A semi-automatic tool measuring angle table device

A semi-automated, bench-mounted device technology, applied in the direction of angle/taper measurement, can solve the problems of low measurement efficiency and poor measurement accuracy, and achieve the effect of improved measurement efficiency, reasonable structure and close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

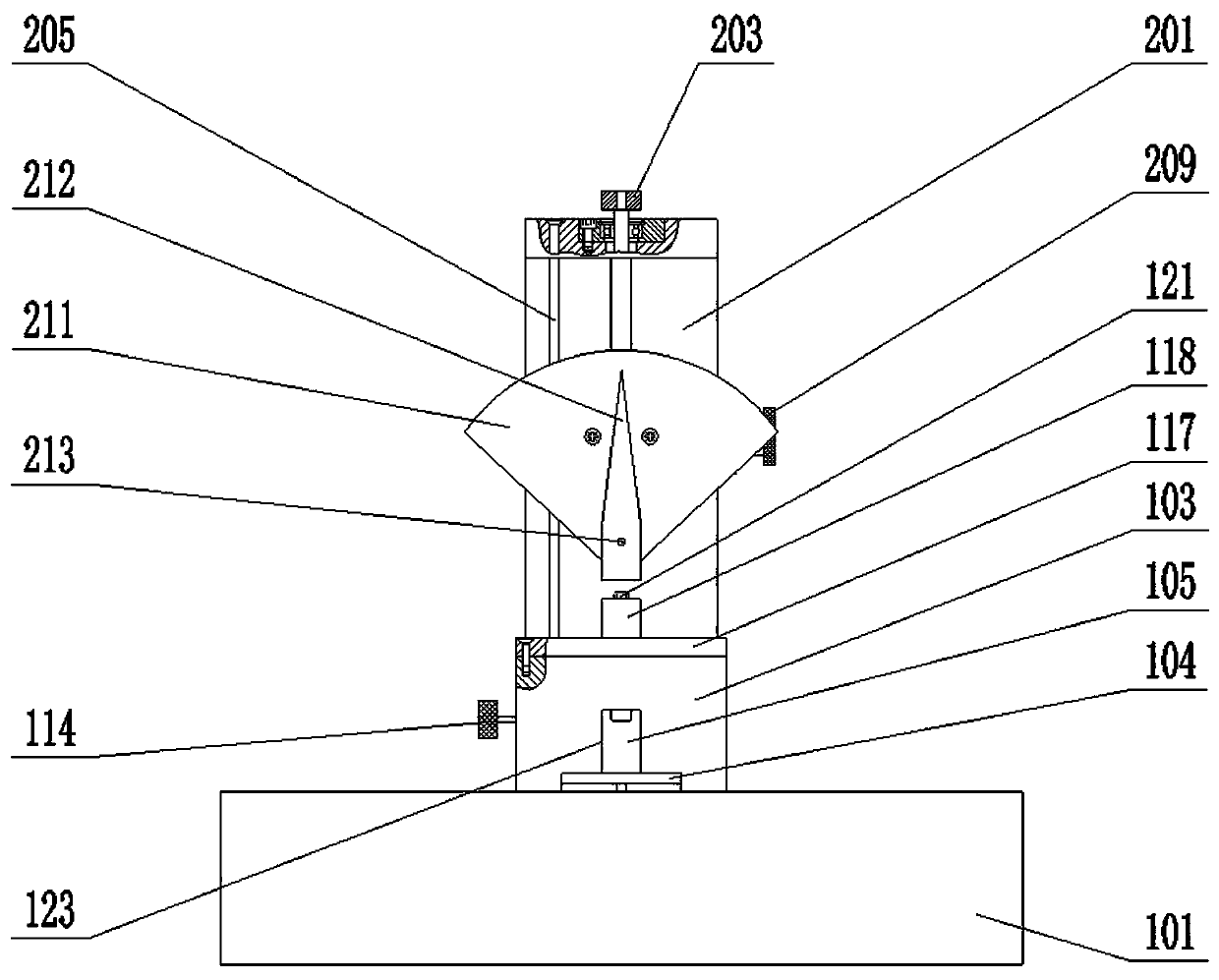

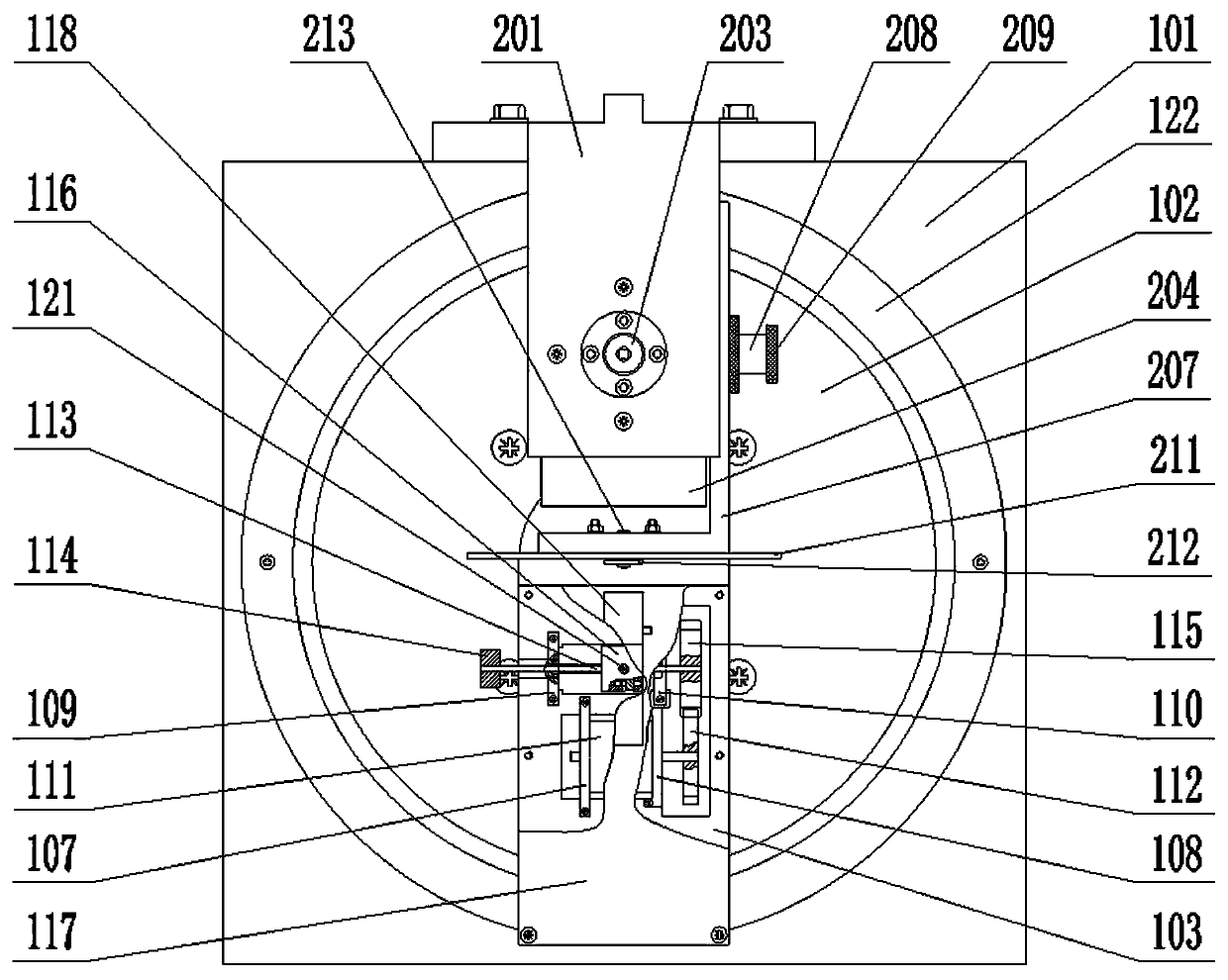

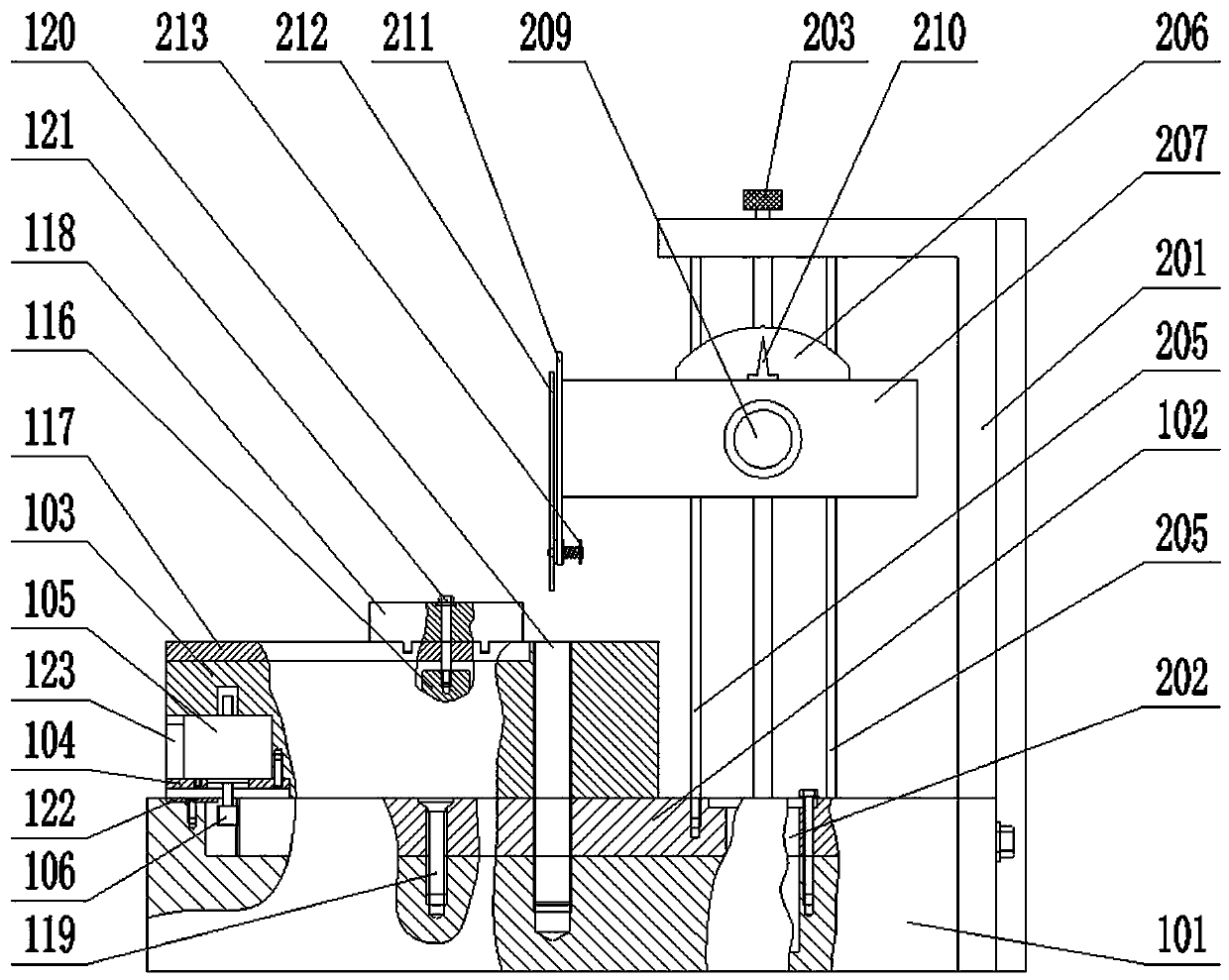

[0017] A semi-automatic tool measuring angle table device, including a support part and a measuring part;

[0018] Described support part comprises base platform 101, fixed gear 102, rotating platform 103, horizontal baffle plate 104, the 1st stepper motor 105, rolling gear 106, the 1st vertical baffle plate 107, the 2nd vertical baffle plate 108 , the III vertical baffle plate 109, the IV vertical baffle plate 110, the II stepping motor 111, driving gear 112, horizontal screw mandrel 113, the I knob 114, driven gear 115, slide seat 116, horizontal panel 117 , traverse platform 118, vertical screw 119, vertical screw rod 120, vertical bolt 121;

[0019] The upper table of the base platform 101 is provided with a disc-shaped concave cavity; the upper table of the base platform 101 is marked with a circular scale, and the circular scale surrounds the outside of the disc-shaped concave cavity; The front part of the bottom is provided with the first threaded concave hole; the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com