Rotor test bench support position adjustment and bearing pre-tightening device

A technology for test benches and bearings, applied in the direction of shafts and bearings, bearing components, rigid supports of bearing components, etc., can solve problems such as difficulty in ensuring speed margin, threat to operator safety, and reduction of external force of supports, achieving cost savings Low, enhance the expansion, reduce the effect of supporting external force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

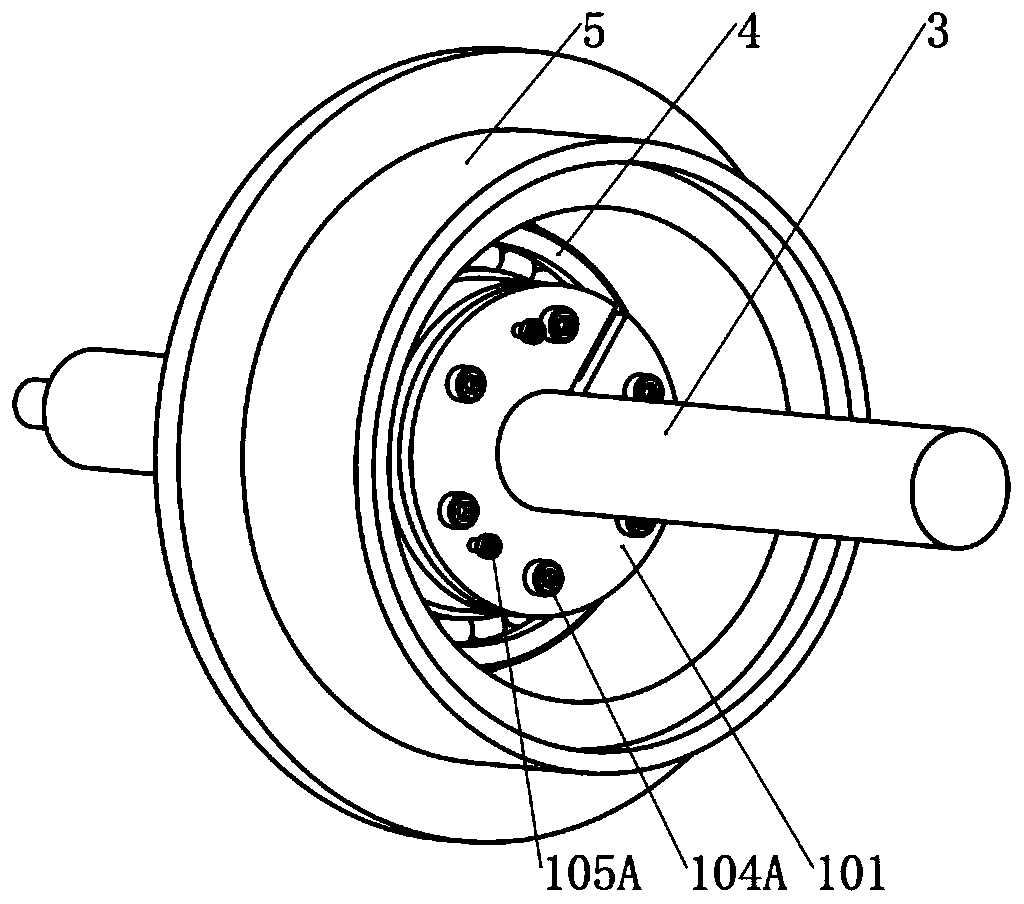

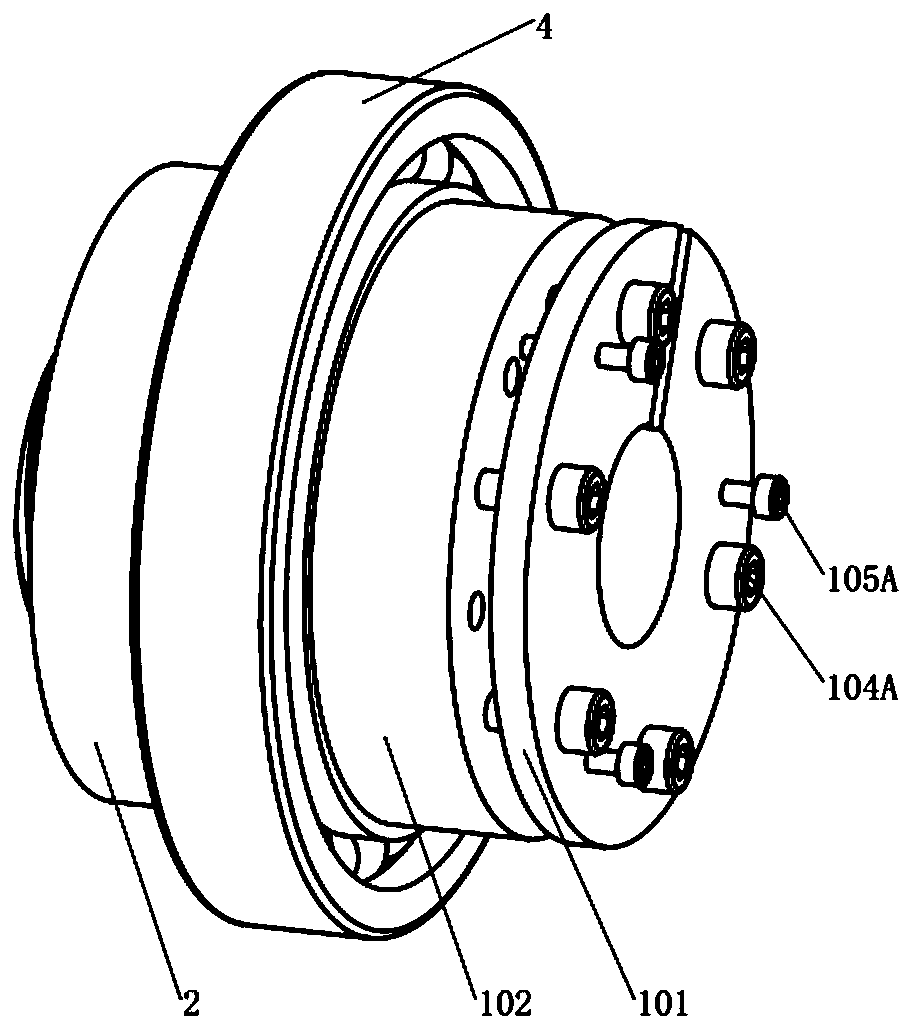

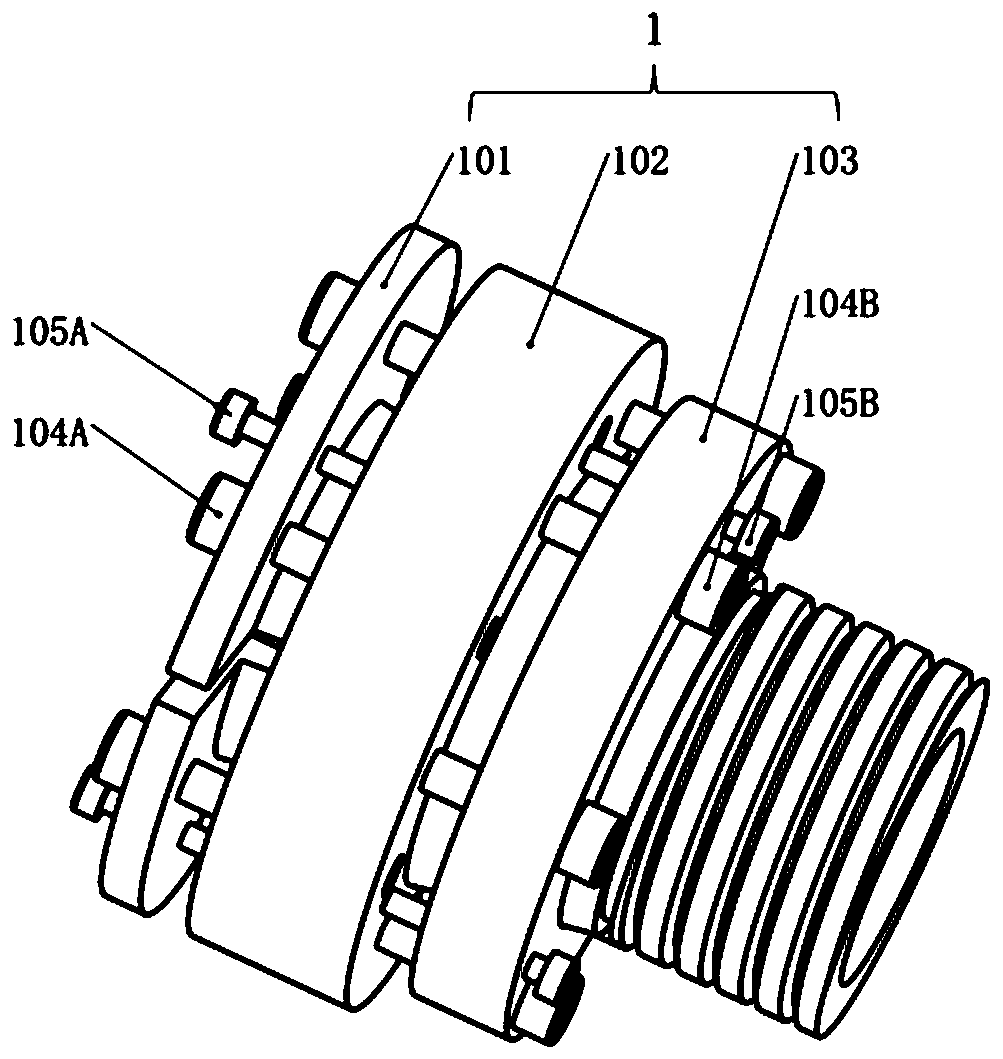

[0017] Such as Figure 1-7 As shown, a rotor test bench support adjustment and bearing pretensioning device includes a shaft 3, a support adjustment assembly 1 and a preload assembly 2, wherein the support adjustment assembly 1 includes a first coupling sleeve 101, a second coupling sleeve 102 and the third coupling sleeve 103, the pretensioning assembly 2 includes the pretensioning sleeve 201 and the spring 202; the shaft 3 is covered with the first coupling sleeve 101 and the second coupling sleeve 102, the first coupling sleeve 101 and the second coupling sleeve 102 are both It is disc-shaped and protrudes forward from the conical cylinder. The conical cylinder of the first coupling sleeve 101 is placed in the conical cylinder of the second coupling sleeve 102. The two cooperate with each other and the disc of the first coupling sleeve 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com