Patents

Literature

31results about How to "With heat exchange function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

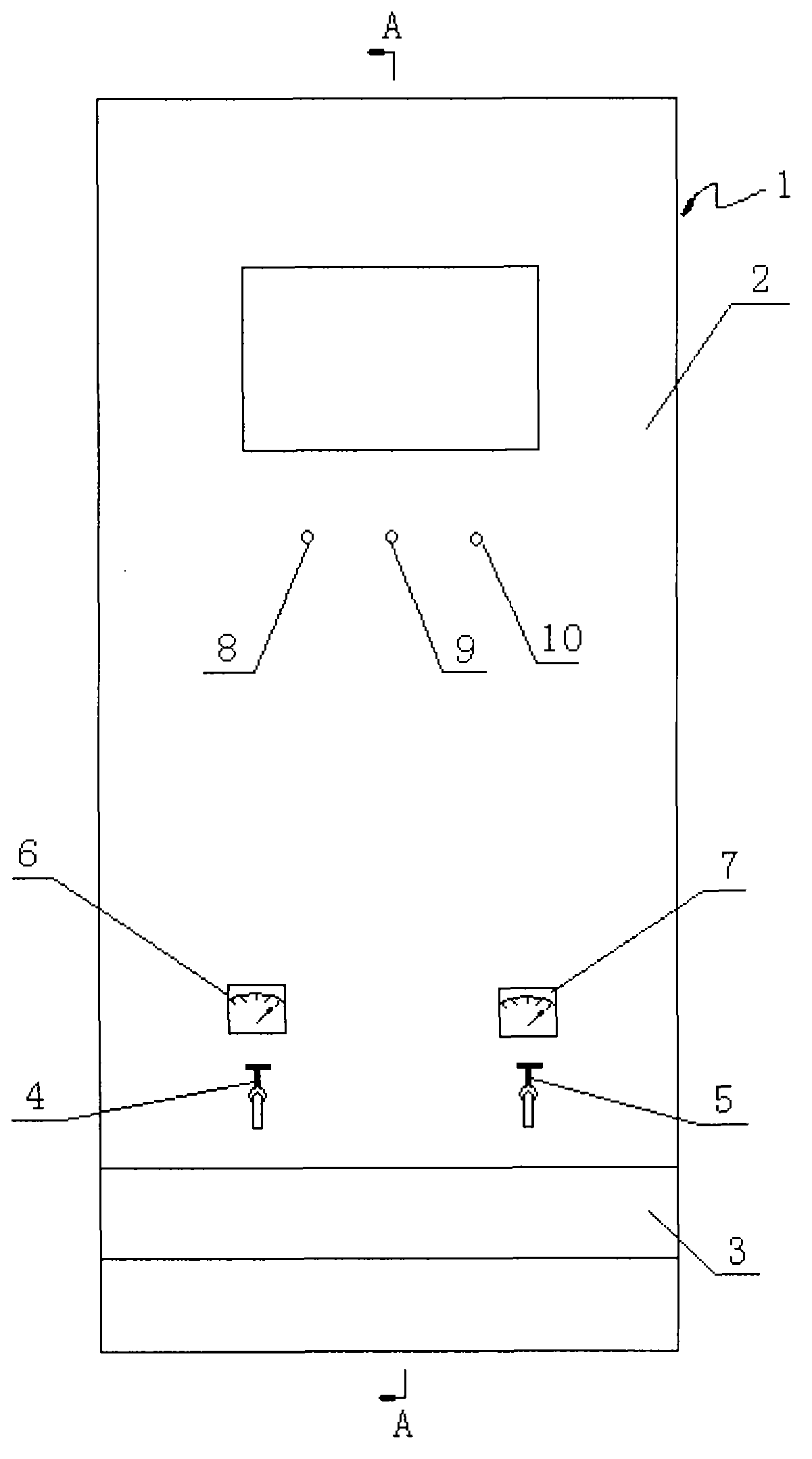

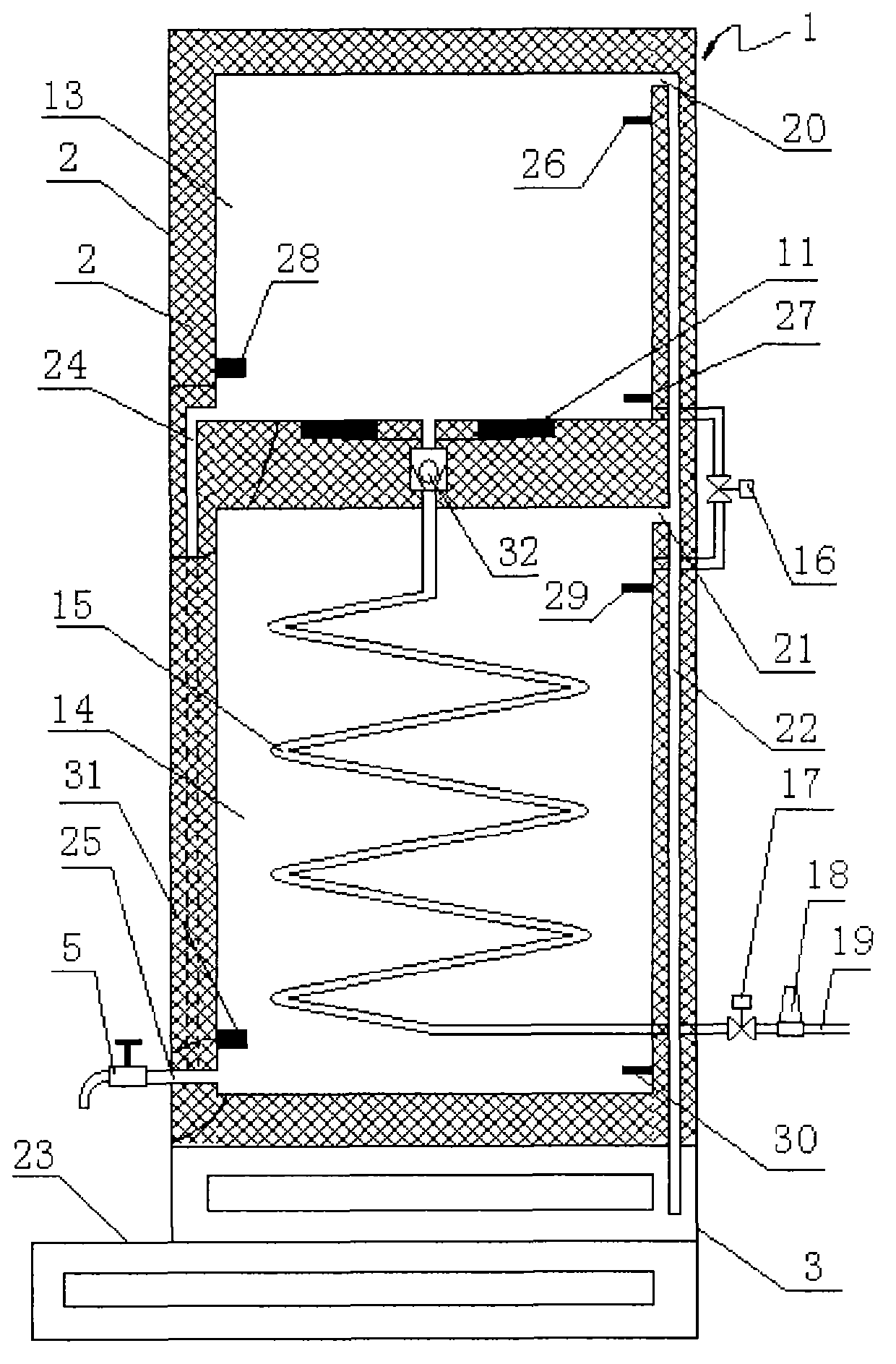

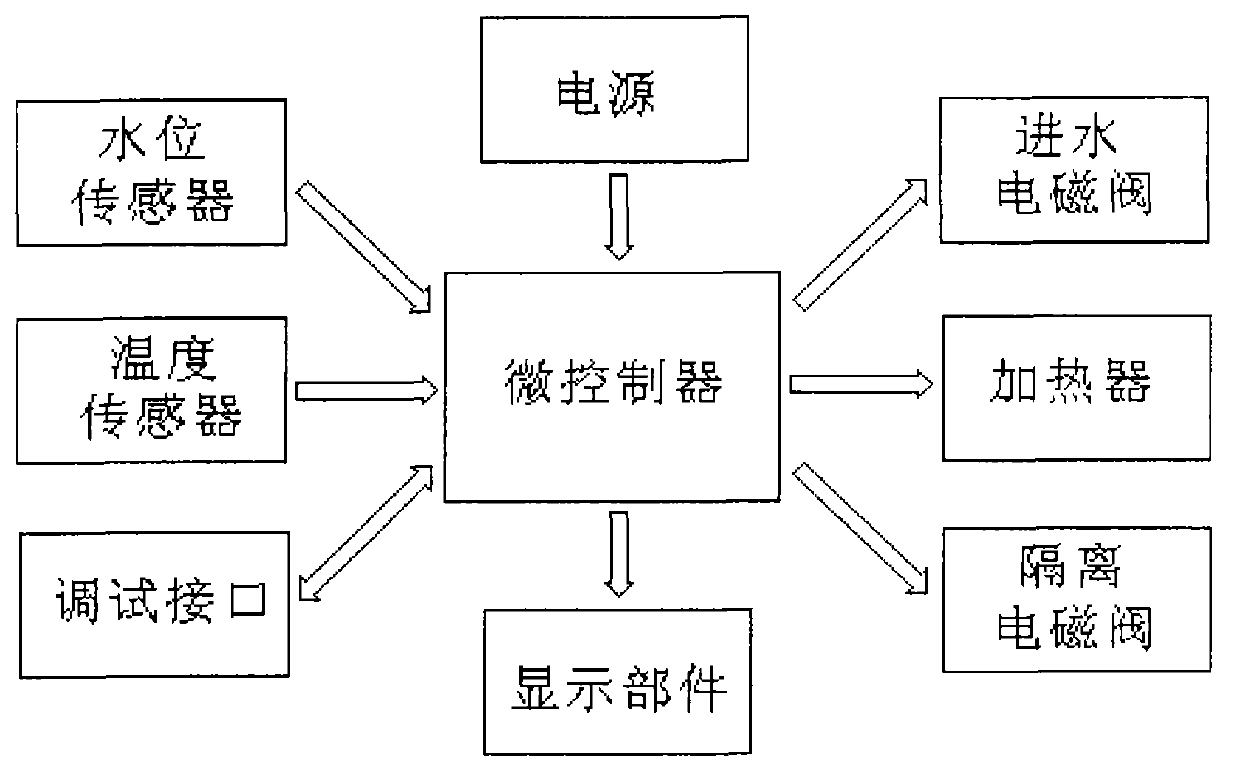

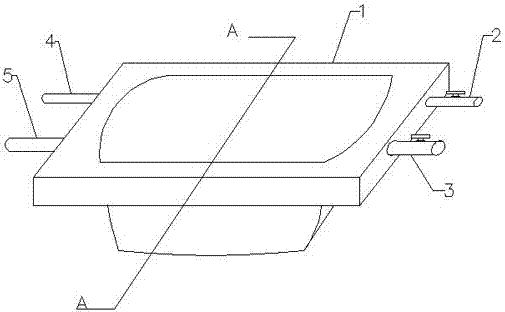

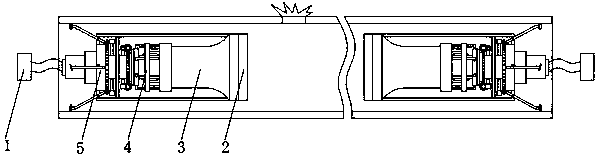

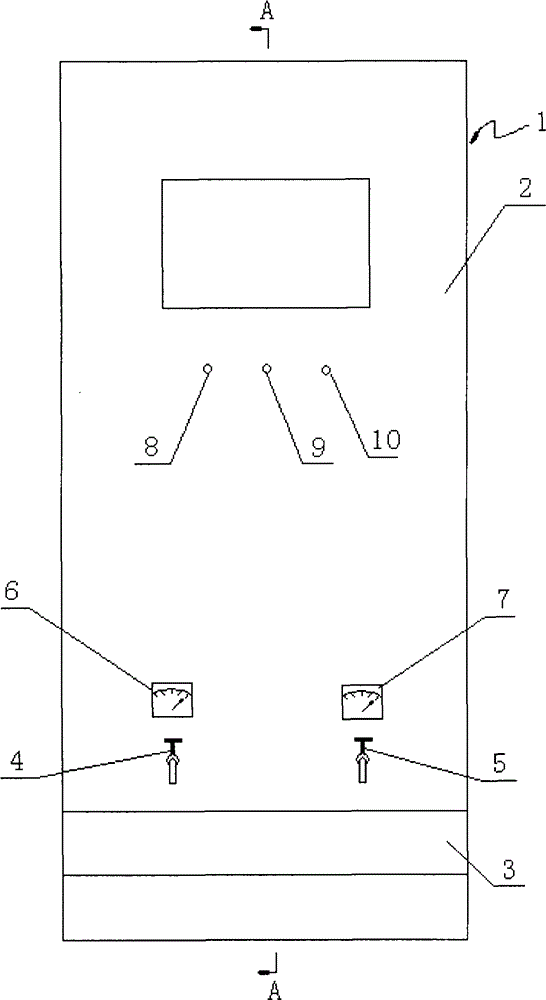

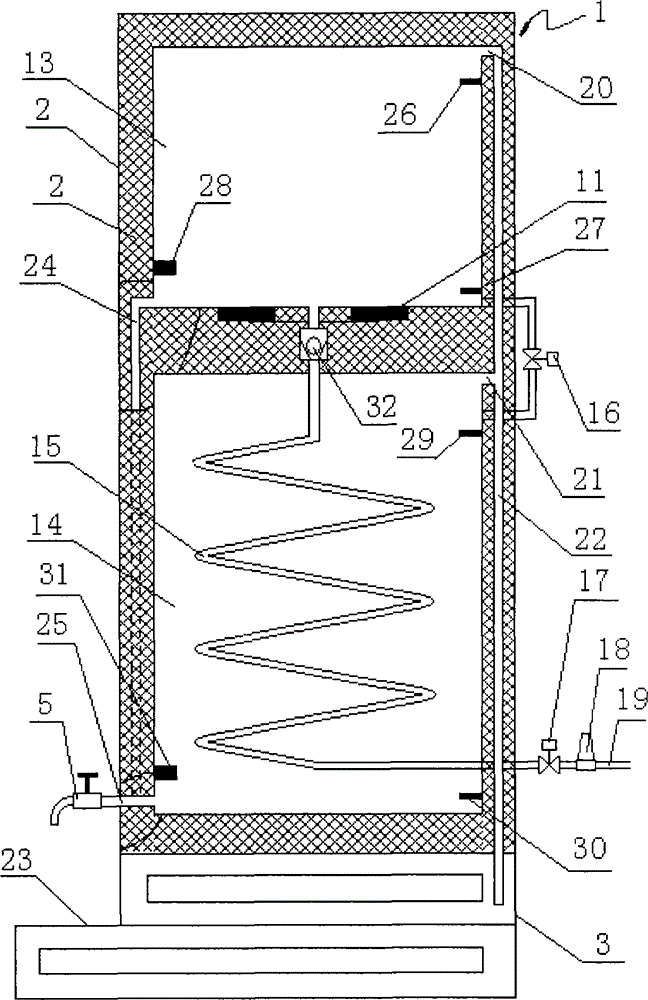

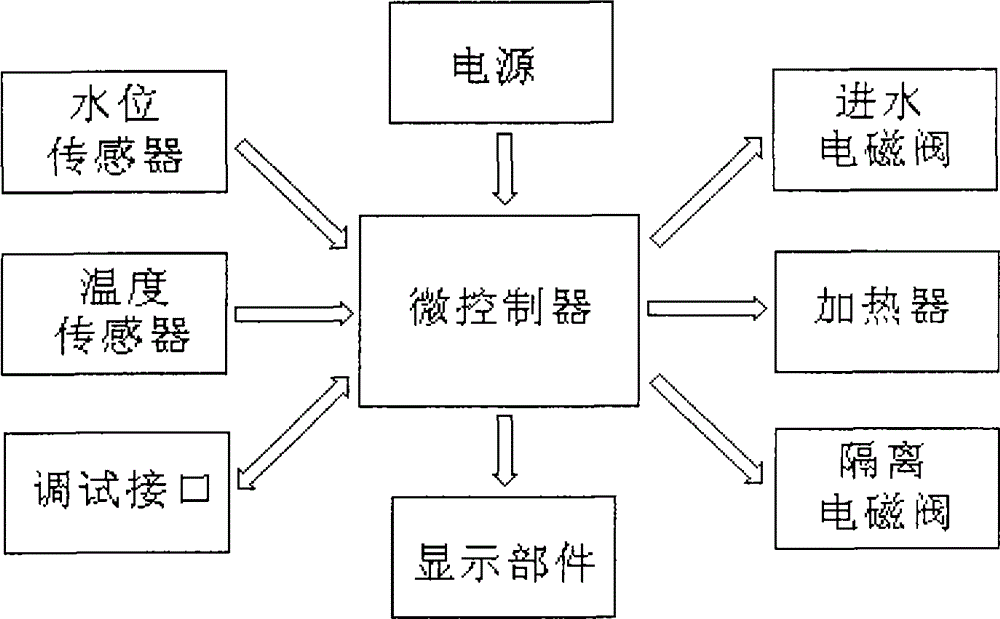

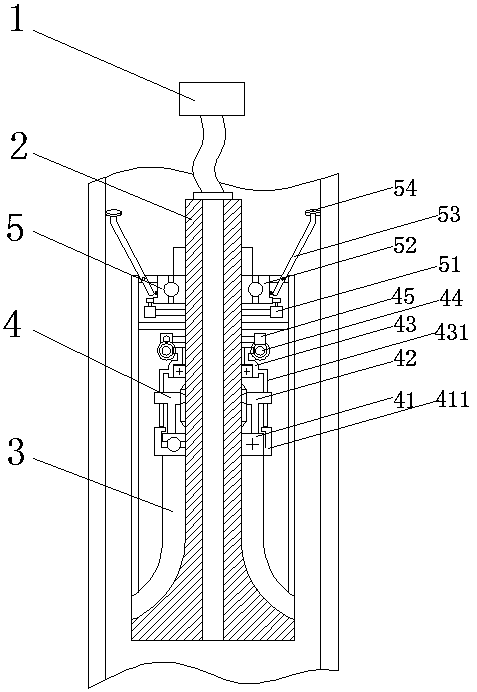

Open double-bucket water dispenser

InactiveCN103006062AWith heat exchange functionGood energy saving effectBeverage vesselsMicrocontrollerPhysical health

Disclosed is an open double-bucket water dispenser. A hot water bucket and a warm water bucket are arranged in a box of the water dispenser. The hot water bucket is located above the warm water bucket, and capacity of the hot water bucket is smaller than that of the warm water bucket. The hot water bucket and the warm water bucket are communicated with a hot water tap and a warm water tap which are arranged on the front side of the box respectively. A heat exchanging pipe is arranged inside the warm water bucket, the lower end of the heat exchanging pipe is led out from the lower portion of the warm water bucket to be communicated with a water inlet pipe through a water inlet solenoid valve, and the upper end of the heat exchanging pipe penetrates through the warm water bucket to be communicated with a cavity of the hot water bucket through a one-way valve. An isolating solenoid valve is arranged between the hot water bucket and the warm water bucket. A microcontroller controls on and off of the solenoid valve and on and off of a heater according to signals detected by a water level sensor and a temperature sensor. Energy saving of the water dispenser can be well achieved, hot water and warm water can be provided at the same time, unboiled water and boiled water and reboiled water are also avoided, and physical health of a long-term user is benefited.

