Scattering type smoke emission tear bomb

A tear gas, spraying technology, applied in the direction of warheads, ammunition, projectiles, etc., can solve the problems of easily injured personnel and our personnel, unstable ballistic performance, long smoking time, etc., to improve combat effectiveness and reduce kinetic energy damage. , the effect of fast smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

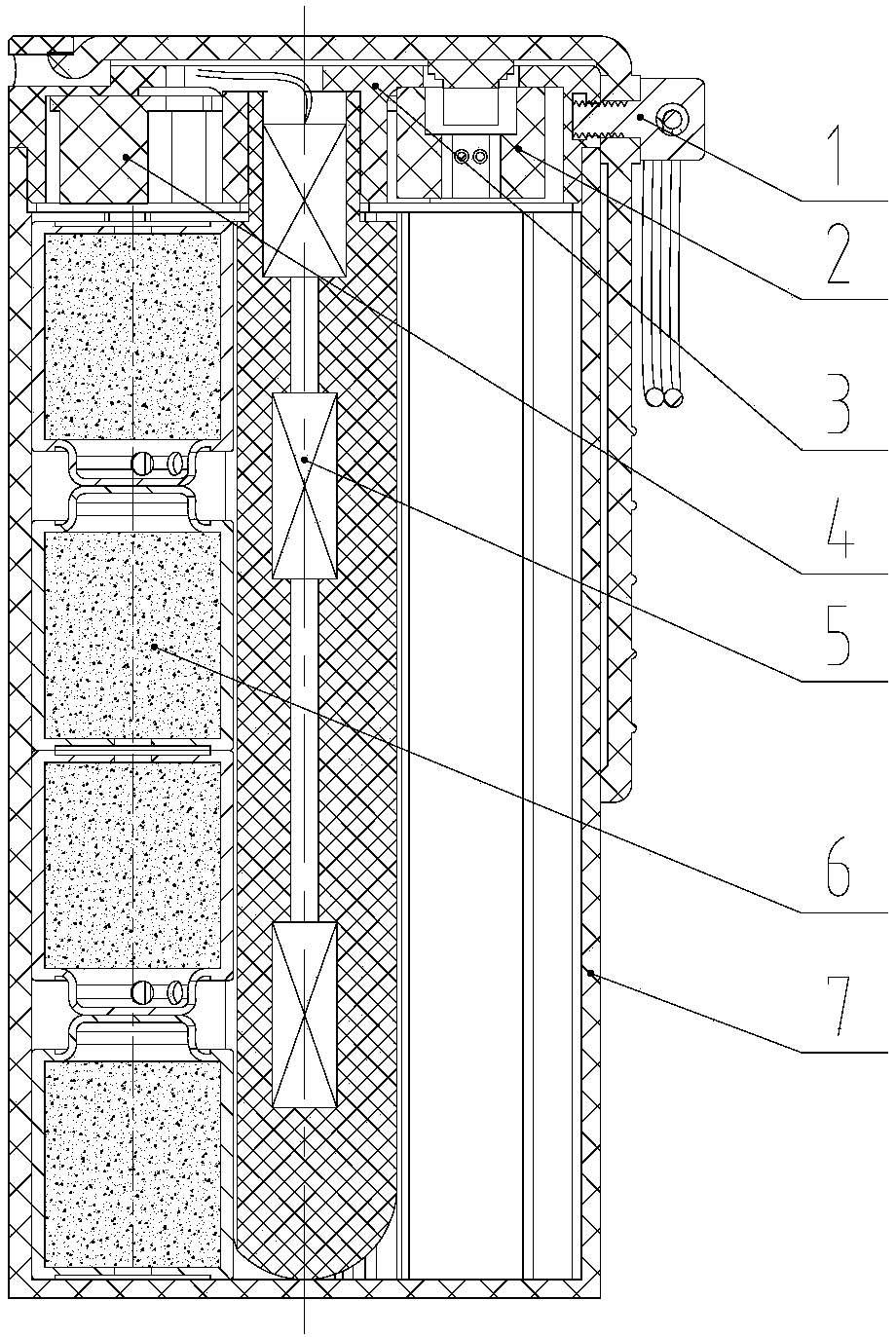

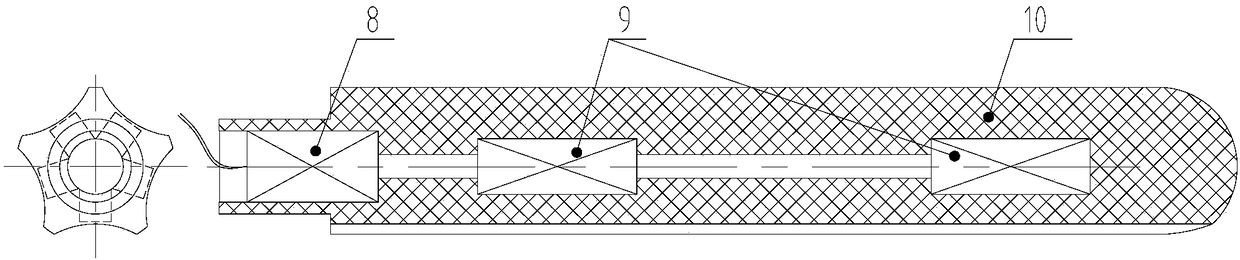

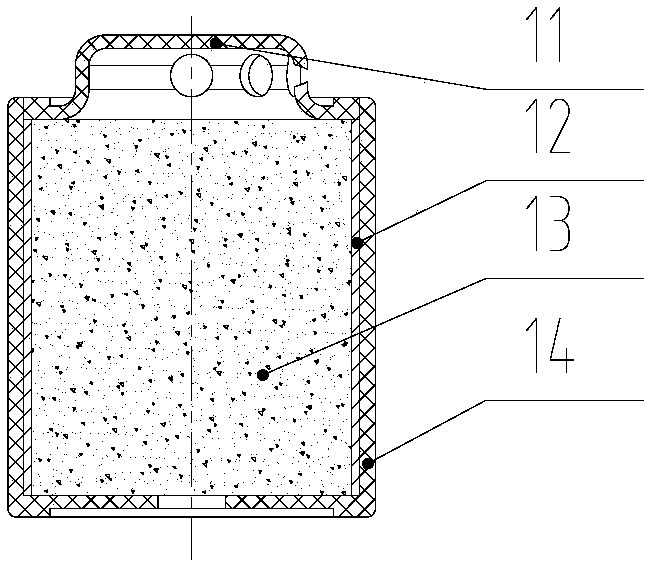

[0033] like figure 1 As shown, the dispensing type smoke tear gas bomb includes an outer casing 7, a smoke tear gas body 6, a pneumatic dispensing mechanism 5, an electrical socket assembly 2, an electronic control assembly 4, a cover plate 3 and a safety ring 1; the pneumatic dispensing The mechanism 5 is located in the inner center of the shell 7, and the smoke tear gas body 6 includes a plurality of them and is evenly distributed around the pneumatic dispensing mechanism 5; the electric socket assembly 2 and the electronic control assembly 4 are located at the upper end of the smoke tear gas body 6 The electronic control assembly 4 has the function of starting the pneumatic dispensing mechanism at a predetermined height or in the landing area; the cover plate 3 is located at the opening of the casing, and the smoke tear gas body 6, the pneumatic dispensing mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com