A central air-conditioning heat exchange tube leak detection device

A detection device and central air-conditioning technology, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, can solve the problems of reduced cooling efficiency and poor accuracy of the unit, and achieve manpower saving and detection precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

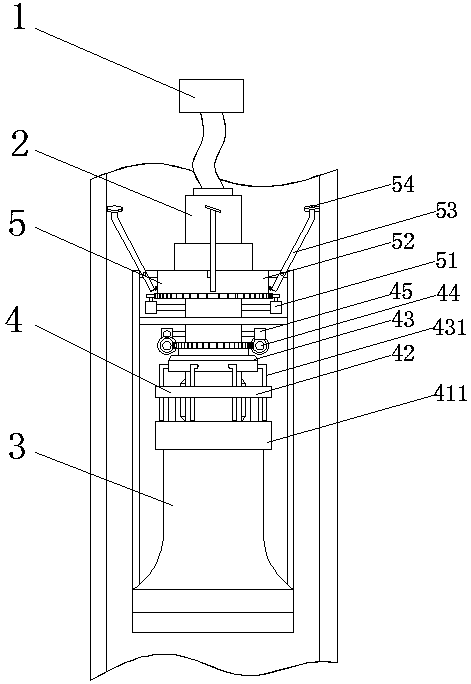

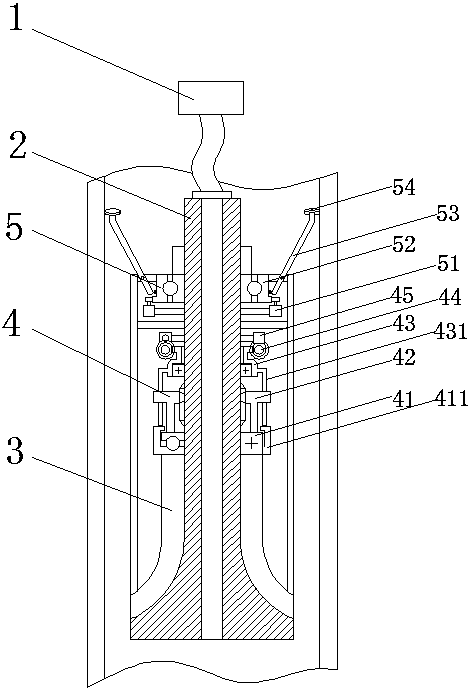

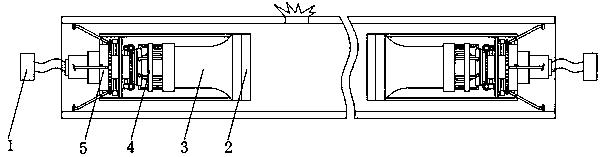

[0051] to combine figure 1 with figure 2 As shown, a central air-conditioning heat exchange tube leakage detection device disclosed in this embodiment includes: an industrial computer 1, a detection head 2, a plugging sleeve 3, a sleeve extrusion device 4 and a probe moving device 5. The interior of the detection head 2 is provided with an axial through hole, and the upper end of the through hole is connected to the industrial computer 1 through a vacuum tube. The lower end of the detection head 2 is provided with a cup-shaped structure with a gradually increasing outer diameter. 3 is socketed on the cup-shaped structure, the casing squeezing device 4 is socketed in the middle of the detection head 2, and the lower end of the casing squeezing device 4 is fixedly connected with the upper end of the blocking casing 3, so that The upper end of the detection head 2 is also sleeved with a detection head movement device 5; the plugging sleeve 3 is squeezed by the sleeve extrusion ...

specific Embodiment approach 2

[0056] This embodiment is based on the specific implementation mode 1, the difference is that the industrial computer 1 includes: a vacuum pump, a pressure gauge and a valve, the vacuum pump is connected to the vacuum tube, the pressure gauge is set on the vacuum tube, and the valve is set at the pressure On the vacuum tube between the gauge and the vacuum pump; after the vacuum pump forms a negative pressure environment, close the valve to maintain the pressure, and observe the pressure change through the pressure gauge to realize the vacuum pressure maintaining experiment.

specific Embodiment approach 3

[0058] This embodiment is based on the specific implementation mode 1, the difference is that the outer side of the detection head 2 is also provided with a casing, the plugging sleeve 3, the sleeve extrusion device 4 and the probe moving device 5 are all arranged in the casing; the casing provides protection to the internal components to prevent the device from being damaged during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com