Owner:王森

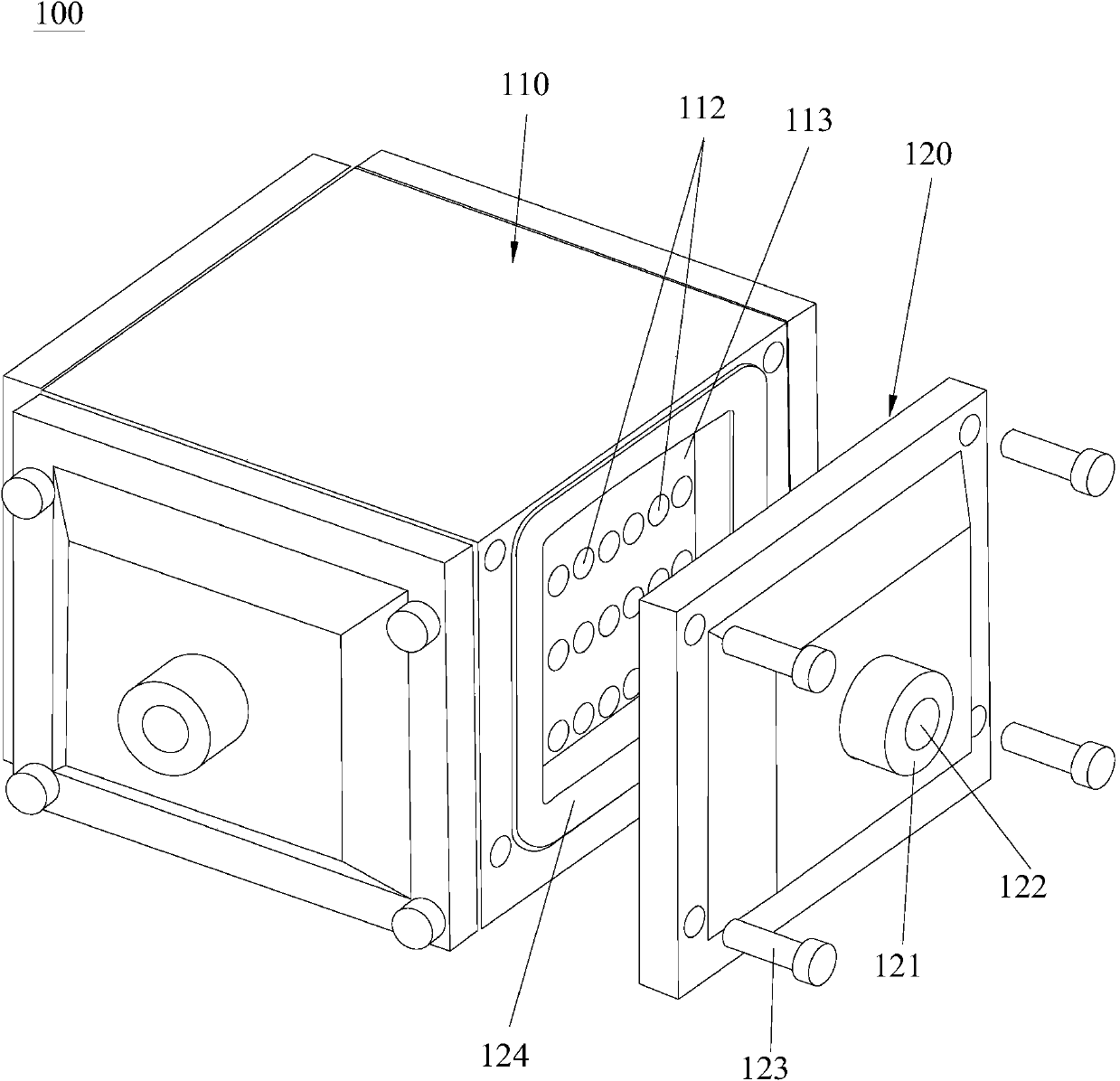

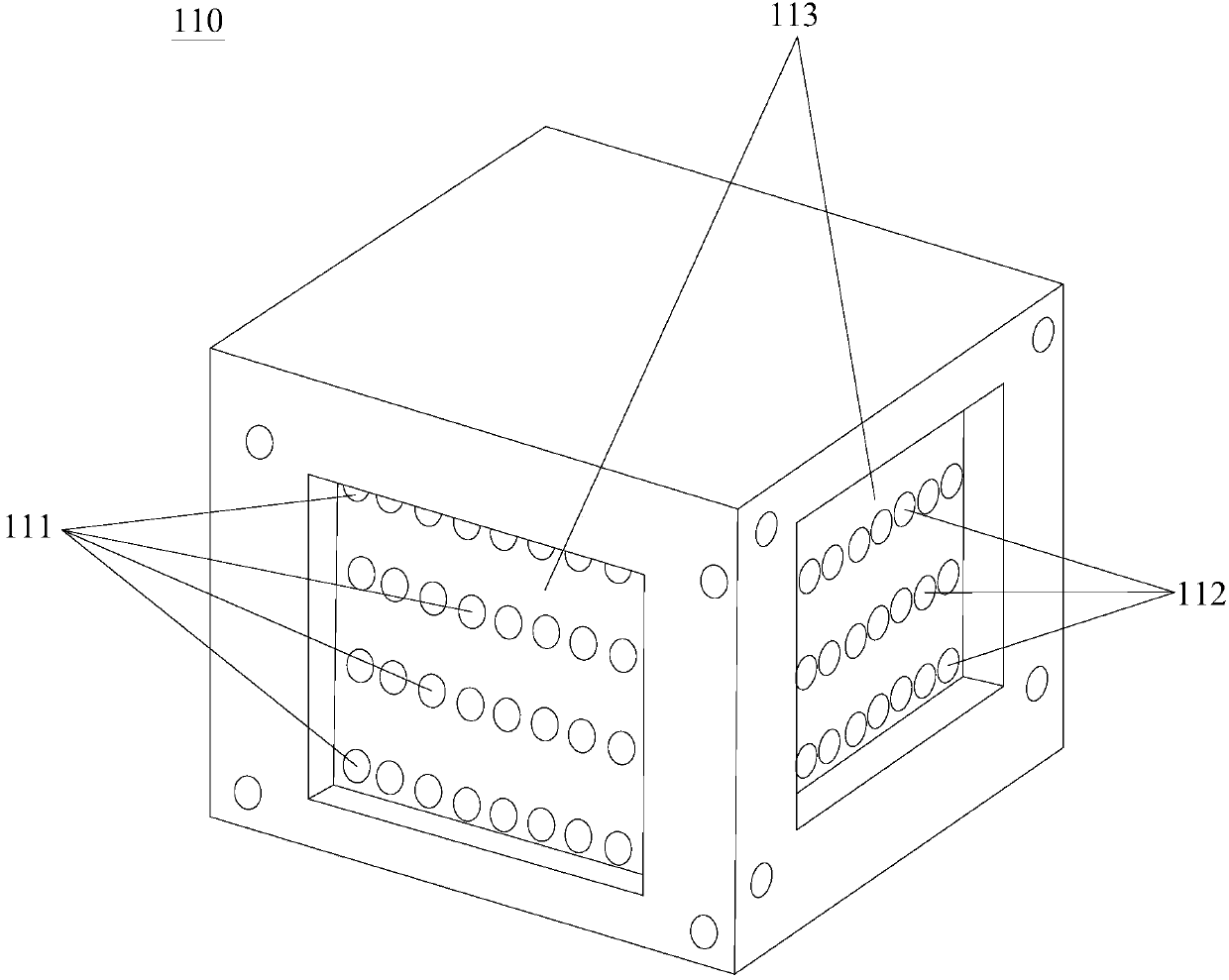

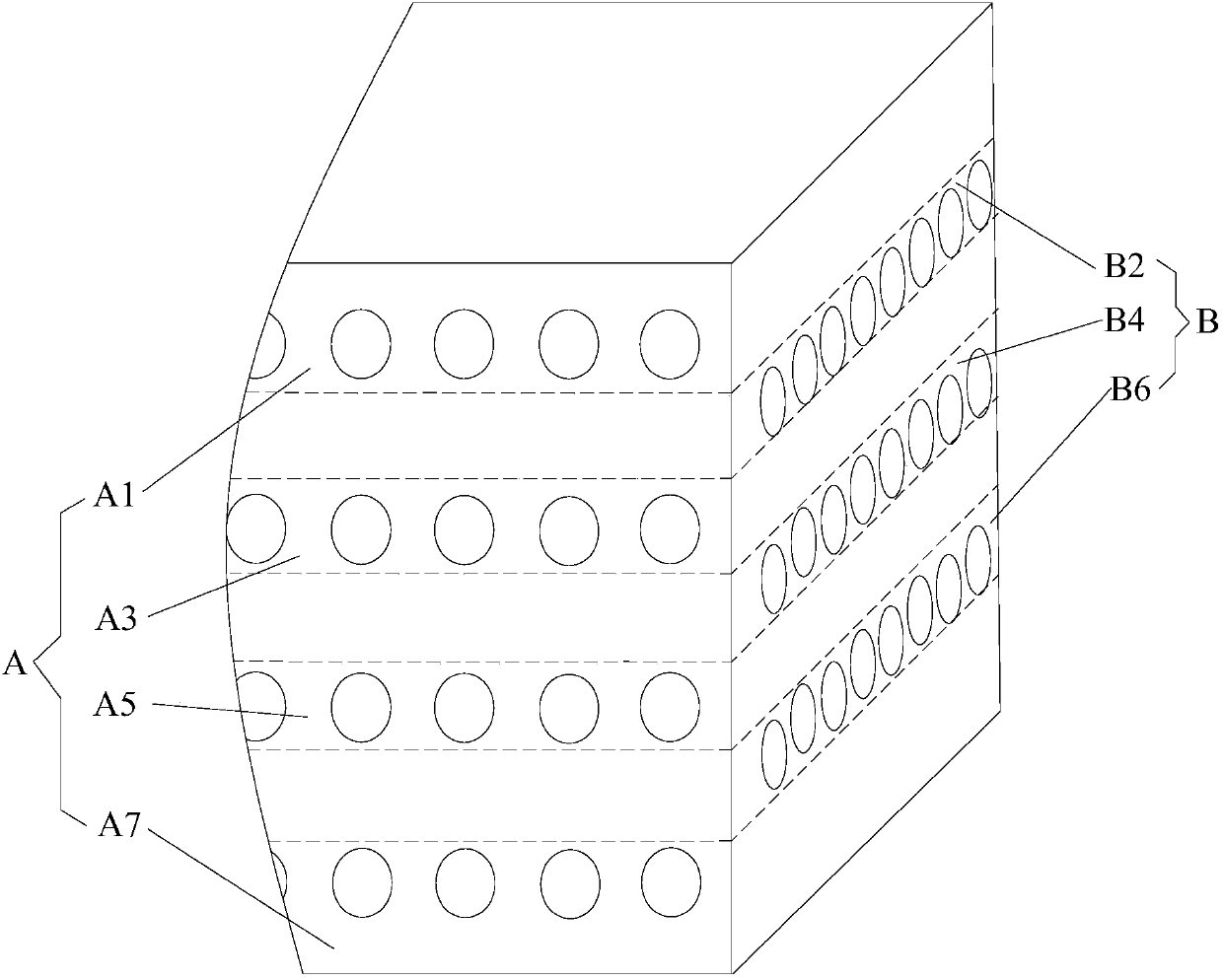

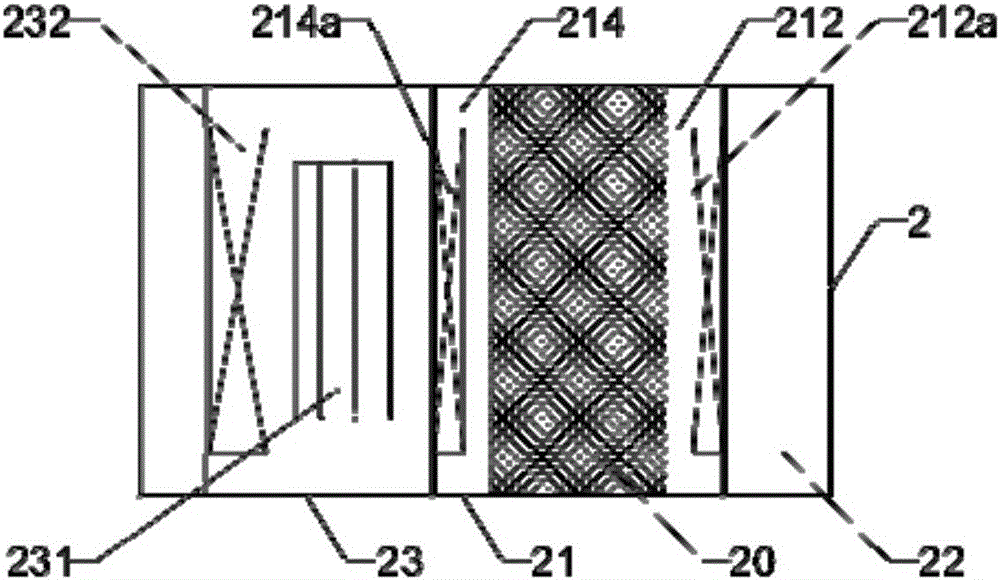

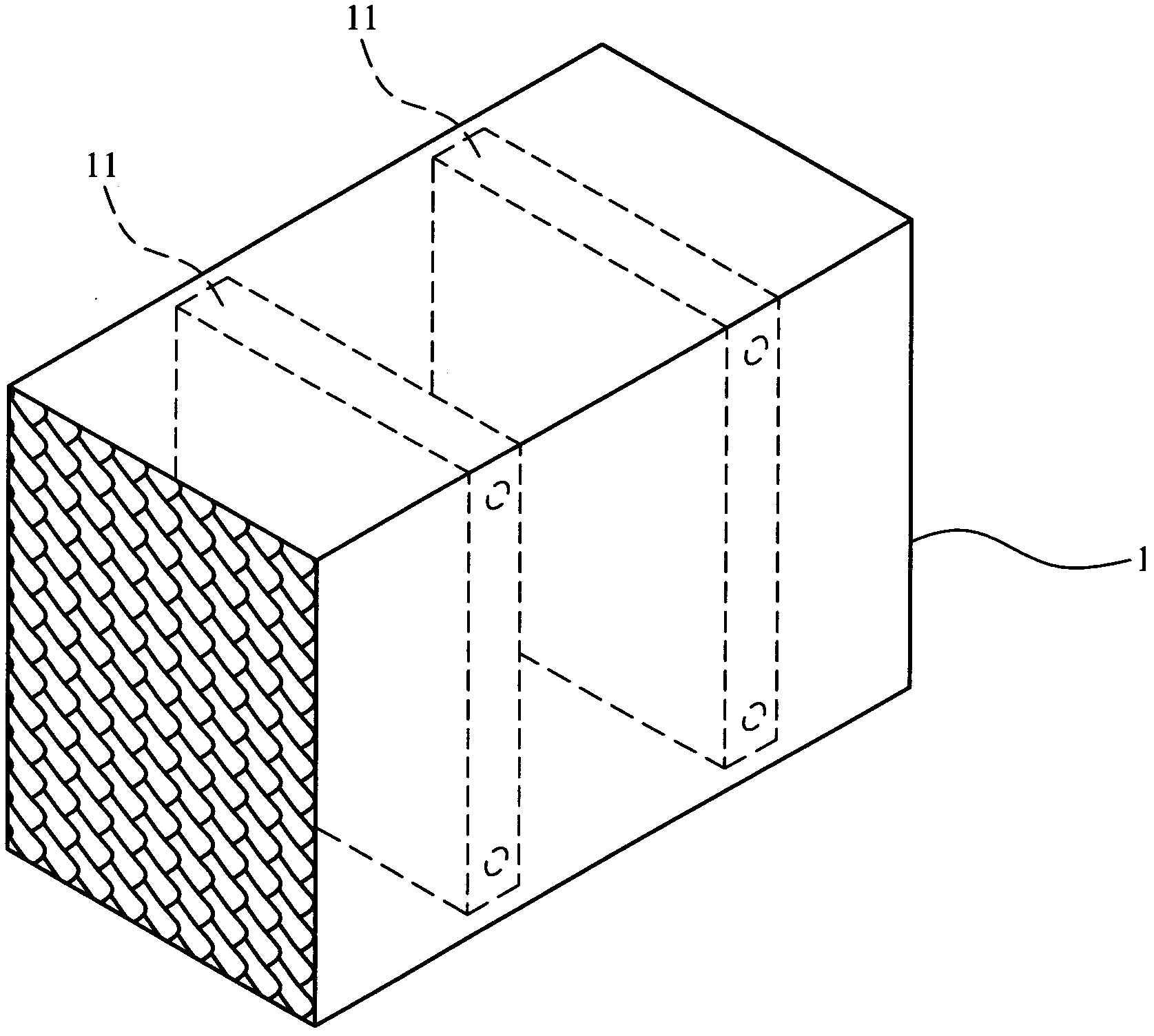

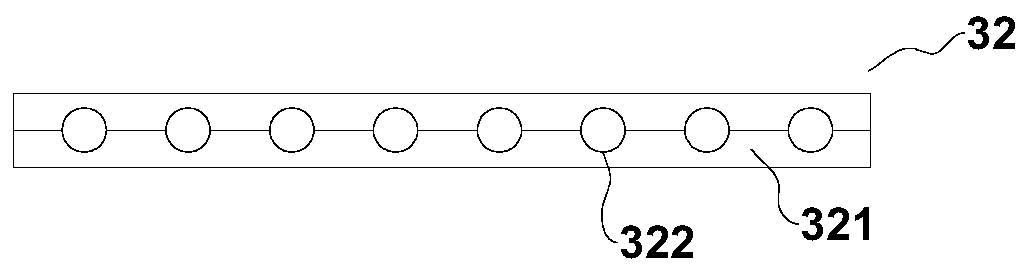

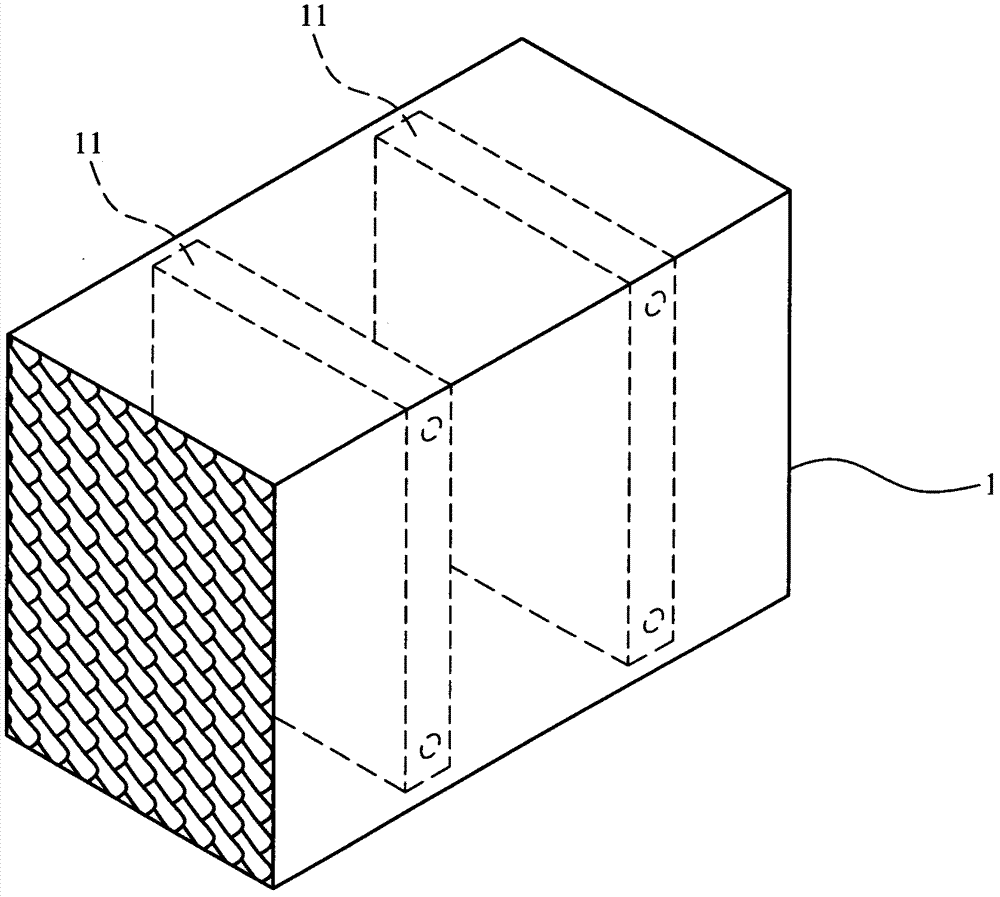

Dividing wall type heat exchanger

InactiveCN105509513AWith heat exchange functionWith characteristicsHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerSolid structure

The invention discloses a dividing wall type heat exchanger, comprising a heat exchange core and four covers; the heat exchange core has a solid structure made of a heat-conducting material; a plurality of first through holes and a plurality of second through holes not communicating with the first through holes are formed in the heat exchange core; the first through holes penetrate through two front and back opposite side surfaces of the heat exchange core, while the second through holes penetrate through two left and right opposite side surfaces of the heat exchange core; the four covers corresponding to the four front and back, and left and right side surfaces of the heat exchange core one to one; four sides of each cover are hermetically connected with corresponding side surface of the heat exchange core; a connection port allowing a fluidic working medium to flow in is formed in each cover and each connection port communicates with all the first through holes or the second through holes in the corresponding side surface. The heat exchange core of the dividing wall type heat exchanger has a heat exchange function, and also the characteristics of a heat exchanger body, and is unique in structure, and simple and compact in structure, and therefore, small-volume and low-cost production and manufacture can be realized; especially, the heat exchange core of the dividing wall type heat exchanger is suitable for the microelectronic industry and may produce good economic benefits.

