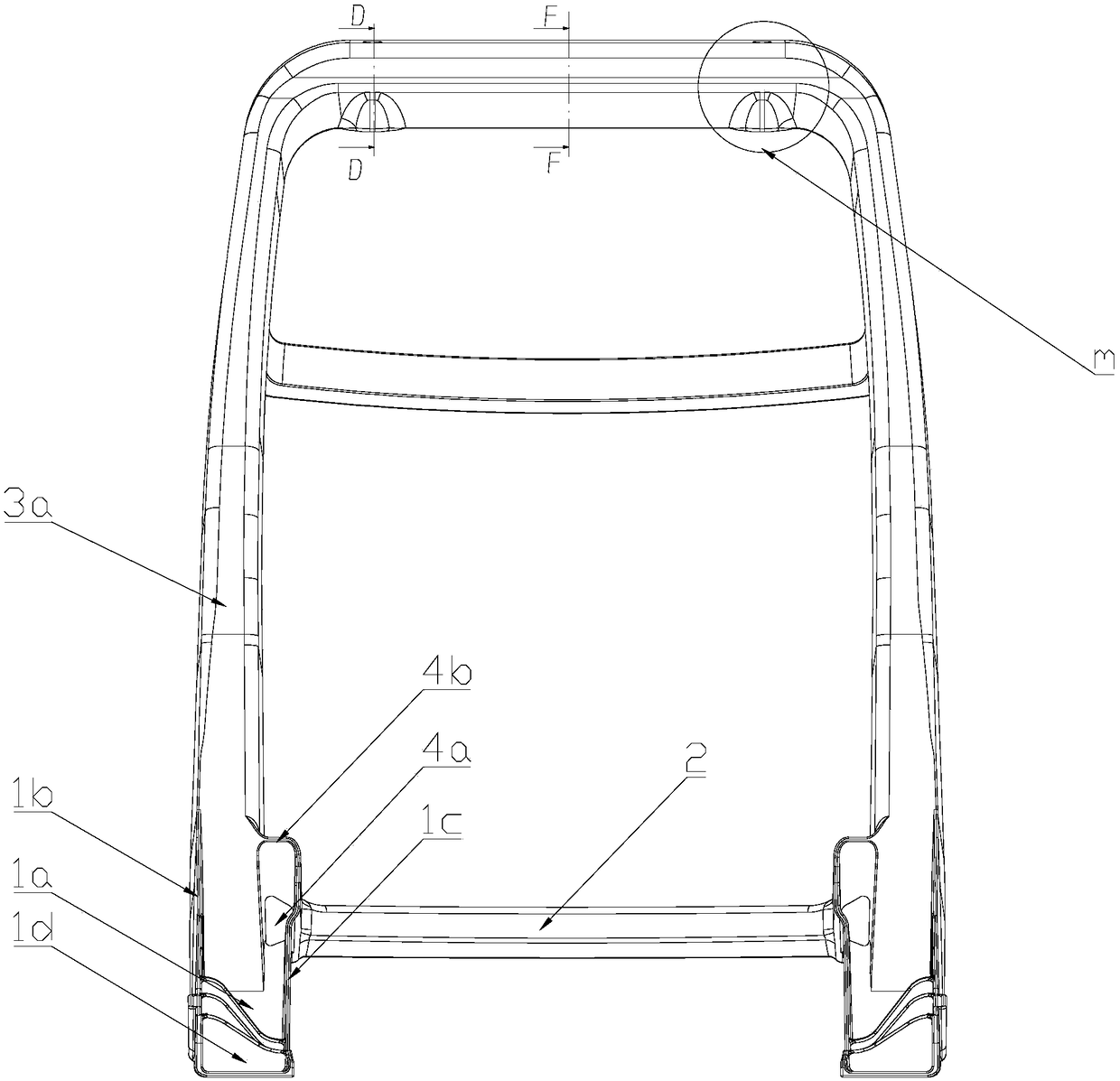

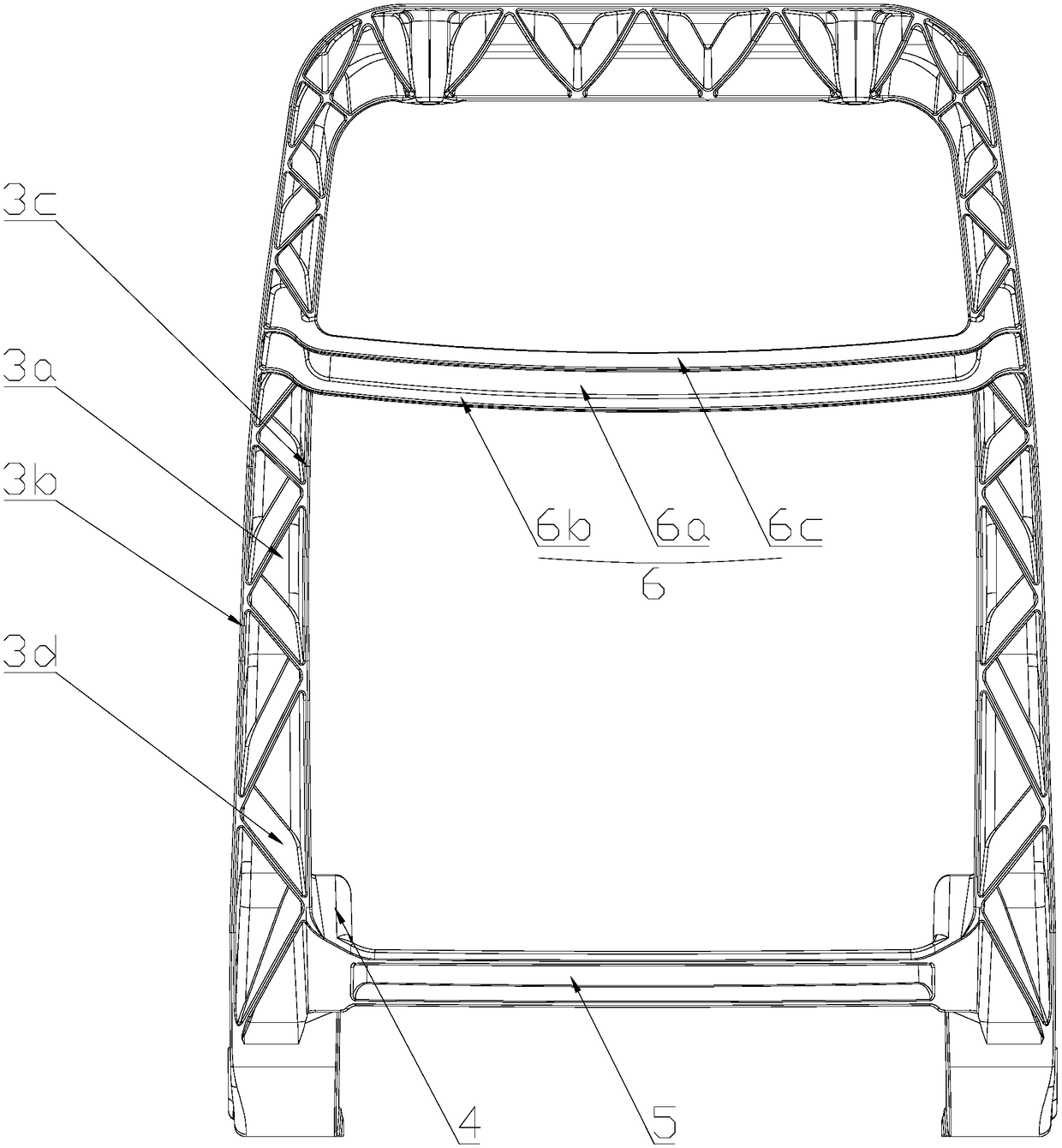

[0028] Such as Figure 1-3 As shown, a car seat frame structure includes a seat frame frame 1, a backrest frame 3 is connected to the rear of the seat frame frame 1, the seat frame frame 1 and the backrest frame 3 are integrally formed and both materials are Magnesium aluminum alloy.

[0029] The seat frame skeleton 1 includes two horizontally parallel seat frame side plate bottom plates 1a, the inner side and the outer side side of the seat frame side plate bottom plate 1a are respectively turned up to form the seat frame inner flange 1c and the seat frame The outer flange 1b, the heights of the seat frame outer flange 1b and the seat frame inner flange 1c gradually increase from front to rear respectively, and the height of any part of the seat frame outer flange 1b is greater than that of the corresponding position Describe the height of the flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com