Owner:常熟皓璟兄弟照明设计工程有限公司

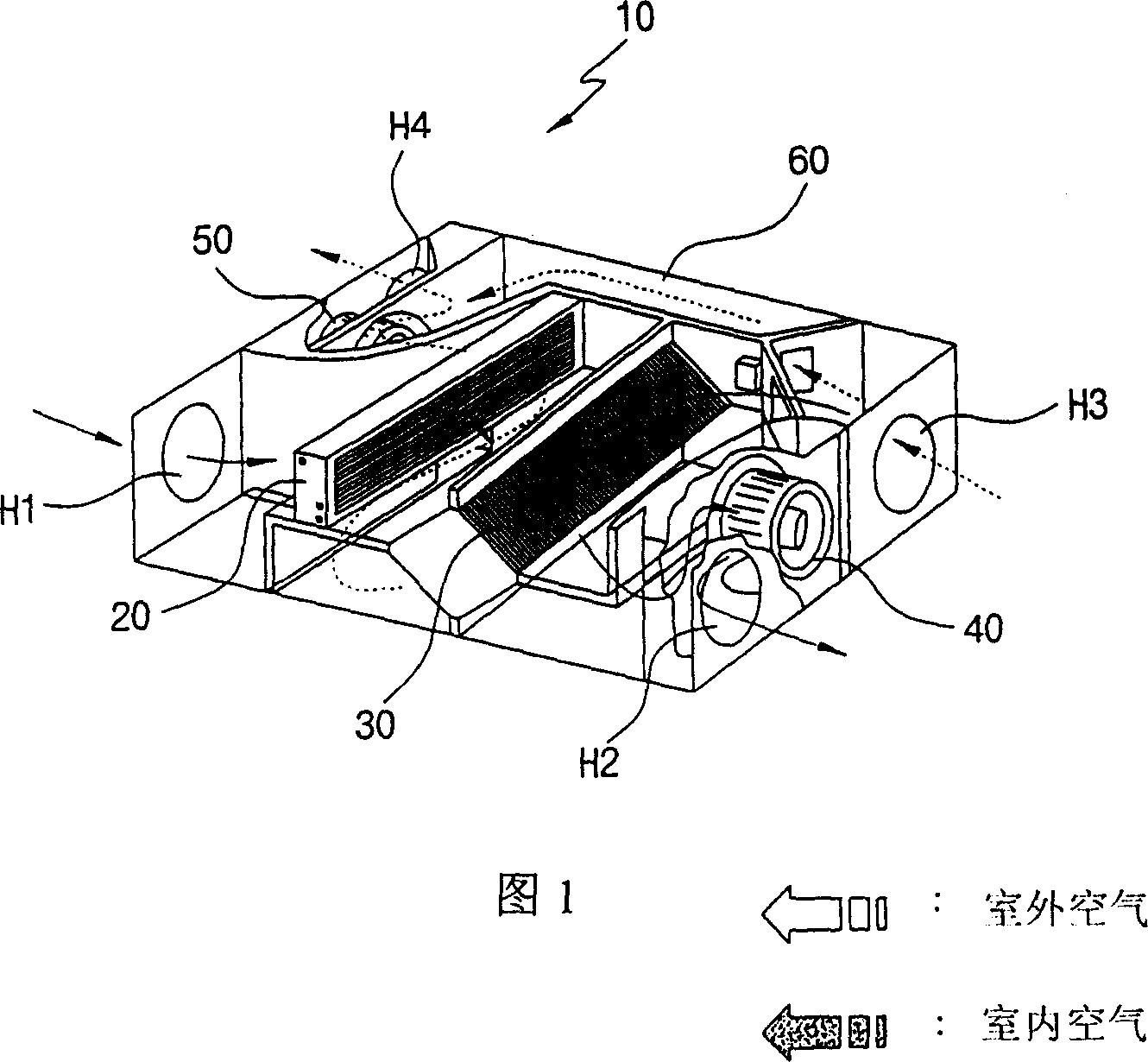

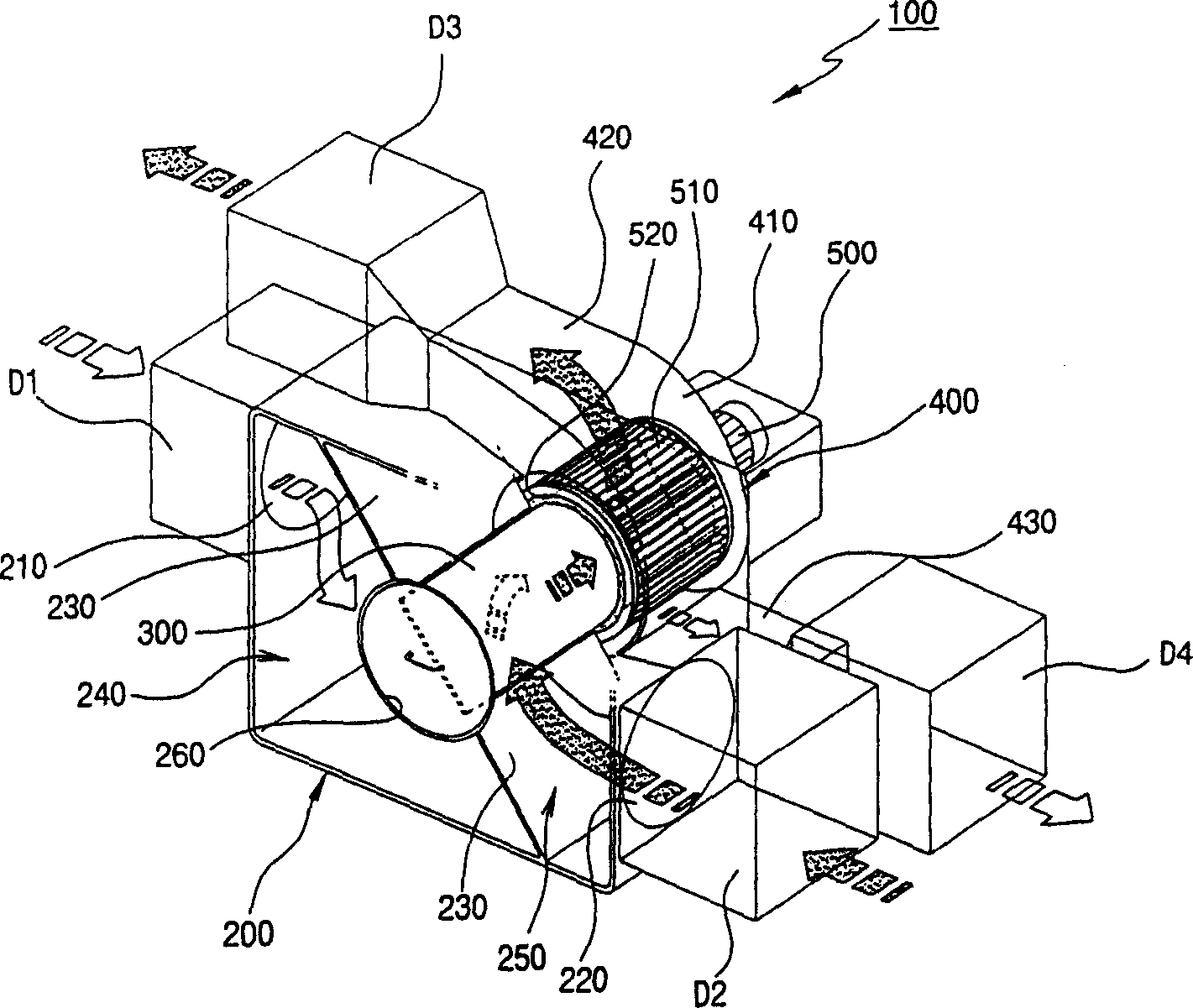

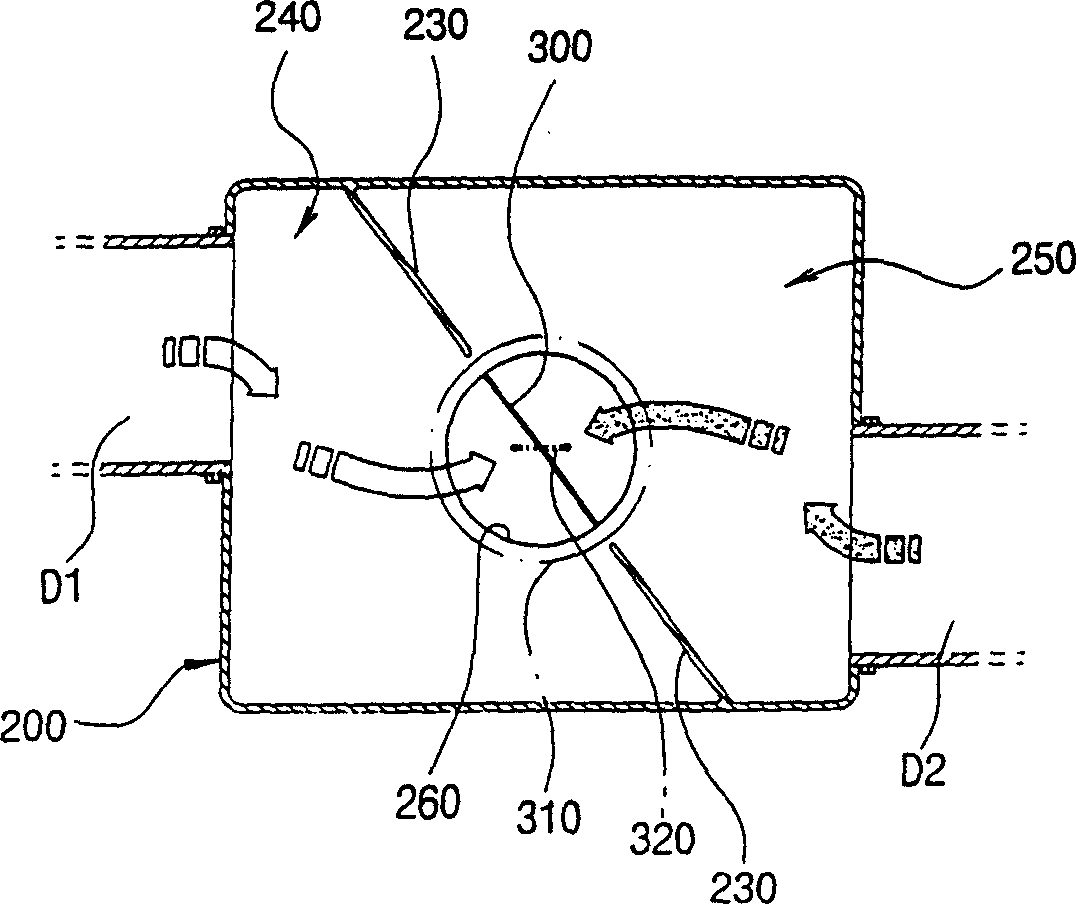

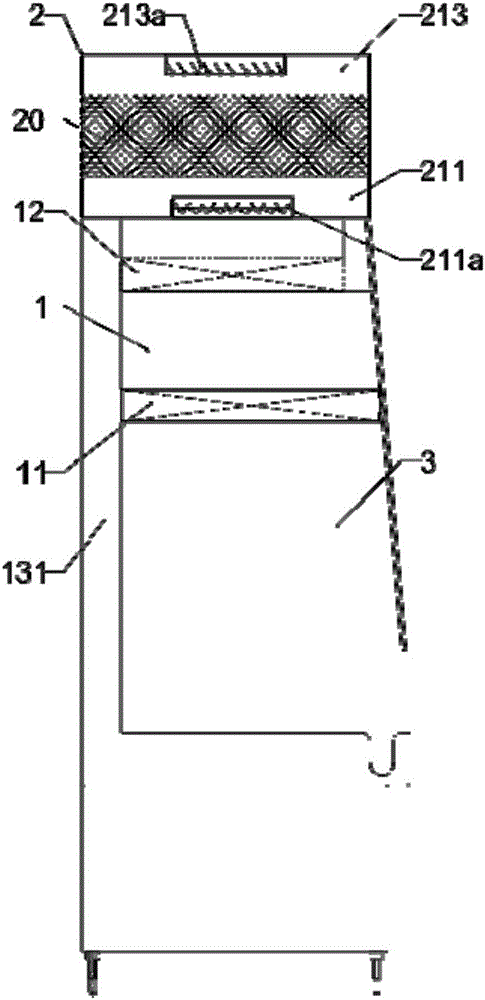

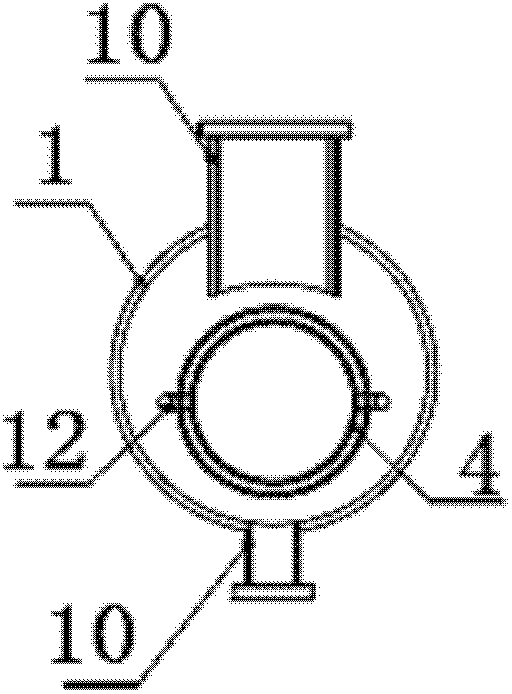

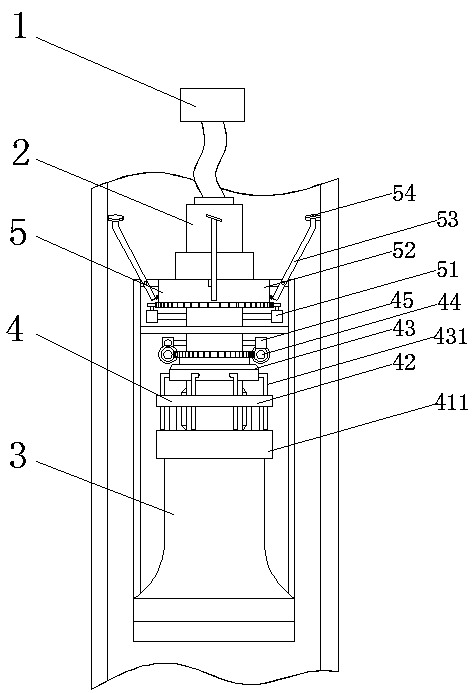

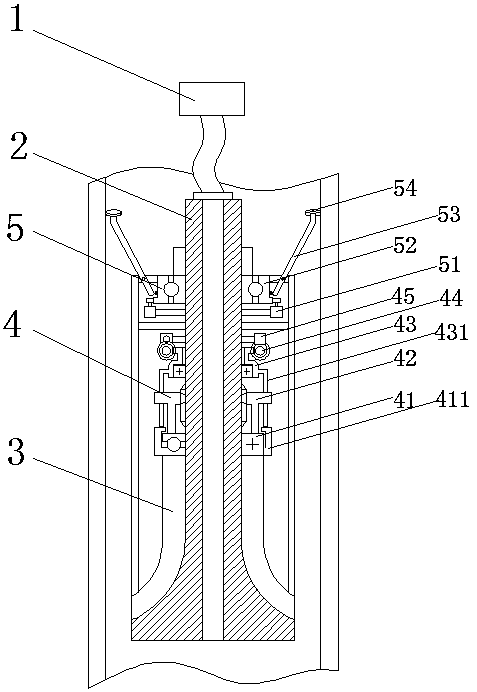

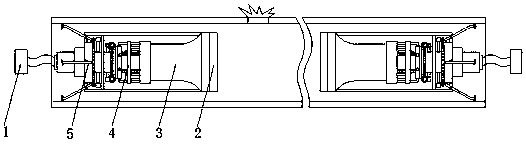

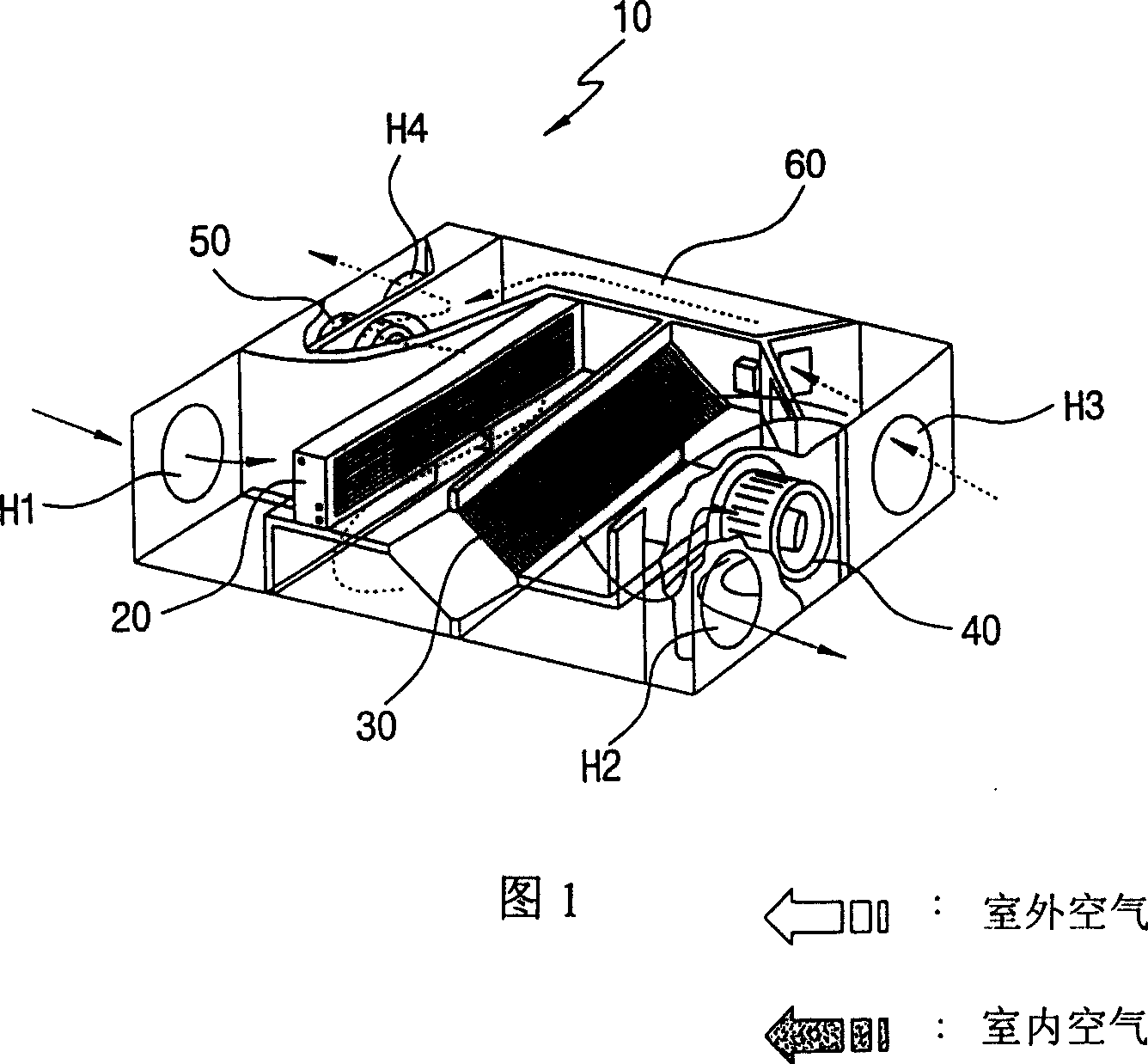

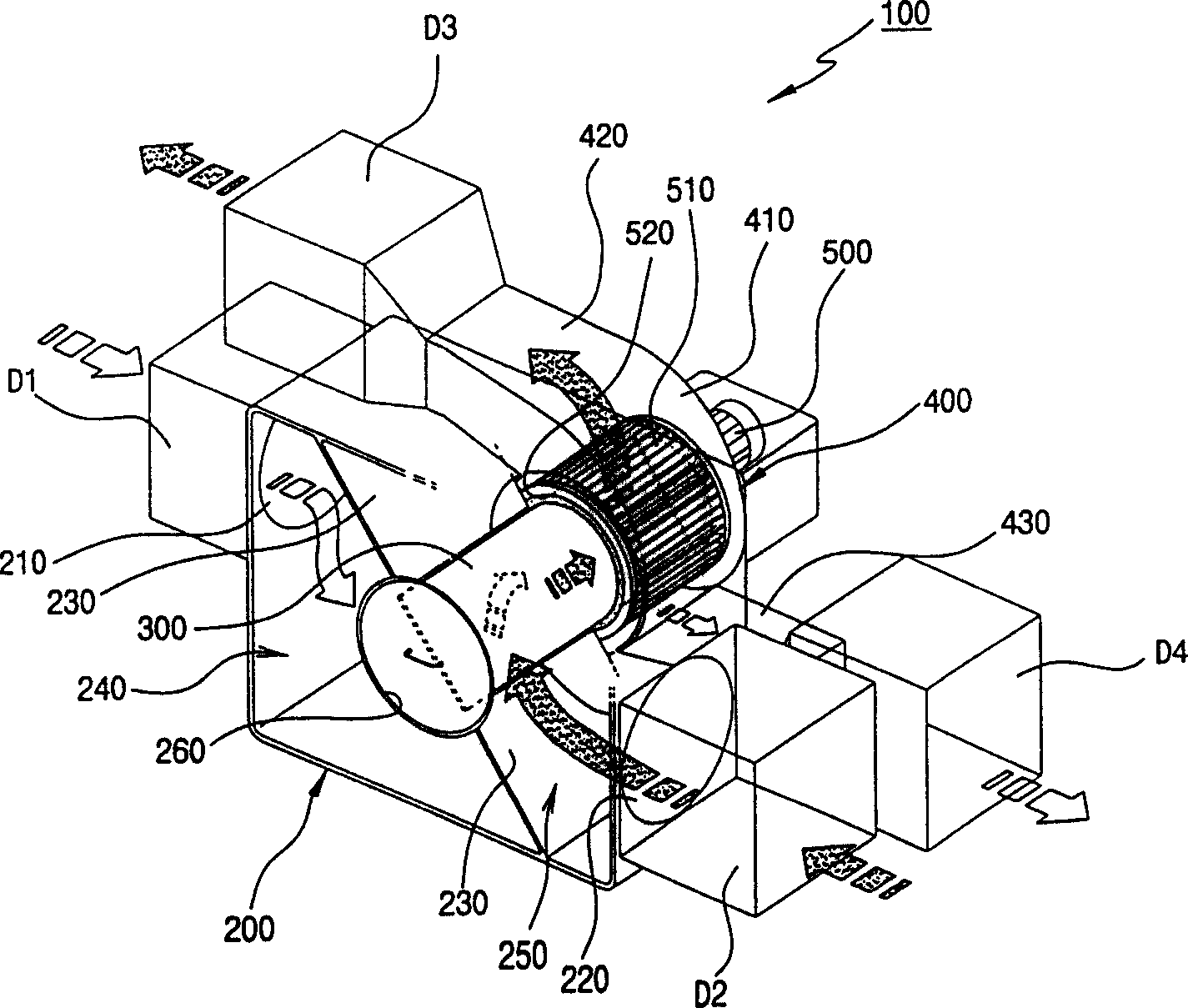

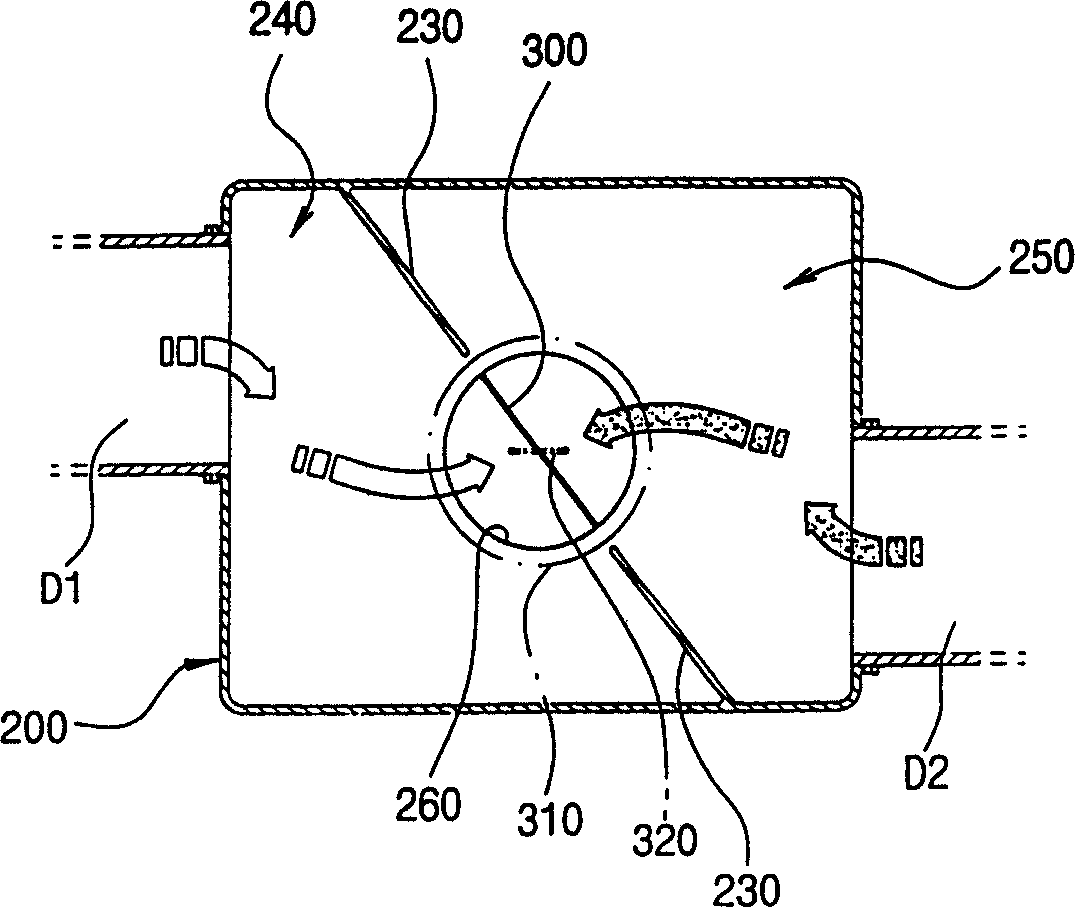

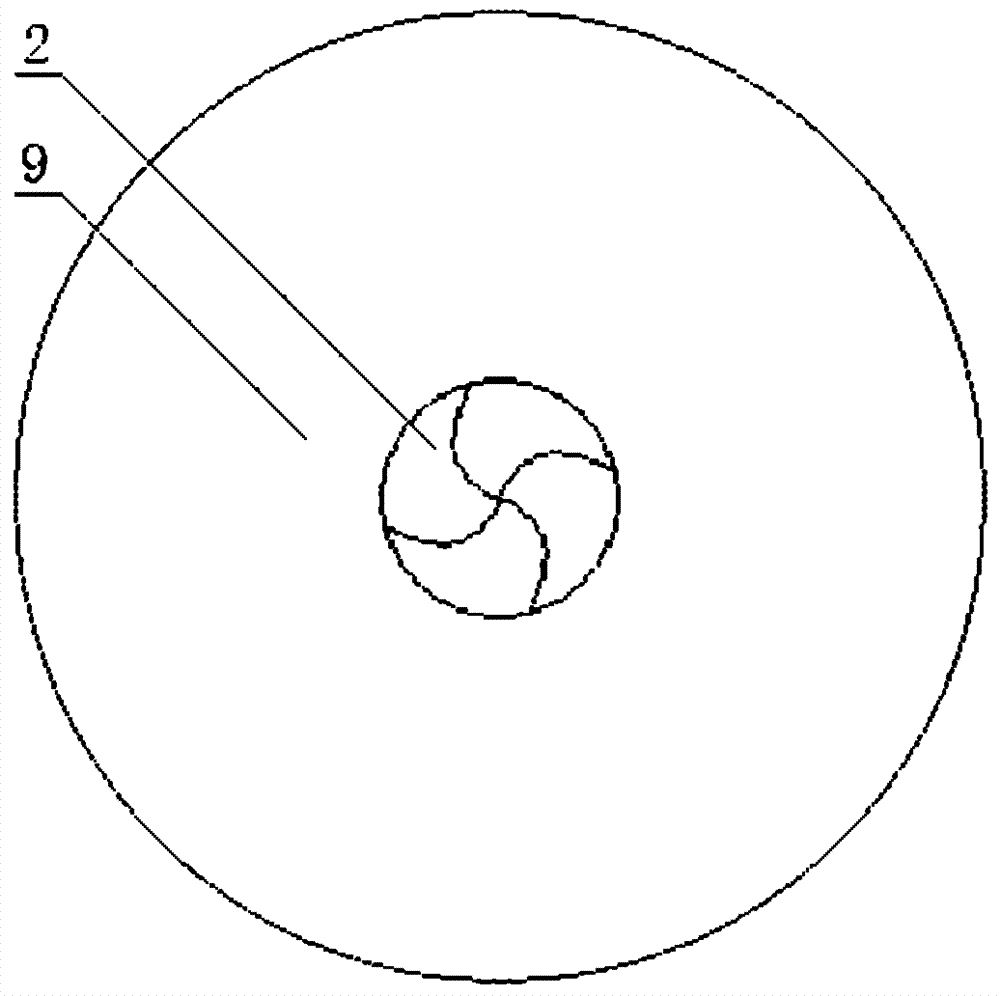

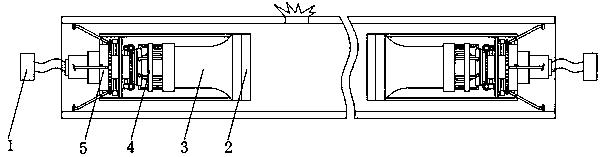

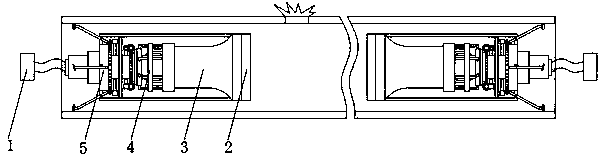

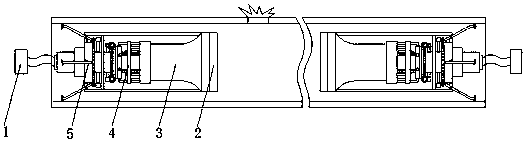

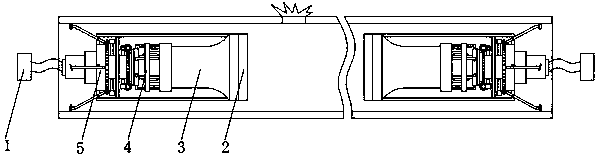

Single ventilation device with heat exchange function

InactiveCN1517629AWith heat exchange functionEnergy recovery in ventilation and heatingHeat recovery systemsImpellerAir separation

PURPOSE: A single blower system for exchanging heat and ventilating is provided to reduce energy consumption by actively supplying and exhausting air and recovering exhaust heat through heat exchange with the single blower, and to cut down manufacturing cost by reducing the number of parts and noise. CONSTITUTION: A blower system for exchanging heat and ventilating is composed of a chamber case(200) having the divided portions not to mix internal air and external air and flowing internal air and external air in; an internal and external air separation plate(300) inserted to the chamber case to guide and separate external air from internal air; and a single blower(400) exchanging heat and filtering external air and internal air divided and guided by the internal and external air separation plate, and supplying external air indoors and discharging internal air outdoors.

Owner:朴凤泰

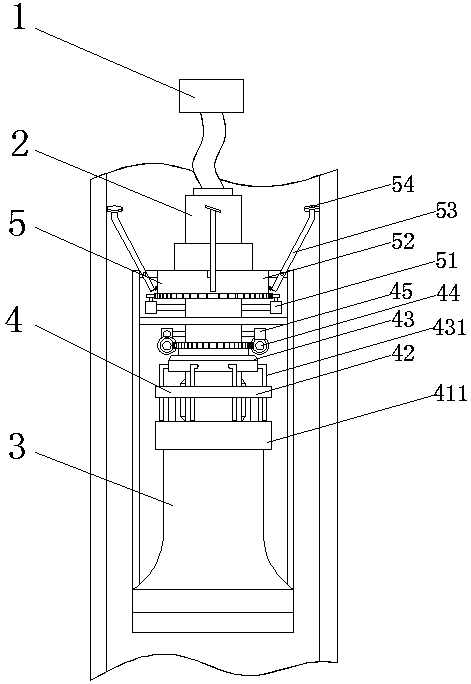

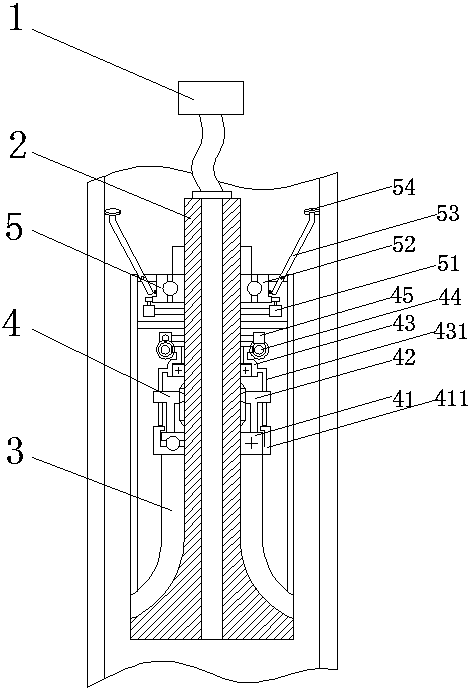

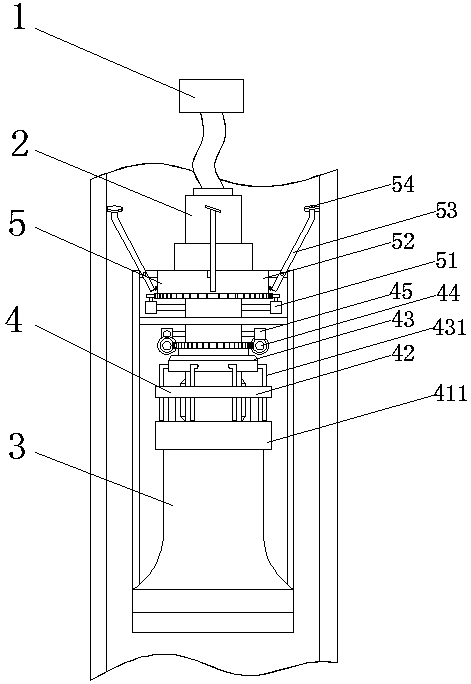

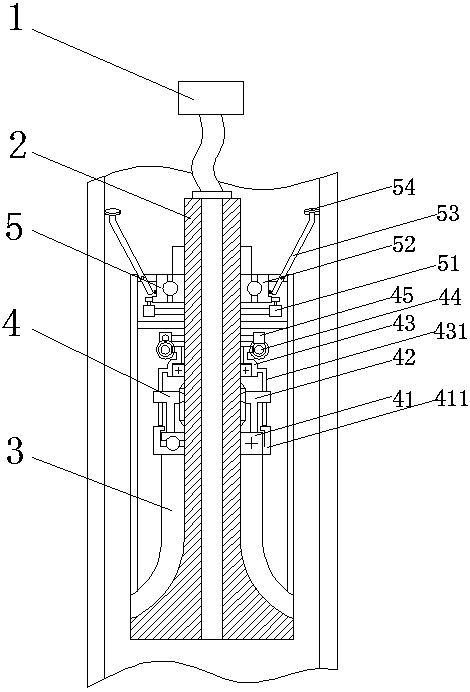

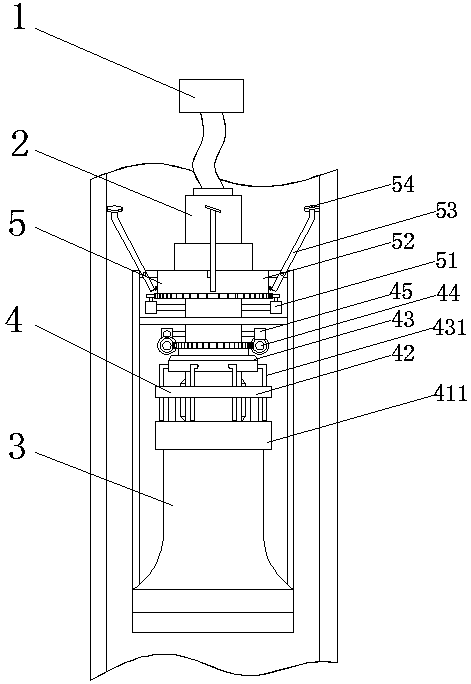

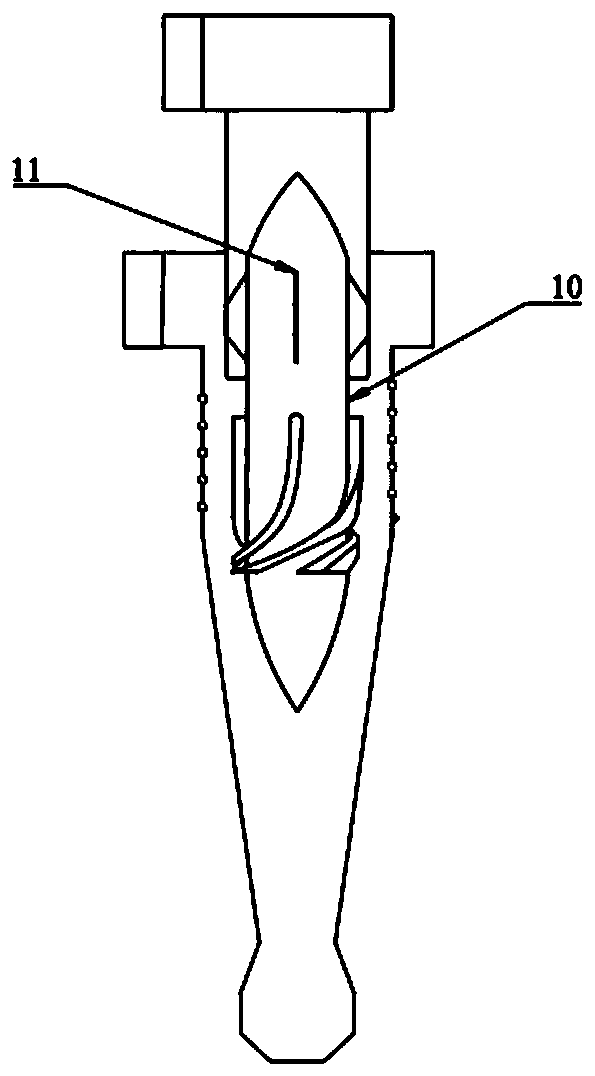

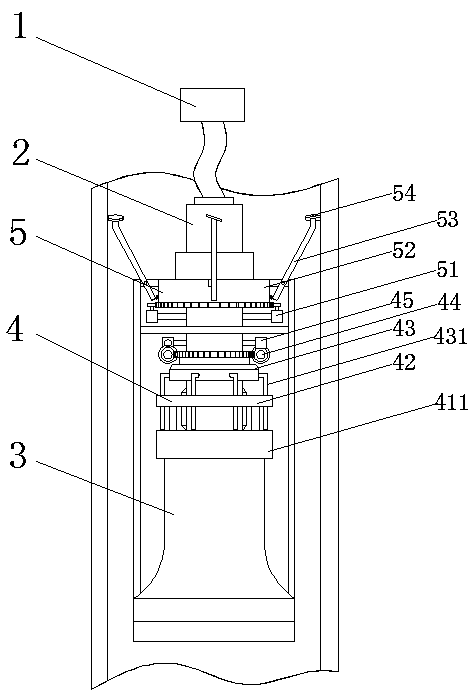

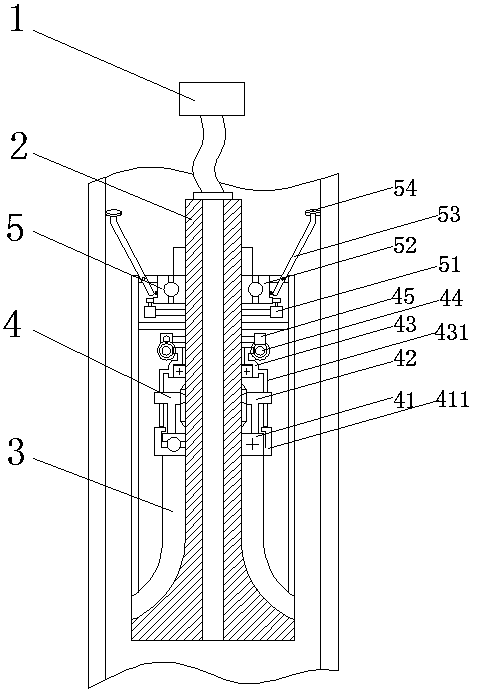

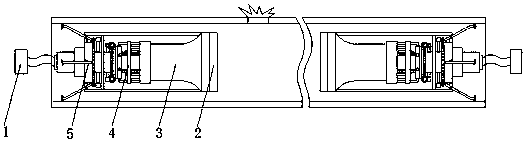

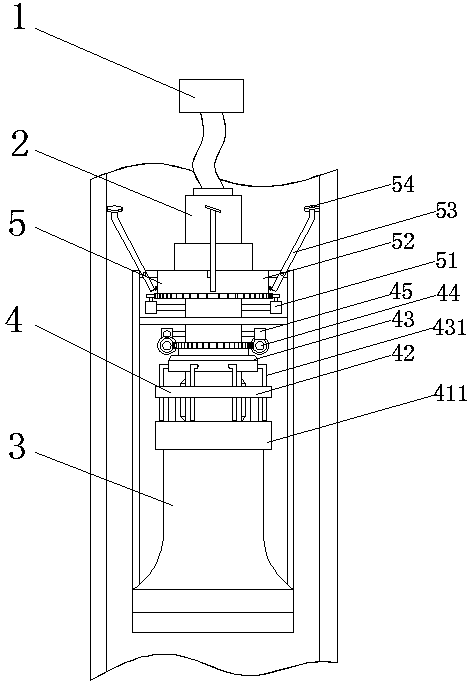

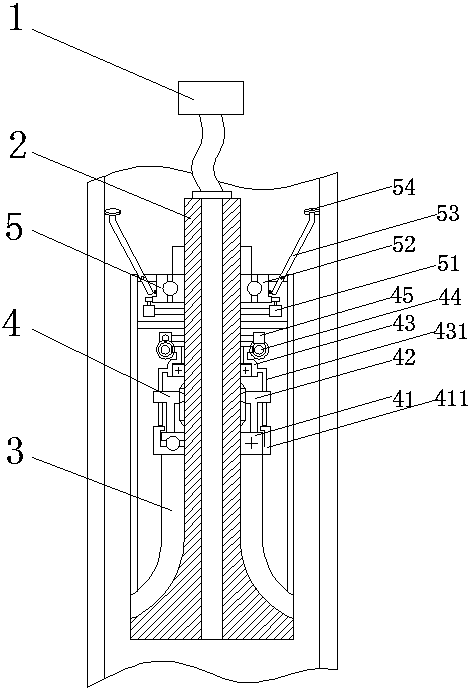

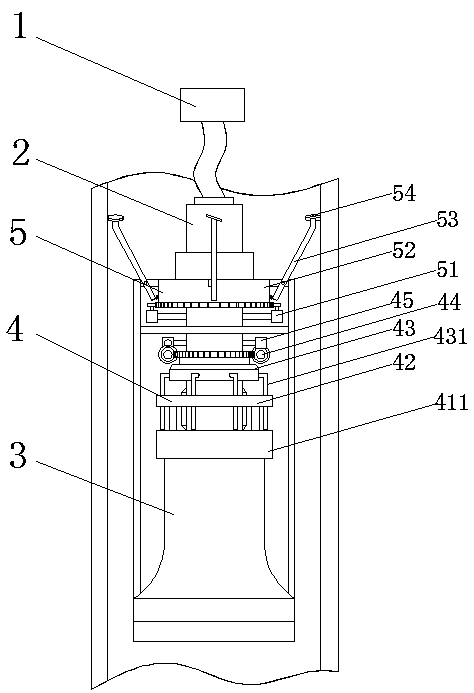

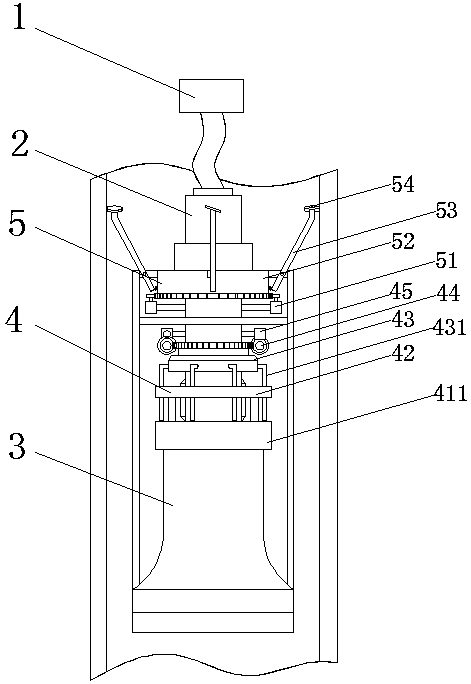

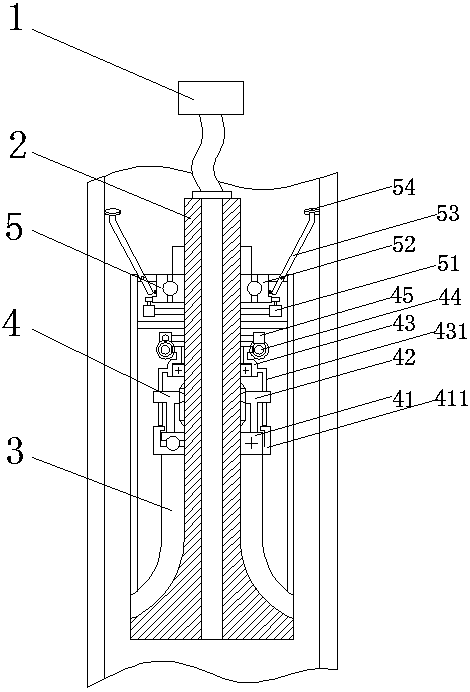

Central air conditioning heat exchange tube leak point detecting device

ActiveCN108318192ASave human effortAccurate detectionMeasurement of fluid loss/gain rateCentral air conditioningEngineering

The invention relates to the technical field of central air-conditioning, in particular to a central air-conditioning heat exchange tube leakage point detecting device. The central air-conditioning heat exchange tube leakage point detecting device comprises: an industrial personal computer, a detecting head, a plugging casing pipe, a casing pipe extruding device and a probe moving device; the detecting head is connected to the industrial personal computer through a vacuum tube; the lower end of the detecting head has a plugging casing pipe sleeve; the center of the detecting head is sleeved with the casing pipe extruding device; the probe moving device sleeves the upper end of the detecting head; a repairing device comprises an elastic sleeve, expansion rings and a locking mechanism, wherein each of both ends of the elastic sleeve is provided with an expansion ring, the two expansion rings are sleeved inside the elastic sleeve, and the locking mechanism is clamped on the two expansionrings; segmentation pressure maintaining test of the interior of the heat exchange tube can be achieved, the position of a leak point inside the heat exchange tube can be found; the locking mechanismdrives the two expansion rings to fix the elastic sleeve inside the heat exchange tube, and then the leak point of the heat exchange point is repaired.

Owner:河北纳森空调有限公司

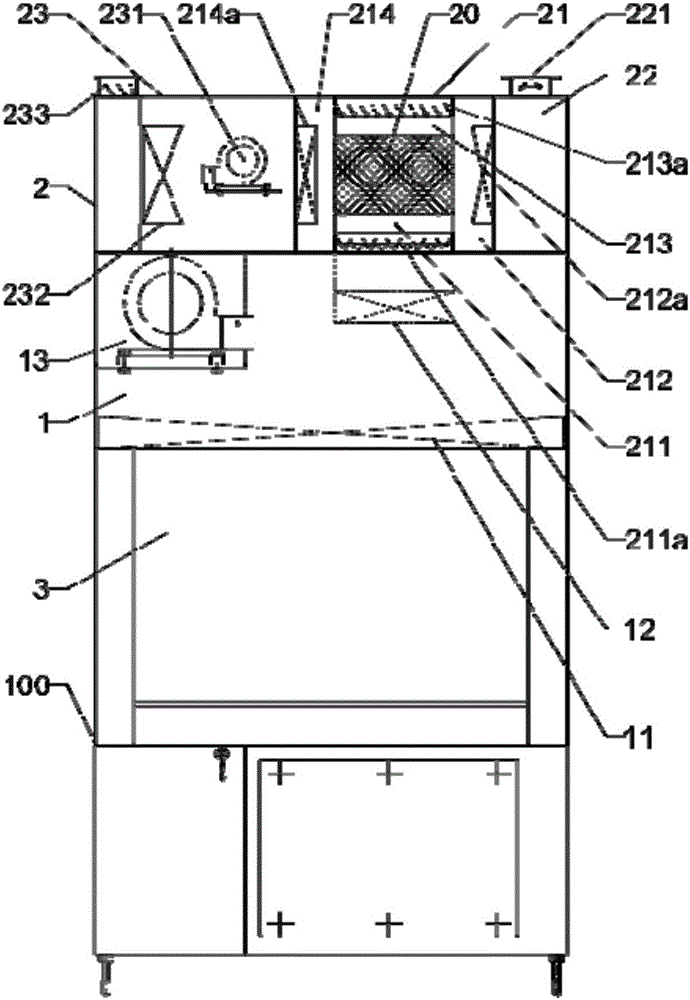

Biological safety cabinet with function of heat exchange

ActiveCN105689025AWith heat exchange functionEnsure air cleanlinessDust-free enclosuresHazardous material storageLoad following power plantFilter element

The invention relates to a biological safety cabinet with a function of heat exchange. The biological safety cabinet comprises a cabinet body, an operation chamber and an efficient filtering heat exchange unit. The cabinet body is provided with an air supply filter and an exhaust filter and communicated with the operation chamber through the air supply filter, and a circulating fan is arranged in the cabinet body. The efficient filtering heat exchange unit comprises a heat exchange tank, a fresh air tank and an efficient air supply tank, and the heat exchange tank consists of a heat exchange filter element and four buffer boxes in hermetical connection with four ventilation faces of the heat exchange filter element. The biological safety cabinet has the advantages that air cleanliness of the operation chamber is guaranteed, and harmful aerosol is prevented from overflowing from the operation chamber, so that health of operators is guaranteed; burdens of a laboratory air conditioning system can be effectively relieved, energy consumption is reduced, and service lives of parts are prolonged effectively; difficulty in design of a central air-conditioning ventilation system is lowered; various operating parameters of the biological safety cabinet can be regulated conveniently, and digital control and remote management of the biological safety cabinet can be realized beneficially.

Owner:东莞市鼎泰天元智能科技有限公司

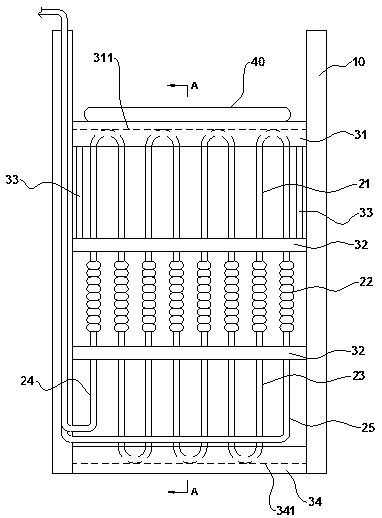

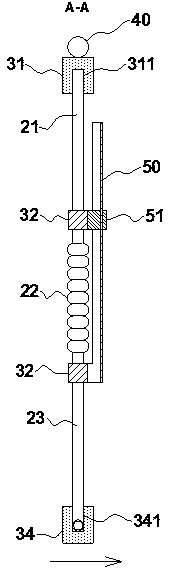

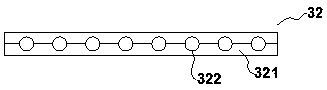

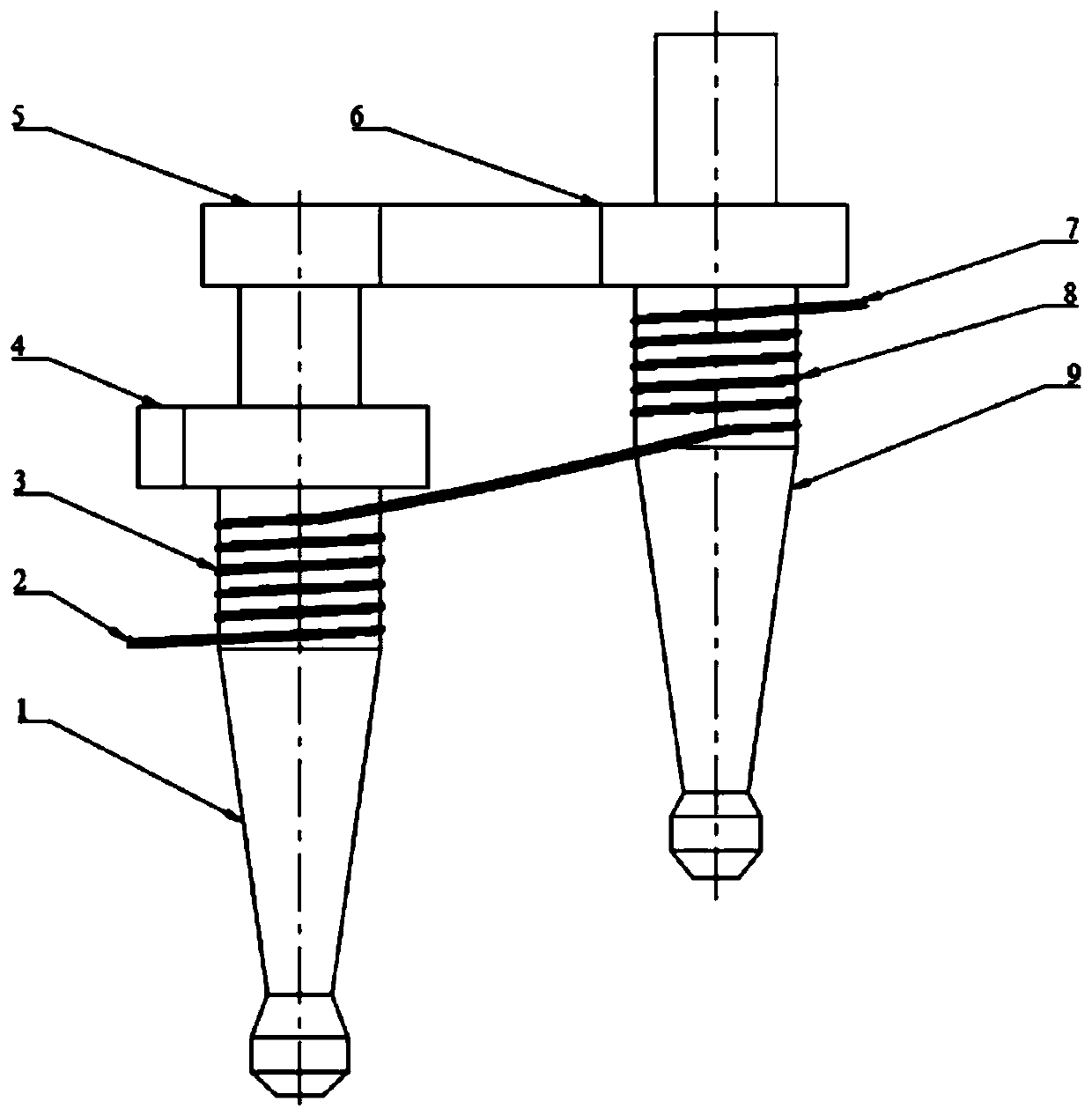

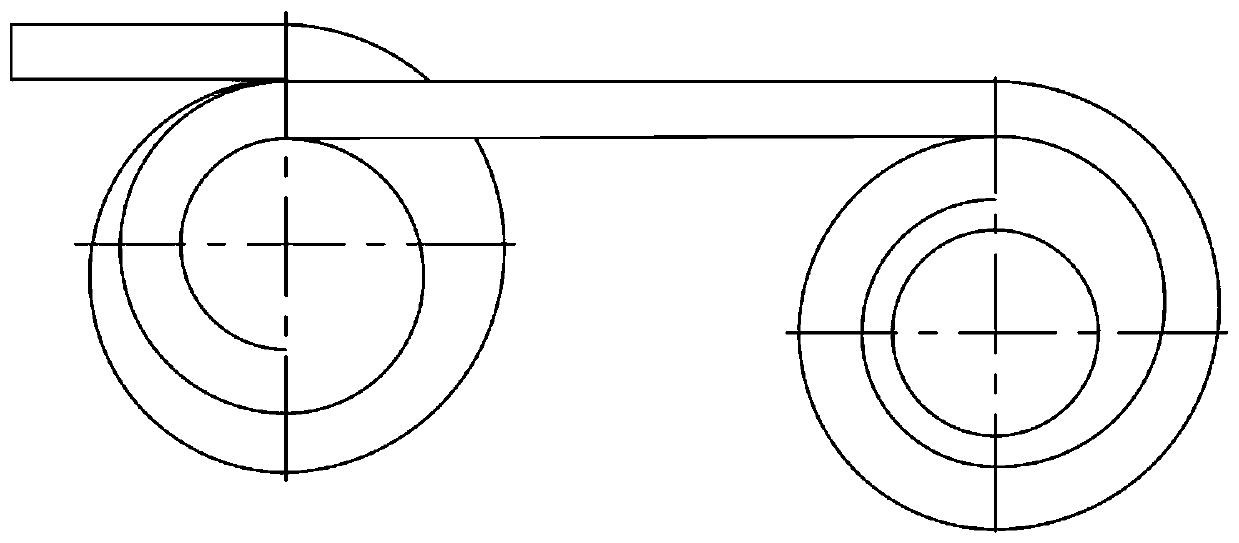

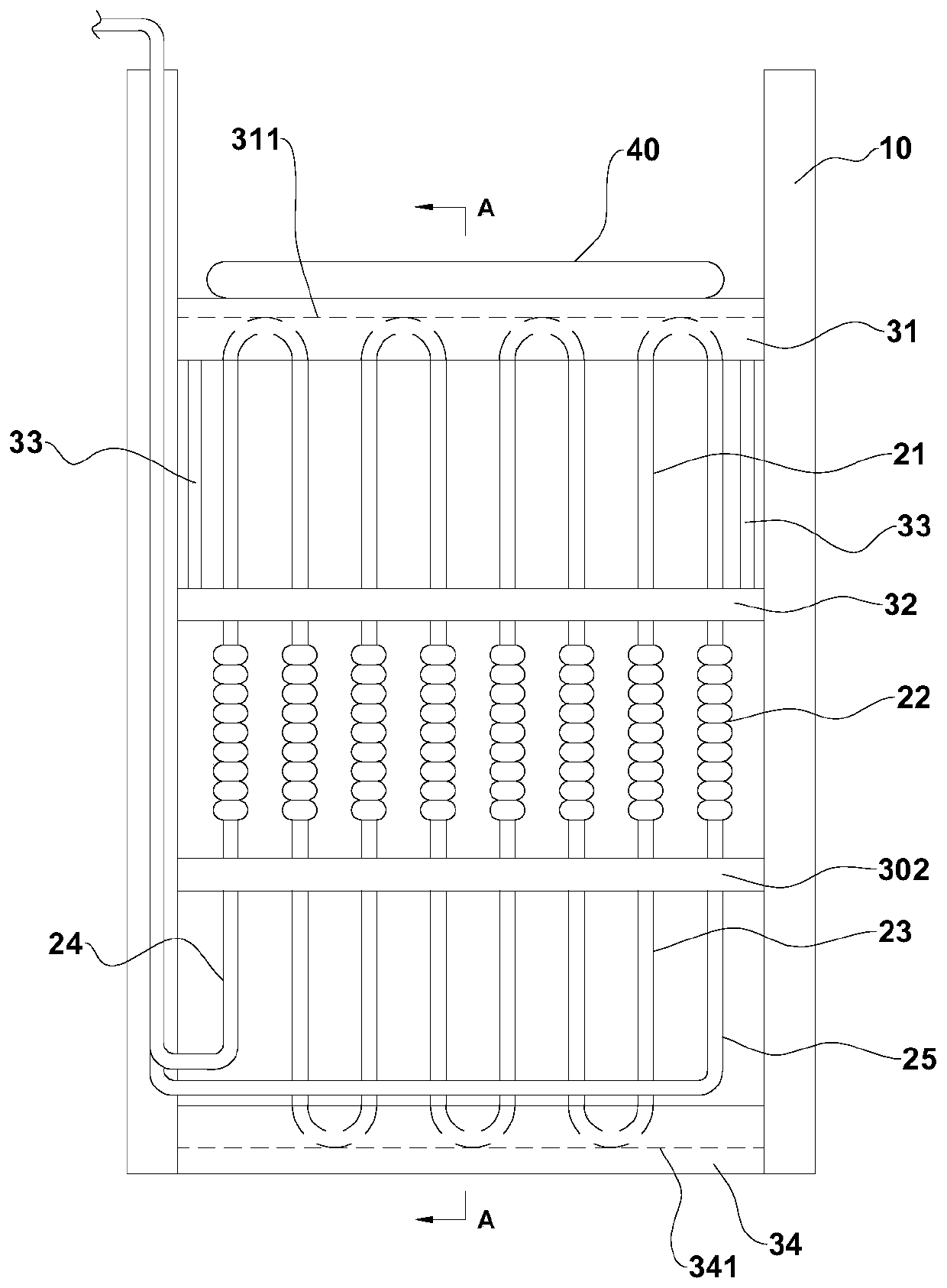

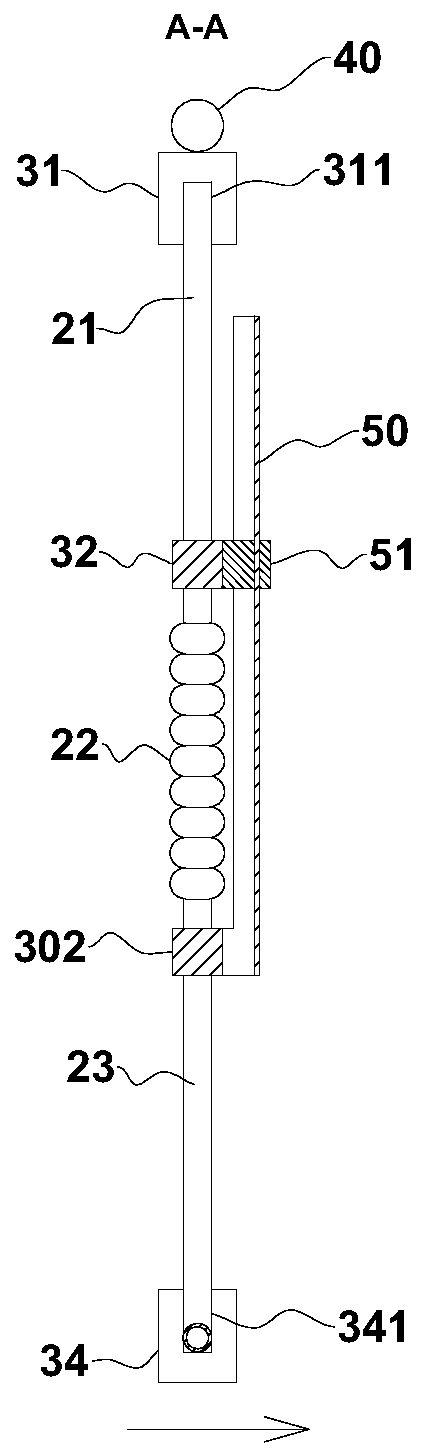

Trash rack with heat exchanging function

ActiveCN107794894AWith heat exchange functionFunctionalWater cleaningArtificial water canalsEngineeringWater level

The invention relates to a trash rack with a heat exchanging function. The trash rack with the heat exchanging function comprises two parallel vertical frames and an S-shaped heat exchanging tube, theS-shaped heat exchanging tube comprises a plurality of upper U-shaped tubes with openings facing downwards, a plurality of lower U-shaped tubes with openings facing upwards and corrugated tubes, thelower U-shaped tubes and the upper U-shaped tubes are arranged in a staggered mode, and the corrugated tubes are used for communicating the upper U-shaped tubes with the lower U-shaped tubes to enablethe whole S-shaped heat exchanging tube to be in an S shape; the upper U-shaped tubes are fixed to an upper tube frame which is slidably connected with the vertical frames, the upper end of the uppertube frame is provided with a floating body, the lower U-shaped tubes are fixed to a lower tube frame, and the lower tube frame is fixedly connected with the vertical frames; and the two upper U-shaped tubes on the outermost sides communicate with a water inlet tube and a water outlet tube through one corrugated tube correspondingly. The trash rack with the heat exchanging function has functionsof trashing holding and heat exchanging; and in addition, the height of the S-shaped heat exchanging tube can be adjusted with the water level, so that the high heat exchanging efficiency is ensured.

Owner:HUNAN ZHONGDA JINGWEI GEOTHERMY DEV TECH CO LTD

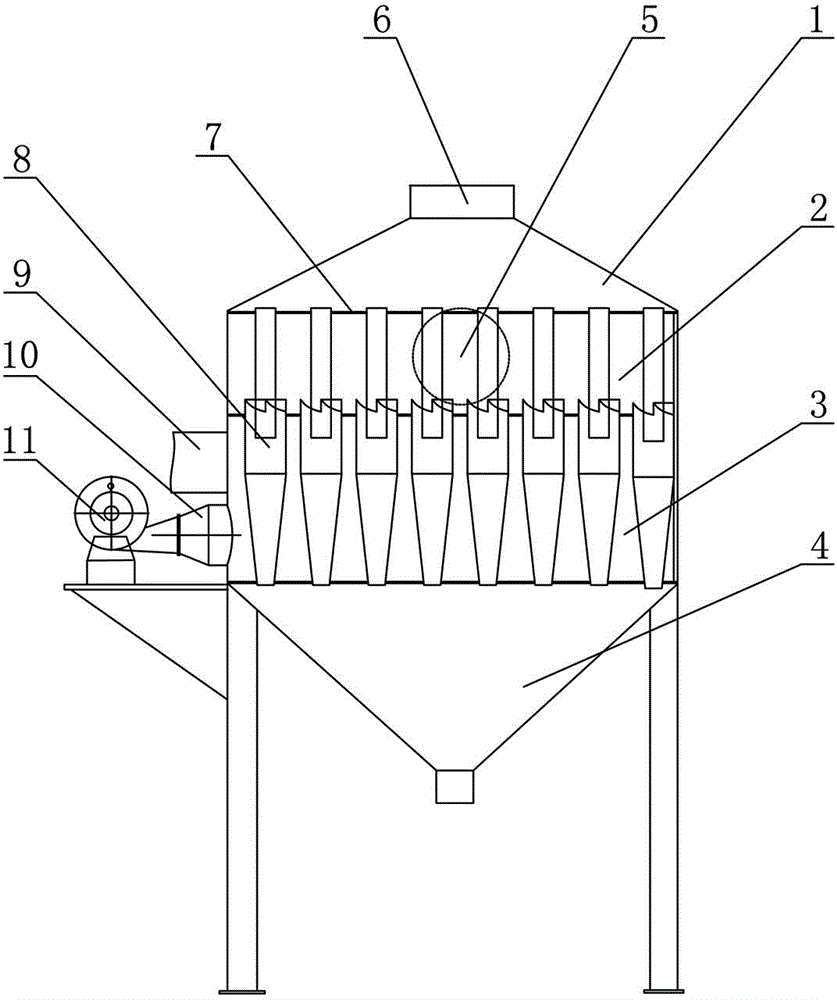

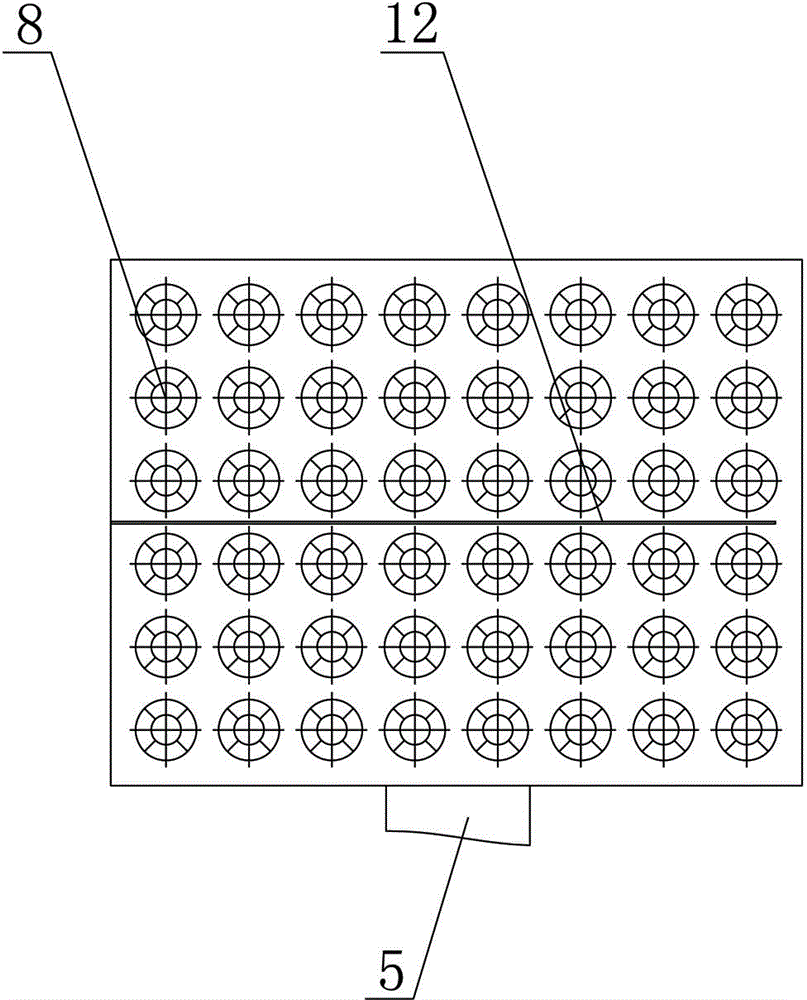

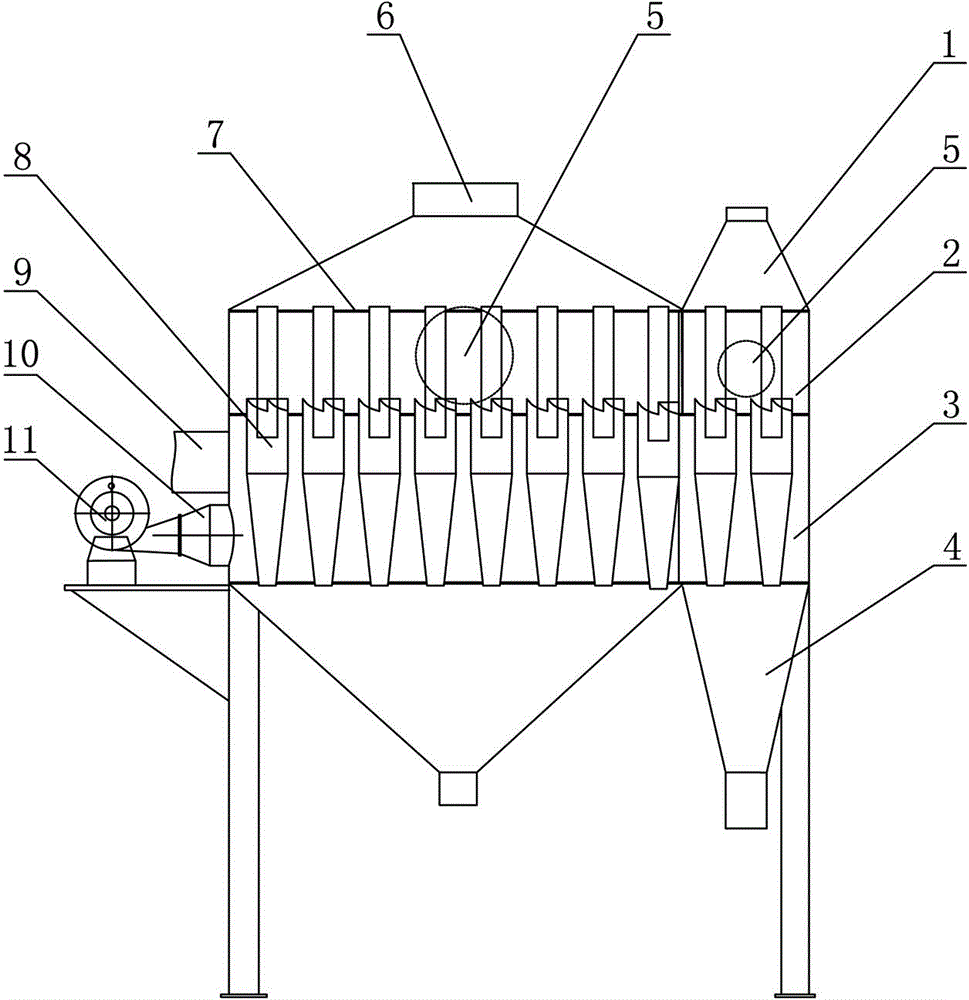

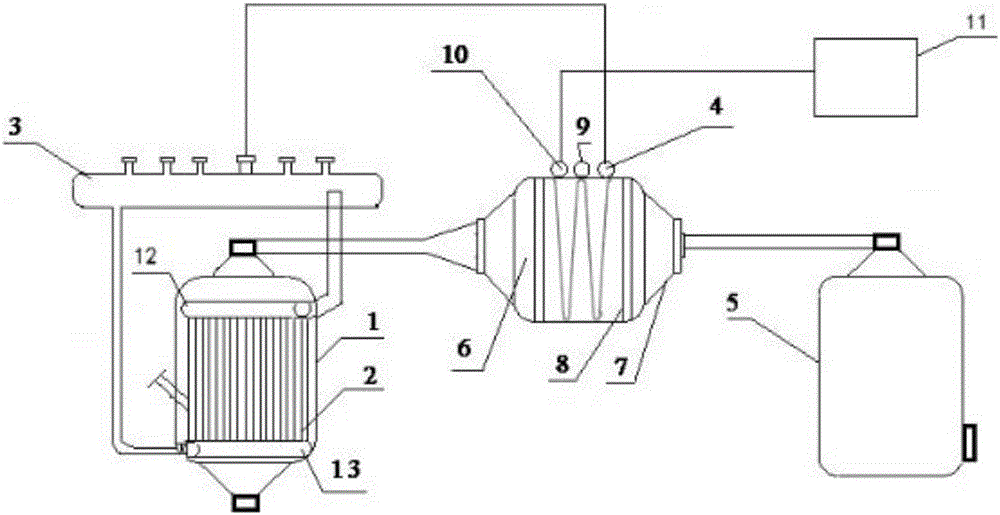

Combined heat-exchange dust remover for production of expanded perlite

InactiveCN104383754ADesign scienceWith heat exchange functionDispersed particle separationHeat exchanger casingsPerliteCold air

The invention provides a combined heat-exchange dust remover for production of expanded perlite. The combined heat-exchange dust remover comprises a shell, N rotons, an exhaust room, an air charging room, a heat exchange room and a dust removing room, wherein the N rotons are uniformly distributed in the shell; the exhaust room, the air charging room, the heat exchange room and the dust removing room are arranged in the shell from top to bottom and are separated by baffle plates; a roton air inlet of each roton is communicated with the air charging room, a roton air outlet of each roton is communicated with the exhaust room, and a roton ash discharging opening of each roton is communicated with the dust removing room; the heat exchange room is provided with a cold air inlet and a hot air outlet. To a parallel-connection combined heat-exchange dust remover for the production of the expanded perlite, all the heat exchange rooms are communicated to form a heat exchange passage, and the heat exchange passage is provided with a cold air inlet and a hot air outlet. The combined heat-exchange dust remover for the production of the expanded perlite has the advantages that the design is scientific, the heat exchange and dust removal functions are doubled, and the resource is reasonably utilized. The parallel-connection combined heat-exchange dust remover for the production of the expanded perlite has the advantages that the design is scientific, and various heat mediums exchange the heat at the same time.

Owner:XINYANG KAIMITE ENVIRONMENTAL ENG

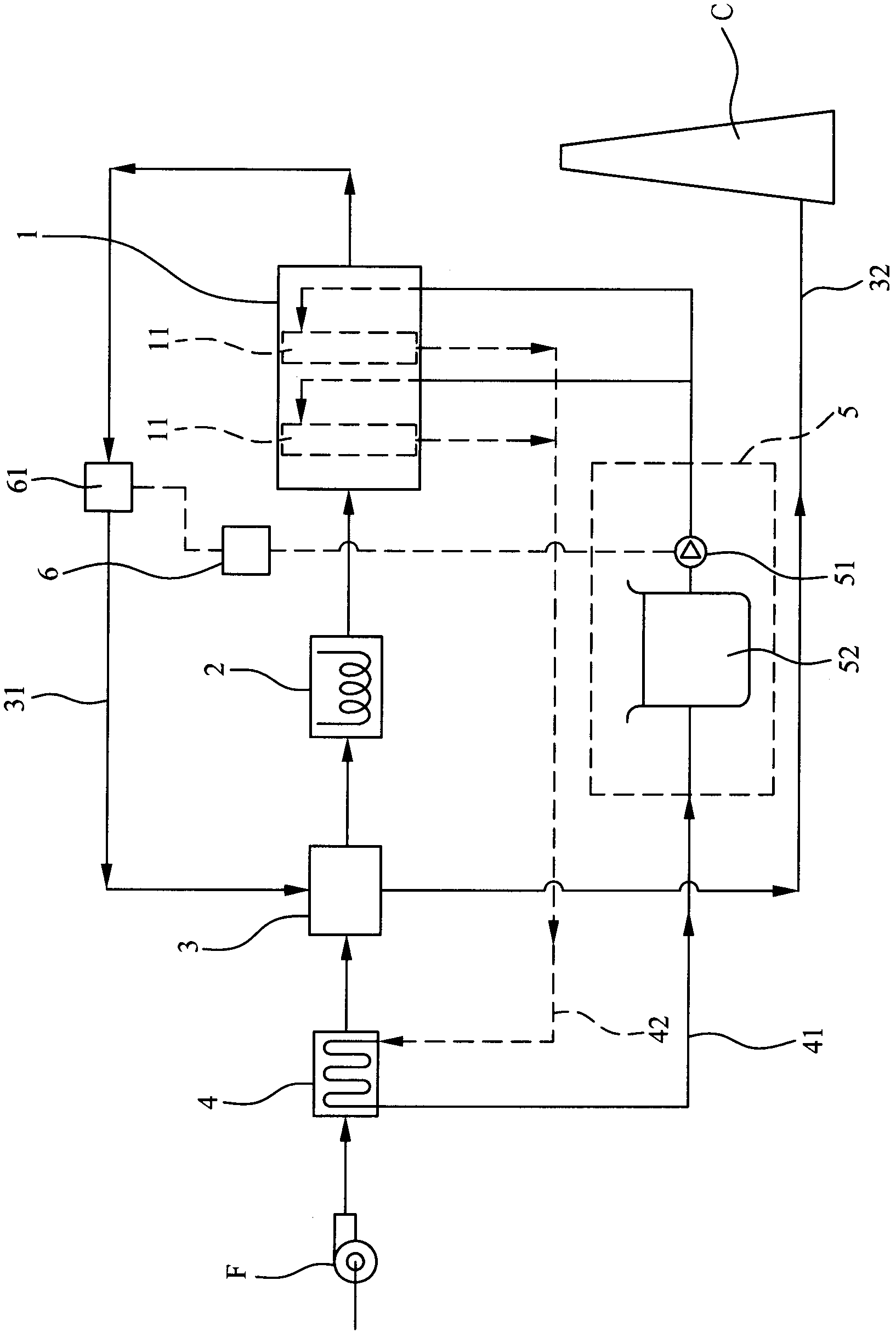

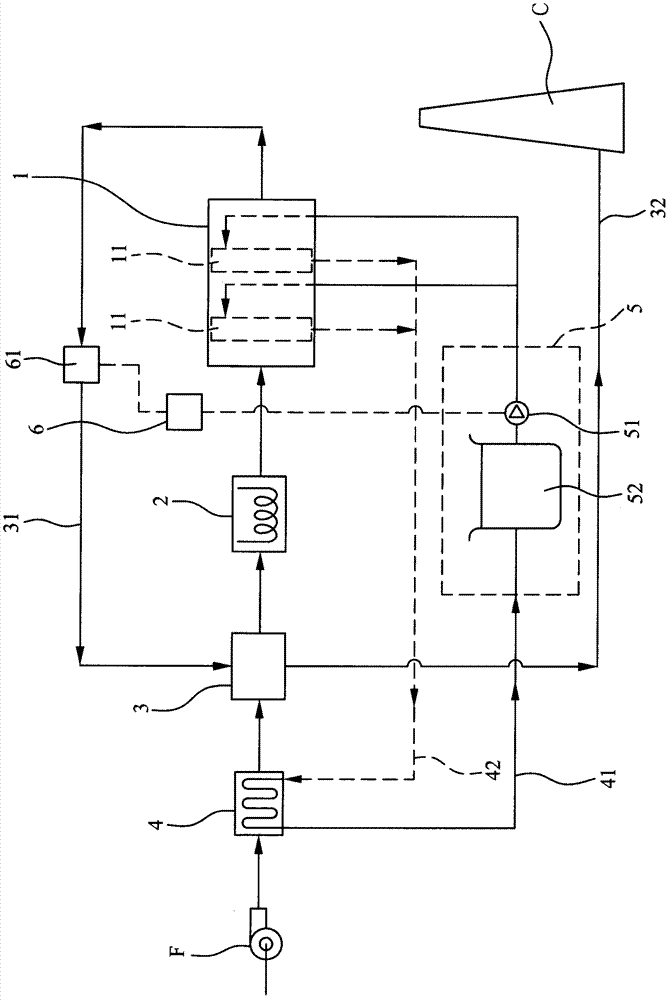

Catalytic thermal oxidizer with sintering prevention function and sintering prevention method thereof

ActiveCN102840590APrevent sinteringSo as not to damageIncinerator apparatusHeat flowProcess engineering

The invention relates to a catalytic thermal oxidizer with sintering prevention function and a sintering prevention method thereof. The catalytic thermal oxidizer comprises a first heat exchanger, a heater and a catalyst bed with entrance and exit, wherein a plurality of cooling devices are arranged in the catalyst bed; a second heat exchanger arranged before the first heat exchanger, wherein a heat flow pipeline is connected between the second heat exchanger and each cooling device of the catalyst bed; a cooling liquid supply and transport device, wherein a cold flow pipeline is connected among the second heat exchanger, the cooling liquid supply and transport device and each cooling device of the catalyst bed; and a controller with a temperature sensor, wherein the temperature sensor is arranged on the exit of the catalyst bed to sense wherein the temperature on the exit exceeds the preset temperature or not, furthermore the start and stop of the cooling liquid supply and transport device is controlled by the controller, so as to automatically reduce the temperature of the catalyst bed and prevent sintering.

Owner:DESICCANT TECH CORP

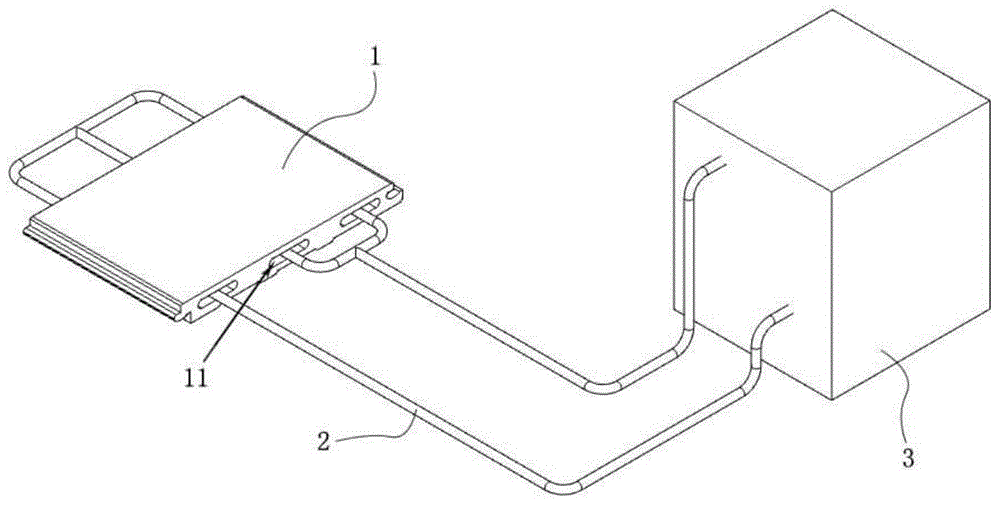

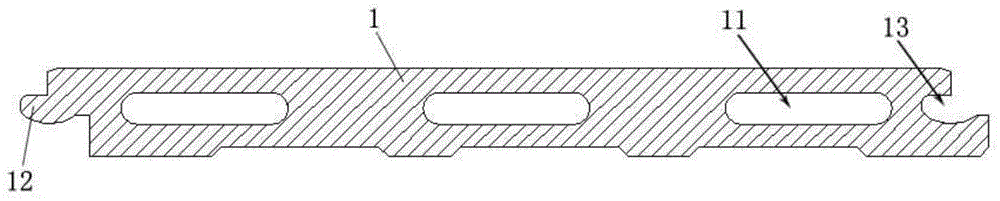

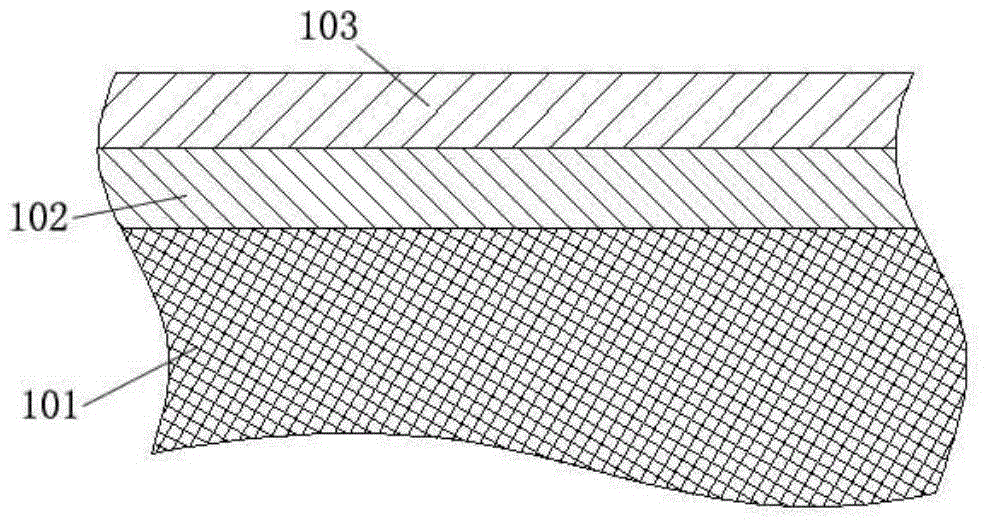

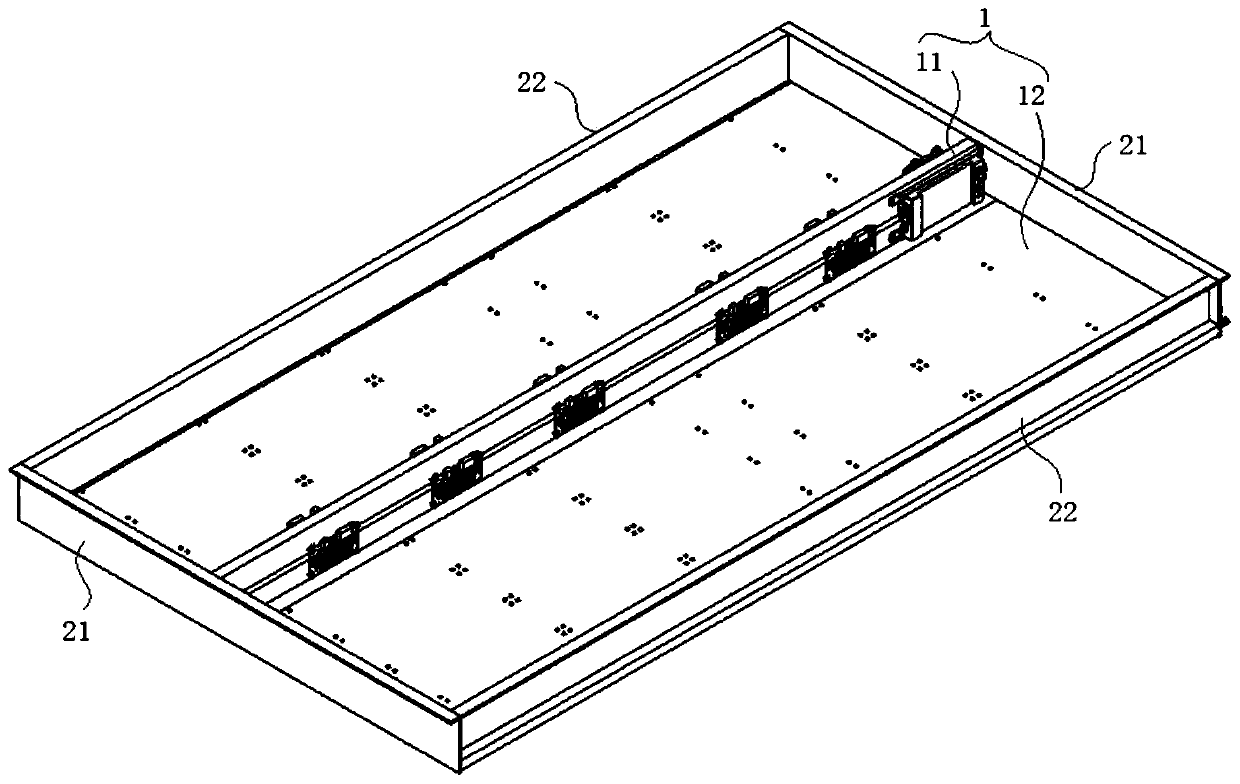

Novel indoor air conditioning wood-plastic plate

InactiveCN104482645ARich choiceHigh acceptanceCovering/liningsLighting and heating apparatusEngineeringIndoor air

The invention provides a novel indoor air conditioning wood-plastic plate. The novel indoor air conditioning wood-plastic plate comprises a wood-plastic plate body, a heat exchange tube and a host machine, wherein a plurality of heat exchange channels are arranged in the wood-plastic plate body, and the heat exchange tube is connected to the host machine through the heat exchange channels to form a circulating pipeline passing through the heat exchange channels; the surface of the wood-plastic plate body is of a three-layer structure, and comprises a plate body, a wood grain layer and a wear-resistant layer from inside to outside. The novel indoor air conditioning wood-plastic plate is efficient and saves energy, heat conduction is achieved from bottom to top, and the requirement of physiological features of a human body is met; due to the fact that wind-free conduction is carried out, sounds are not generated, namely, noise does not exist; the novel indoor air conditioning wood-plastic plate has the function of a floor, and also has the function of heat exchange; the novel indoor air conditioning wood-plastic plate resists moisture and cannot deform at the temperature ranging from 3DEG C to 60DEG C; multiple choices can be provided for customers, customer acceptability is high, quality of the novel indoor air conditioning wood-plastic plate can be effectively improved, and the service life can be prolonged.

Owner:DUYUN NUANDONG WATER HEATING FLOOR

Power cell casing and power cell

InactiveCN110165109AReduce weightReduce volumeSecondary cellsCell component detailsInlet channelWater channel

The invention relates to a power cell casing and a power cell. The power cell casing is used for receiving a cell or a cell unit. The power cell casing is provided with a chamber structure for flowingof heat exchange liquid, wherein the chamber structure includes at least one water inlet channel and at least two water outlet channels extending in a longitudinal direction and multiple cooling water channels extending in a lateral direction, in the lateral direction, one water inlet channel is arranged between two adjacent water outlet channels, a set of heat exchange water channels is arrangedbetween the water inlet channel and the adjacent water outlet channel, each set of heat exchange water channels includes multiple heat exchange water channels, the multiple heat exchange water channels in the same set are in fluid communication in parallel between the water inlet channels and the adjacent water outlet channels, the casing includes a bottom plate used for fixing the cell or the cell unit, at least the water inlet channel and the heat exchange water channels are disposed on the bottom plate, and multiple turbulent structures spaced apart in the longitudinal direction are constructed in the water inlet channels. The power cell casing is advantaged in that the power cell casing can be both lightweight and with the heat exchange function for the single cell or the cell unit.

Owner:CH AUTO TECH CORP CO LTD

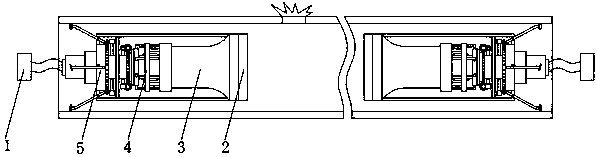

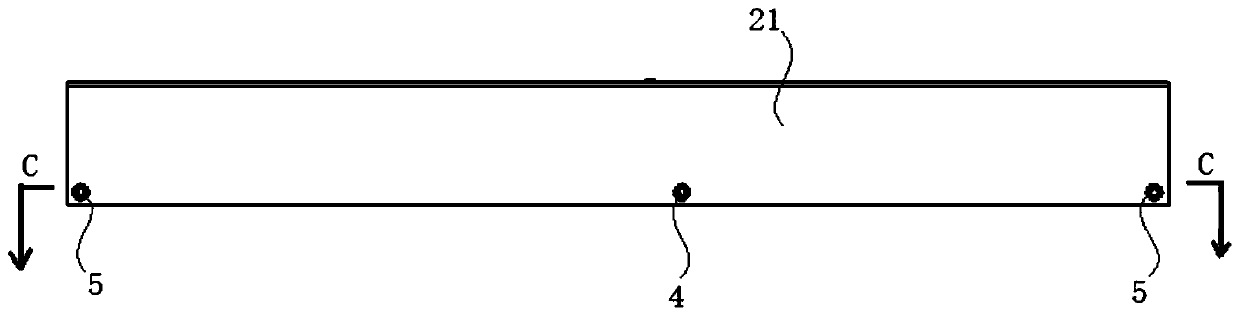

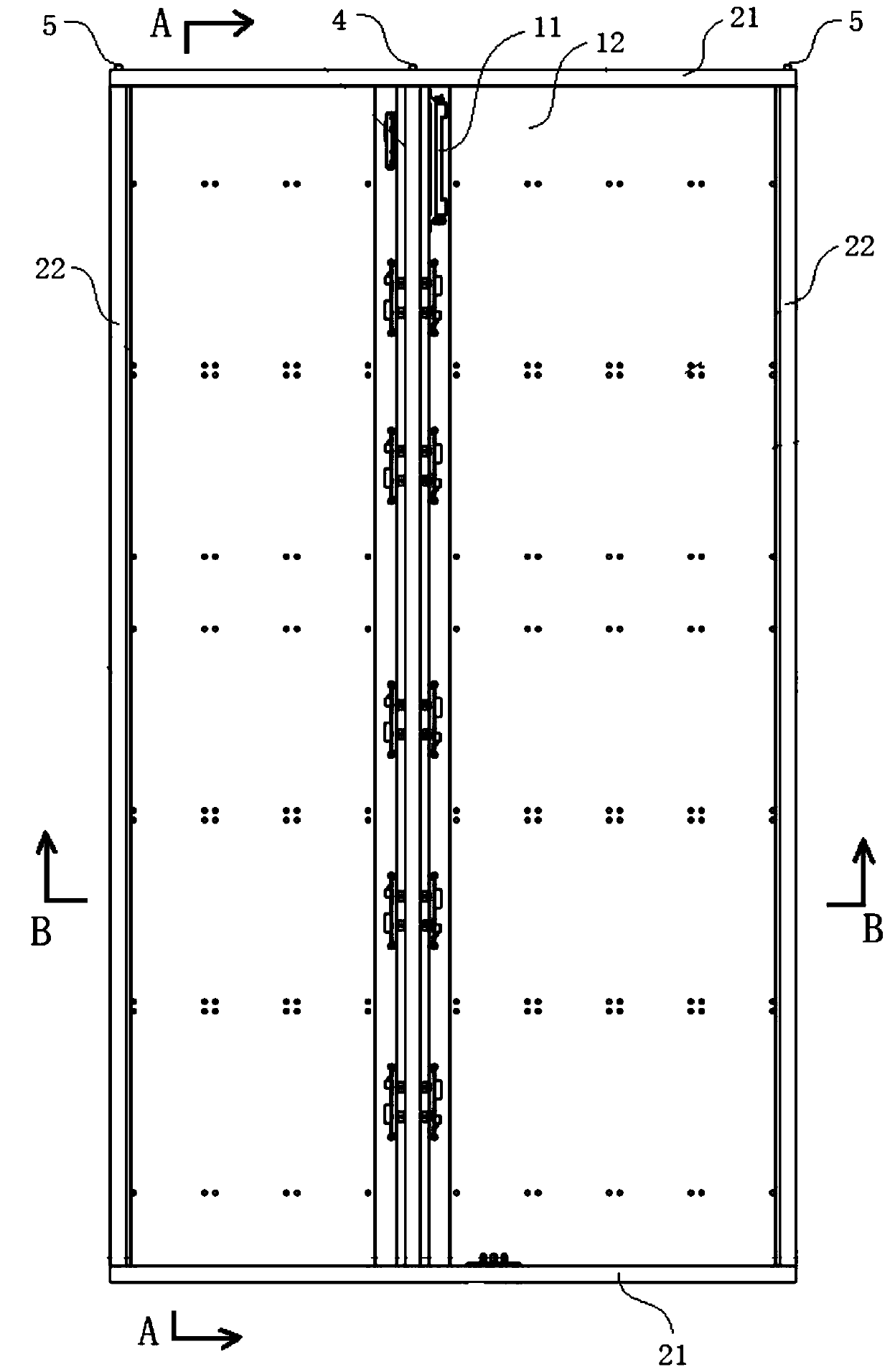

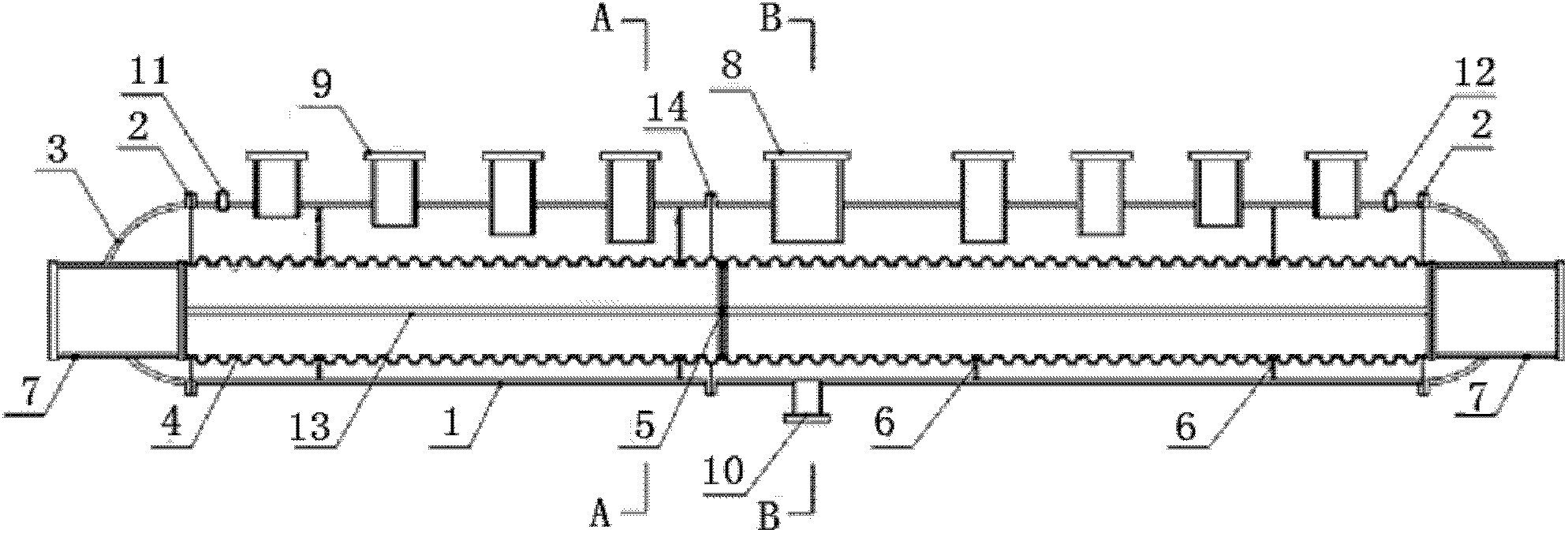

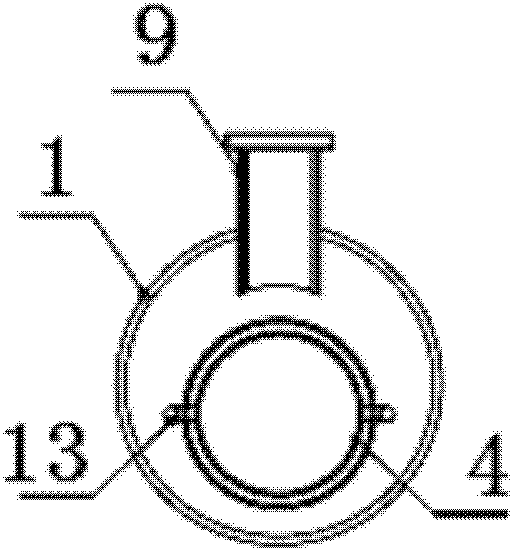

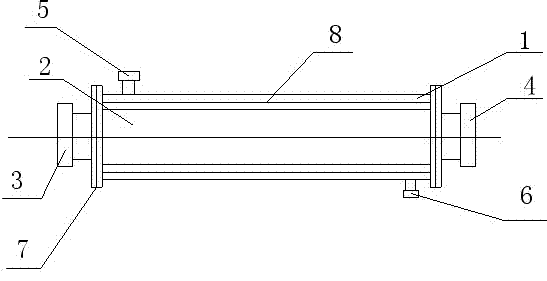

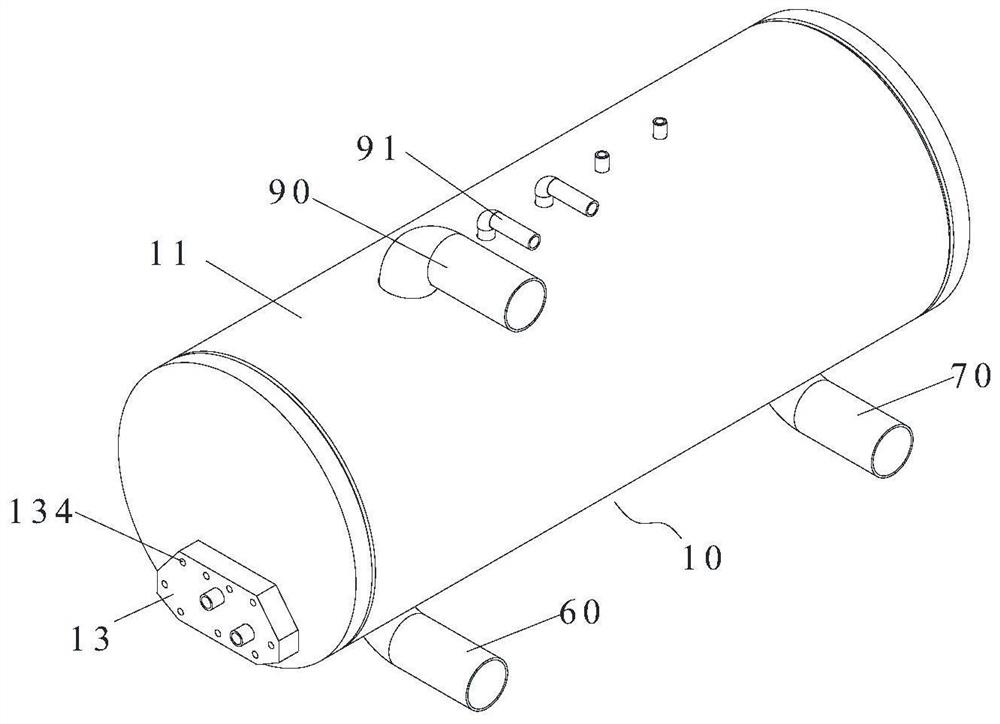

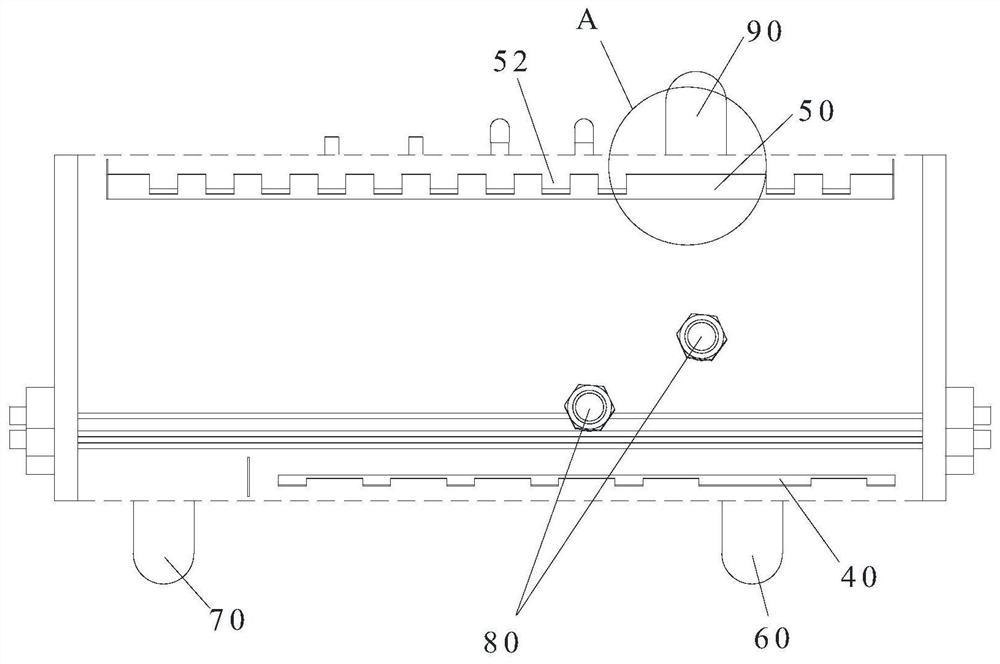

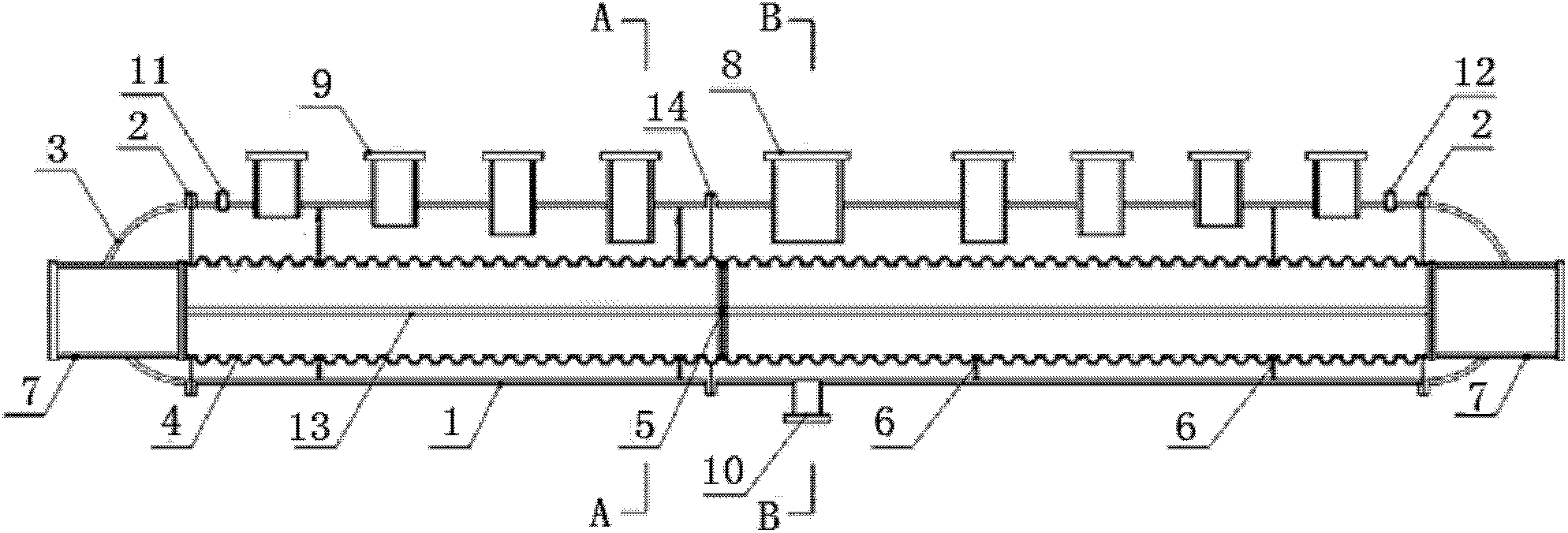

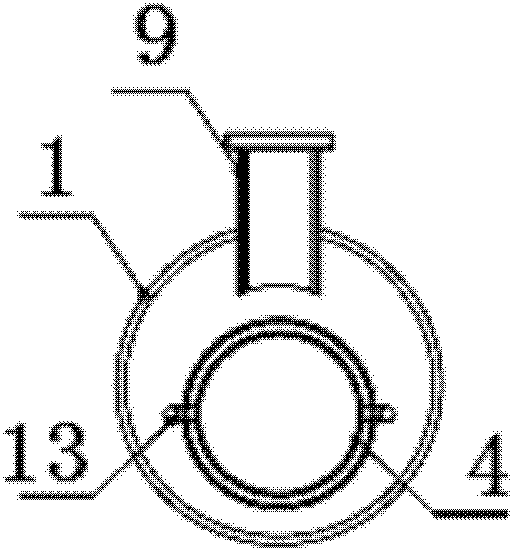

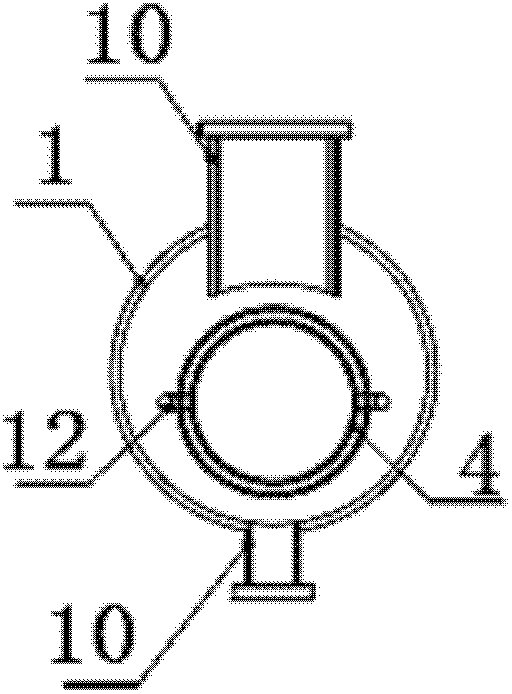

Reinforced convection heat exchange type water distribution and collection device for cold source machine room

ActiveCN102425814AWith heat exchange functionGood value for moneyStationary tubular conduit assembliesHot-water central heatingEngineeringConvection heat

The invention relates to a reinforced convection heat exchange type water distribution and collection device for a cold source machine room. The device comprises a barrel, wherein a first overhauling flange is arranged on the middle part of the barrel, barrel end caps are arranged at two ends of the barrel, second overhauling flanges are arranged at the joints of the barrel and the barrel end caps, a plurality of stainless steel corrugated pipes are arranged in the barrel, the adjacent stainless steel corrugated pipes are connected through a corrugated pipe segmentation flange and a corrugated pipe reinforcing connecting rod, the stainless steel corrugated pipes are fixed with the barrel through a plurality of limiting supports, the stainless steel corrugated pipes positioned at two ends in the barrel are connected with corrugated pipe joints, and the corrugated pipe joints pass through the barrel end caps and are connected with a heat exchange pipeline; and a main water pipe is arranged on the top of the middle part of the barrel, a plurality of branched pipes are uniformly distributed on two sides of the main water pipe, and the main water pipe and the branched pipes extend into the barrel. The device has the advantages of two purposes, high cost performance, good heat exchange effect, low flow resistance, reasonable shunt, space saving and capability of selectively exchanging heat, and is easy and convenient to manufacture, install and maintain.

Owner:CHINA RAILWAY CONSTR GROUP

Detection head movement stabilizing method and leakage point detection method with same

ActiveCN111442567ARealize segmented pressure-holding experimentFind the location of the leakMechanical apparatusClimate change adaptationHead movementsEngineering

Owner:合肥哈罗沃信息科技有限责任公司

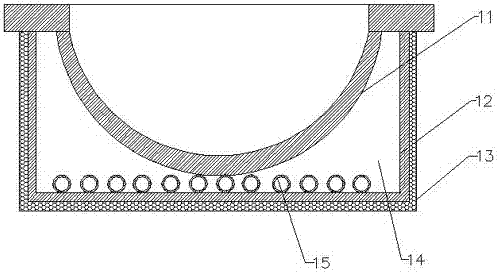

Double-layer heating installation heating and heat exchange bathing device

InactiveCN106931629AImprove insulation effectWith heat exchange functionWater heatersEngineeringThermal water

The invention relates to a double-layer heating installation heating and heat exchange bathing device comprising a tub body; the tub body is composed of an inner tub body and an outer tub body; one end of the tub body is provided with a heating installation hot water inlet pipe and a cold water inlet pipe, and the other end of the tub body is provided with a heat installation hot water outlet pipe and a hot water outlet pipe; a sealed cavity is arranged between the inner tub body and the outer tub body; a tortuous cold water pipe is arranged in the cavity; and two ends of the cold water pipe respectively communicate with the cold water inlet pipe and the hot water outlet pipe. The outer surface of the outer tub body is provided with a heat insulating layer. The double-layer heating installation heating and heat exchange bathing device has the beneficial effects that not only can water in a bath tub be heated, but also the heat insulating effect is good, the water temperature can be conveniently regulated, and the double-layer heating installation heating and heat exchange bathing device also has a heat exchange function and can provide hot water for shower or life.

Owner:周大千

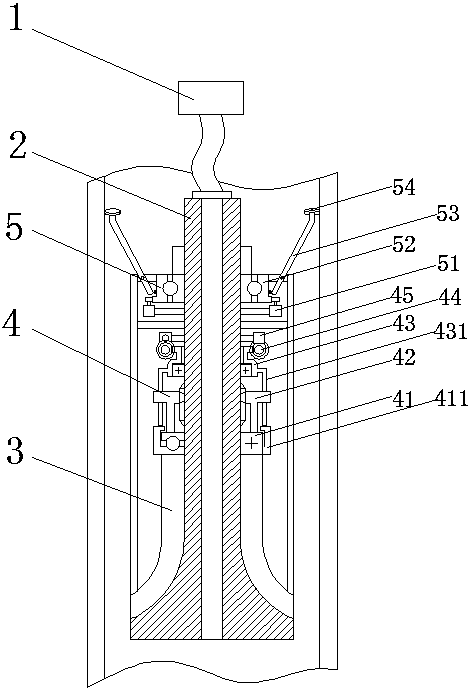

Pipeline repairing device for central air conditioner

ActiveCN108361468ARealize segmented pressure-holding experimentFind the location of the leakPipe elementsPipeline systemsLocking mechanismPersonal computer

The invention relates to the technical field of central air conditioners, in particular to a pipeline repairing device for the central air conditioner. A detection device comprises an industrial personal computer, a detection head, a blocking sleeve pipe, a sleeve pipe expulsion device and a detection head moving device, the detection head is connected with the industrial personal computer througha vacuum pipe, the lower end of the detection head is provided with a blocking sleeve pipe sleeve, the sleeve pipe expulsion device is connected to the middle portion of the detection head in a sleeved manner, the upper end of the detection head is further connected with the detection head moving device in a sleeved manner, the repairing device comprises an elastic sleeve pipe, expansion rings and a locking mechanism, two ends of the elastic sleeve pipe are each provided with one expansion ring, the two expansion rings are both connected inside the elastic sleeve pipe in a sleeved manner, andthe locking mechanism is clamped on the two expansion rings. By means of the pipeline repairing device for the central air conditioner, segmented pressure maintaining test performed on the inner portion of a heat exchanging pipe is realized, so that leakage point positions of the inner portion of the heat exchanging pipe are found out, the two expansion rings are driven by the locking mechanism to fix the elastic sleeve pipe inside the heat exchanging pipe, and repairing on the leakage point positions of the heat exchanging pipe is realized.

Owner:河北纳森空调有限公司

Single ventilation device with heat exhange function

InactiveCN1216257CWith heat exchange functionEnergy recovery in ventilation and heatingHeat recovery systemsThermodynamicsElectric machine

PURPOSE: A single blower system for exchanging heat and ventilating is provided to reduce energy consumption by actively supplying and exhausting air and recovering exhaust heat through heat exchange with the single blower, and to cut down manufacturing cost by reducing the number of parts and noise. CONSTITUTION: A blower system for exchanging heat and ventilating is composed of a chamber case(200) having the divided portions not to mix internal air and external air and flowing internal air and external air in; an internal and external air separation plate(300) inserted to the chamber case to guide and separate external air from internal air; and a single blower(400) exchanging heat and filtering external air and internal air divided and guided by the internal and external air separation plate, and supplying external air indoors and discharging internal air outdoors.

Owner:朴凤泰

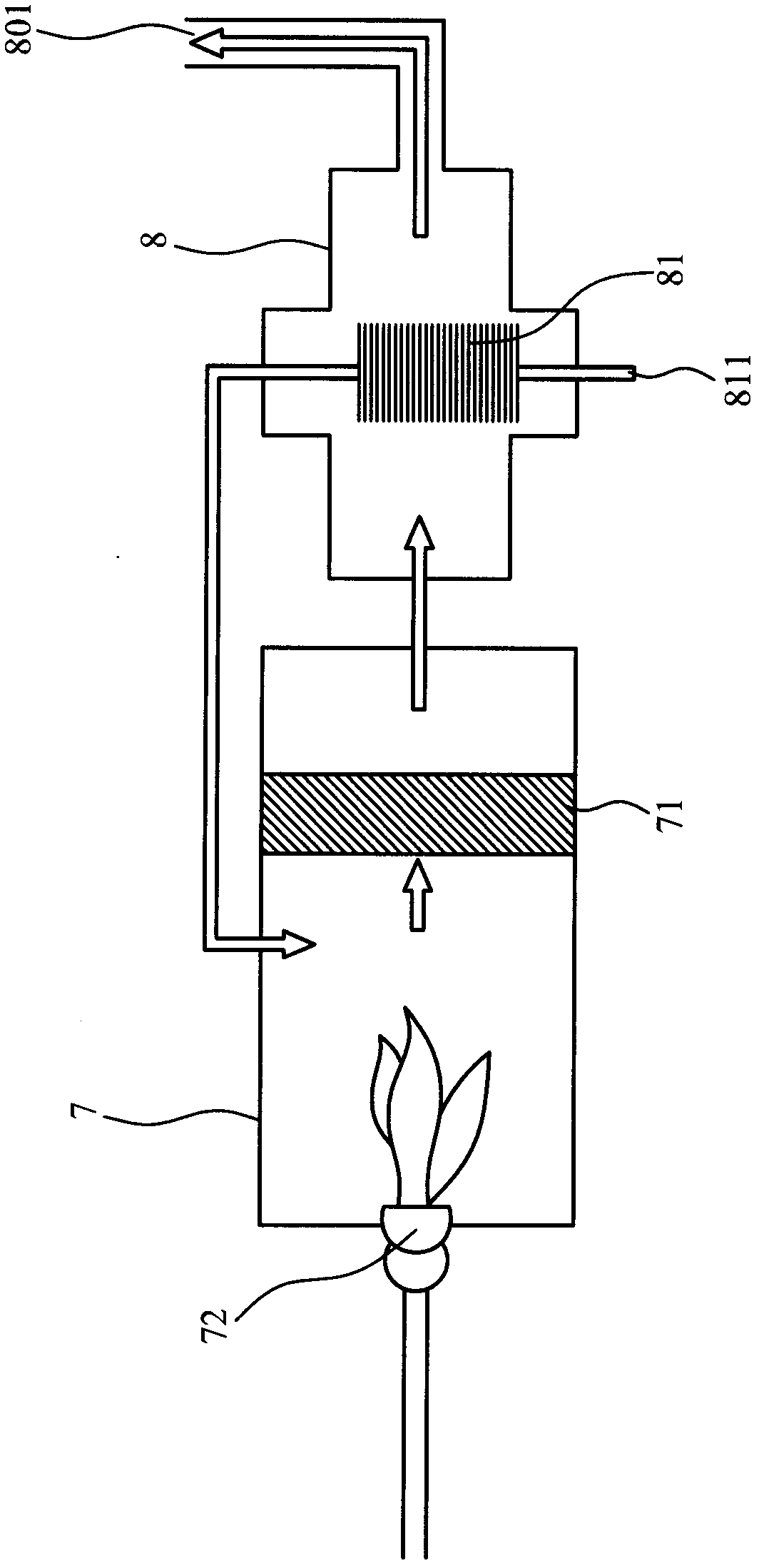

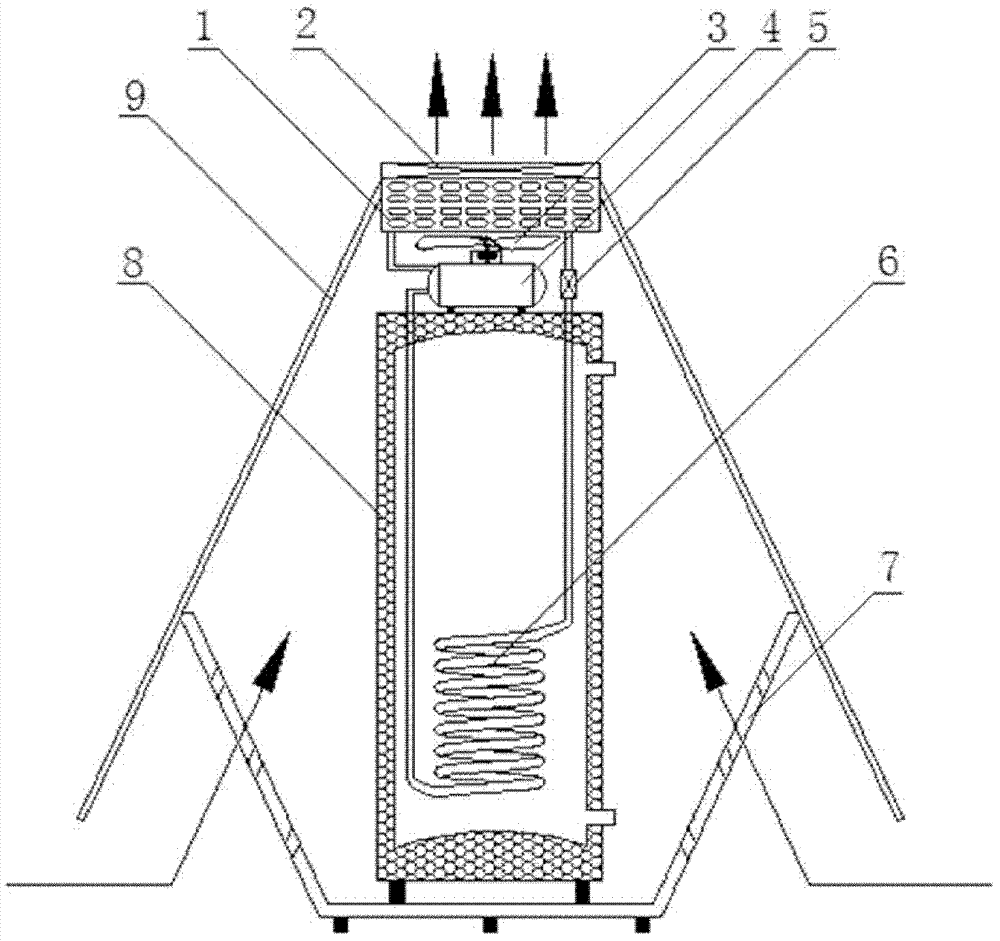

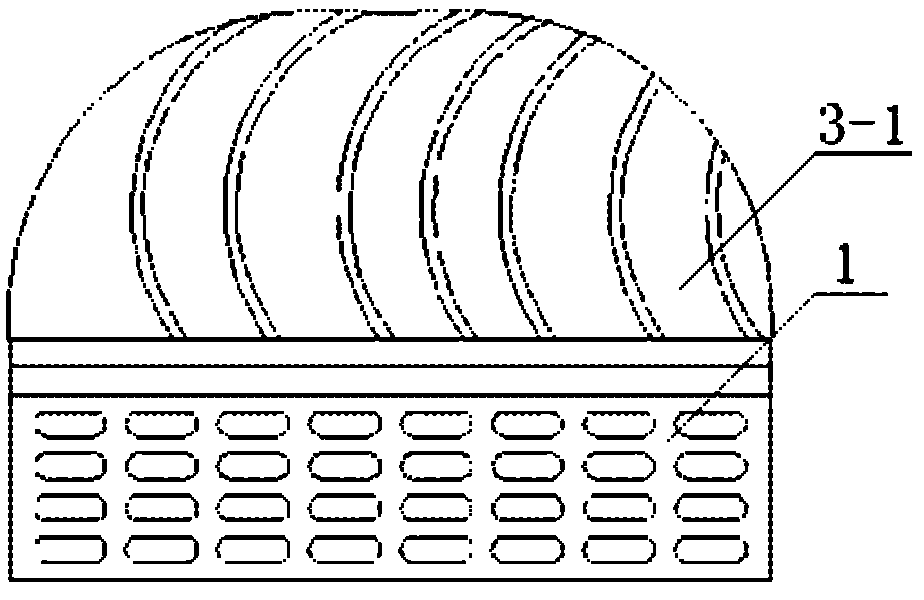

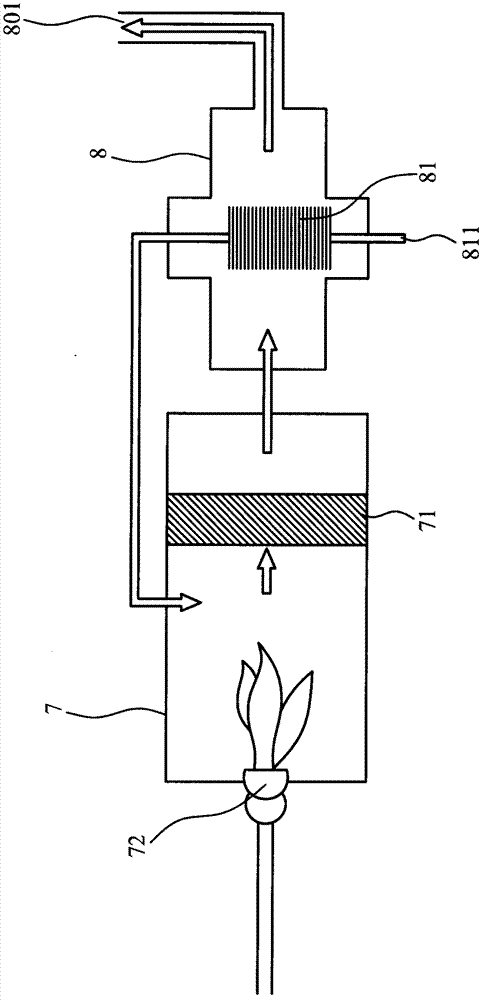

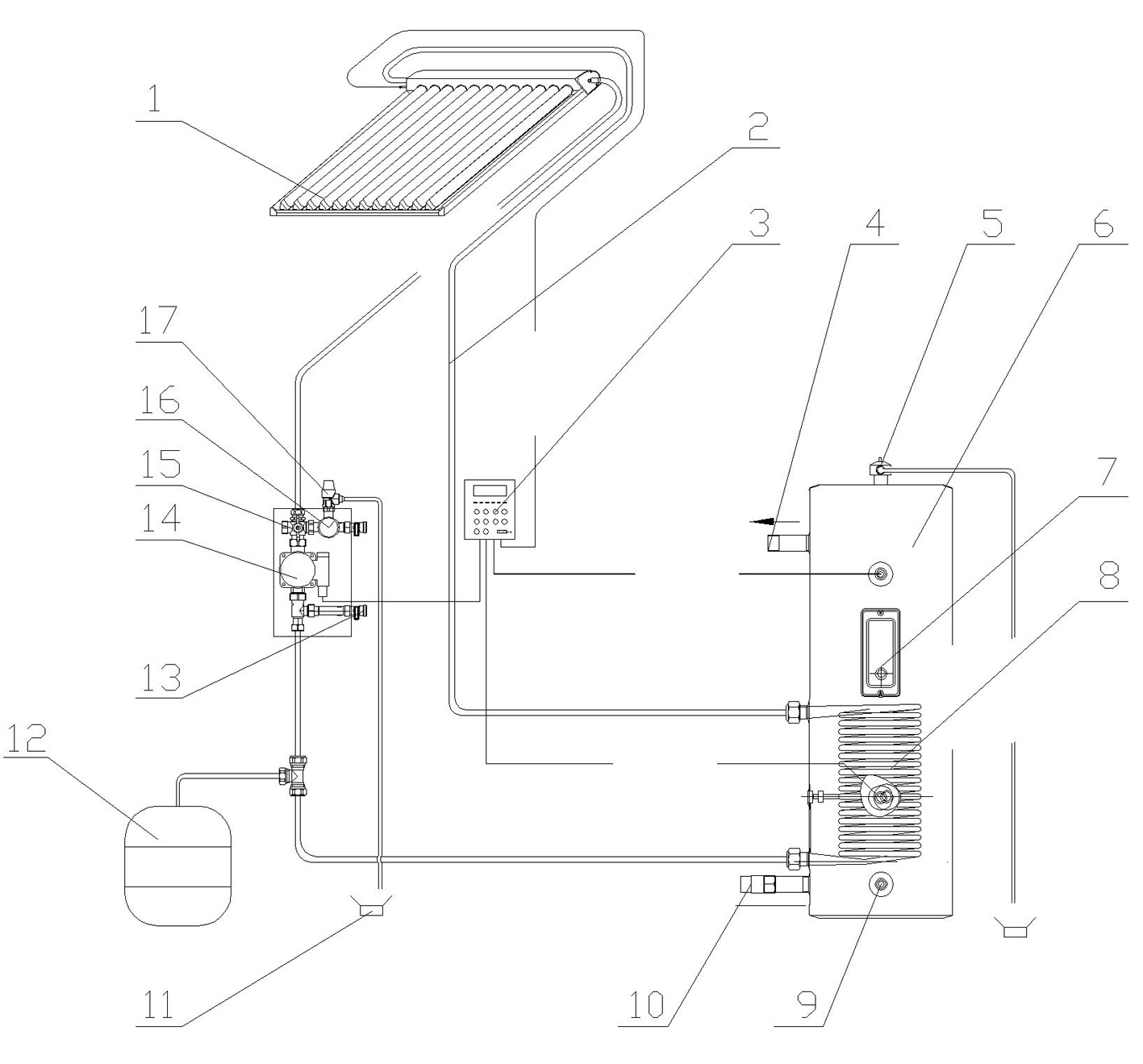

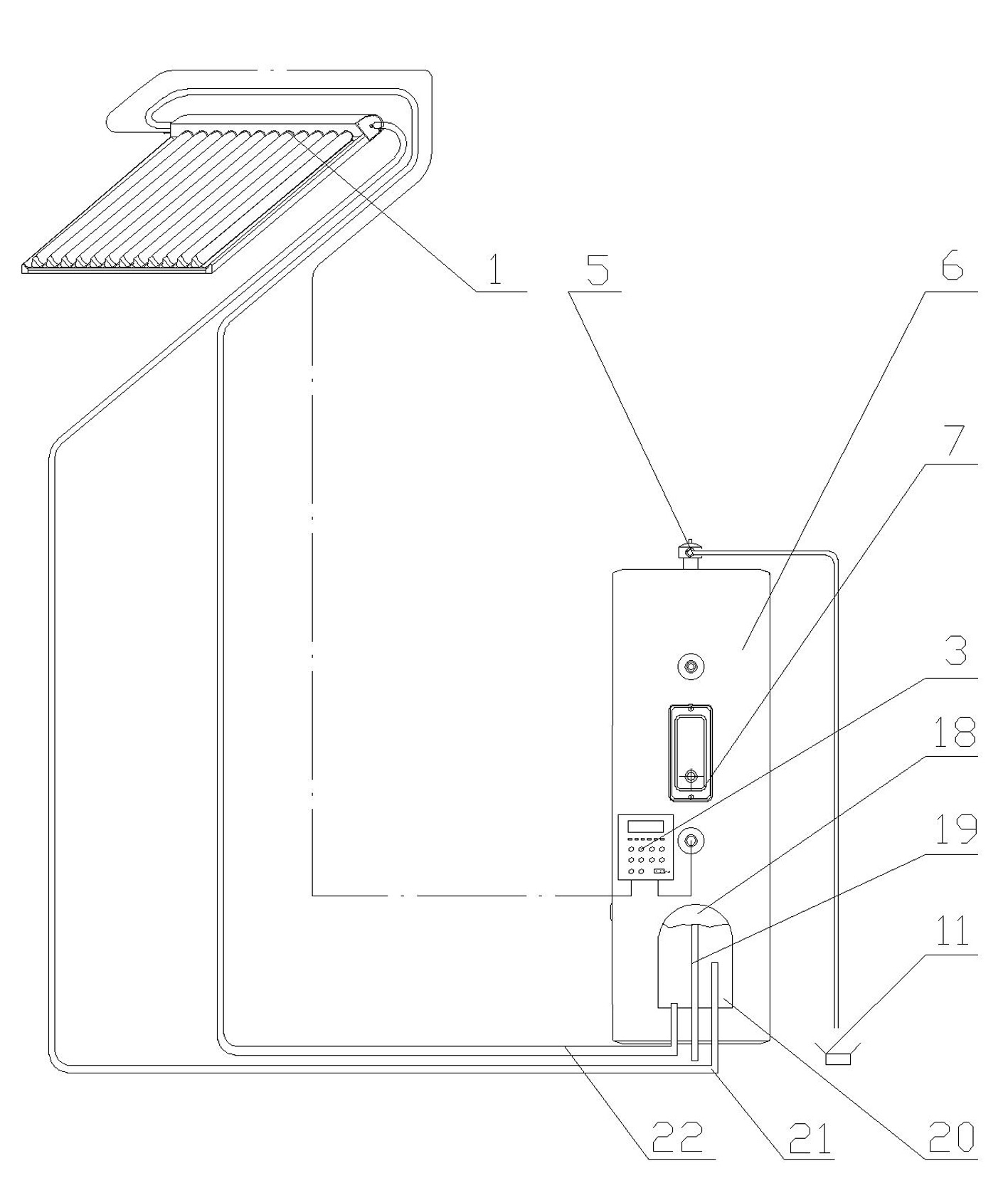

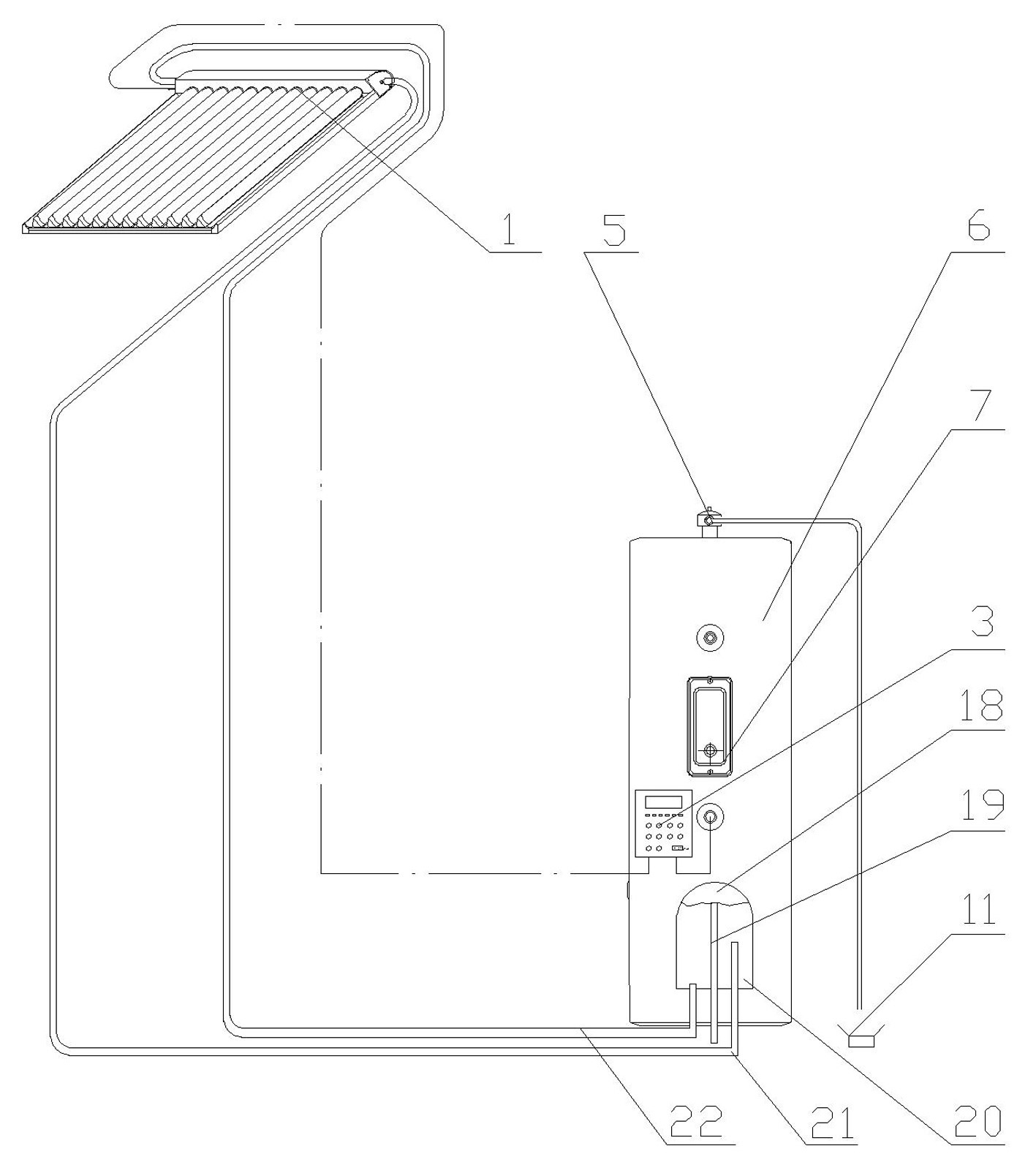

Tower type solar energy heat pump hot water system

InactiveCN102589148BSignificant supercooling functionReduce heat lossSolar heat devicesSolar thermal energy generationRadiation lossEngineering

The invention discloses a tower type solar energy heat pump hot water system comprising a circulating heat exchanging system composed of an evaporator, a compressor, an expansion valve and condenser. The condenser is arranged at the inner part of a water tank and is connected with the evaporator, the compressor and the expansion valve by a pipeline; the evaporator, the compressor and the expansion valve are arranged on the top part of the water tank; the evaporator is connected with heat collection plates; and the heat collection plates are unfolded at the periphery of the evaporator to form a tower type structure to cover the circulating heat exchanging system and the water tank in a tower. In the tower type solar energy heat pump hot water system, the tower type structure formed by the solar energy heat collection plates and the heat pump evaporator through combination is adopted, and the air in the tower is heated through radiation to the inside of the tower by the heat collection plates by absorbing solar energy and heat convection, therefore, the water tank and the compressor can be insulated, external heat dissipation of the water tank can be reduced, overcooling of the compressor can be prevented, radiation loss of the system to the environment is effectively reduced, and the heat efficiency is improved.

Owner:GUANGDONG ZONOPO INTELLIGENT TECH

Graphite pipeline capable of exchanging heat

InactiveCN103090705AHas a heat transfer effectWide corrosion resistanceStationary tubular conduit assembliesHeat exchange apparatusGraphiteMaterials science

The invention discloses a graphite pipeline capable of exchanging heat. The graphite pipeline is characterized by comprising a graphite pipe wall, wherein a thermal fluid pipe is arranged in the graphite pipe wall, a cold fluid inlet and a cold fluid outlet are arranged on the graphite pipe wall, a thermal fluid inlet and a thermal fluid outlet are arranged on the thermal fluid pipe, and graphite bolts are installed at two ends of the graphite pipe wall. The graphite pipeline has the advantages of being reasonable in structure, long in service life and capable of exchanging heat.

Owner:周兵

System and method for increasing comprehensive heat energy utilization rate in hot-process phosphoric acid production process

InactiveCN106369570AAvoid the danger of running too hotSave waterSteam superheatersSteam generation using hot heat carriersCombustionPhosphoric acid

The invention discloses a system and method for increasing the comprehensive heat energy utilization rate in the hot-process phosphoric acid production process, and relates to the field of hot-process phosphoric acid production. The system comprises a reaction tower, an overheater and a hydration tower which are sequentially connected. A plurality of first heat exchange pipes are arranged in the reaction tower, and a steam pocket is arranged outside the reaction tower. The first heat exchange pipes communicate with the steam pocket. After media in the first heat exchange pipes absorb the combustion reaction heat of yellow phosphorus in the reaction tower, a steam and water mixture is formed and enters the steam pocket, steam and water separation is then conducted through the steam pocket, and saturated steam is formed. The overheater is connected with the steam pocket, and the steam pocket inputs the saturated steam into the overheater. The overheater is used for absorbing heat of high-temperature P2O5 smoke discharged by the reaction tower, the saturated steam is heated, overheat steam is formed, and meanwhile low-temperature P2O5 smoke is produced. By means of the system and method, the comprehensive heat energy utilization rate in the hot-process phosphoric acid is effectively increased, meanwhile, consumption of water in the technology is reduced, and water resources are saved.

Owner:WUHAN DONGSHENG JIENENG TECH

A central air-conditioning heat exchange tube leak detection device

ActiveCN108318192BRealize segmented pressure-holding experimentFind the location of the leakMeasurement of fluid loss/gain rateLocking mechanismEngineering

The invention relates to the technical field of central air-conditioning, in particular to a central air-conditioning heat exchange tube leakage point detecting device. The central air-conditioning heat exchange tube leakage point detecting device comprises: an industrial personal computer, a detecting head, a plugging casing pipe, a casing pipe extruding device and a probe moving device; the detecting head is connected to the industrial personal computer through a vacuum tube; the lower end of the detecting head has a plugging casing pipe sleeve; the center of the detecting head is sleeved with the casing pipe extruding device; the probe moving device sleeves the upper end of the detecting head; a repairing device comprises an elastic sleeve, expansion rings and a locking mechanism, wherein each of both ends of the elastic sleeve is provided with an expansion ring, the two expansion rings are sleeved inside the elastic sleeve, and the locking mechanism is clamped on the two expansionrings; segmentation pressure maintaining test of the interior of the heat exchange tube can be achieved, the position of a leak point inside the heat exchange tube can be found; the locking mechanismdrives the two expansion rings to fix the elastic sleeve inside the heat exchange tube, and then the leak point of the heat exchange point is repaired.

Owner:河北纳森空调有限公司

Open double-bucket water dispenser

InactiveCN103006062BWith heat exchange functionGood energy saving effectBeverage vesselsMicrocontrollerPhysical health

Owner:王森

Two-stage heat exchange type cyclone separator

InactiveCN110947530AImprove separation efficiencyWith heat exchange functionReversed direction vortexThermodynamicsEngineering

The invention discloses a two-stage heat exchange type cyclone separator, which has the functions of heat exchange and dust removal at the same time, and a first-stage cyclone separator and a second-stage cyclone separator are selected, wherein fluid directors are arranged in cylindrical sections of the first-stage cyclone separator and the second-stage cyclone separator; the first-stage cyclone separator and the second-stage cyclone separator adopt 360-degree volute type air inlets; and an exhaust port of the first-stage cyclone separator is communicated with an air inlet of the second-stagecyclone separator through a 180-degree volute type pipeline. Heat exchange pipes are coiled on the outer walls of the cylindrical sections of the first-stage cyclone separator and the second-stage cyclone separator, and the rotating direction of the heat exchange pipes is opposite to the airflow direction of the cyclone separators. The cyclone separator not only can improve the separation efficiency and reduce the pressure drop, but also can utilize the waste heat and reduce the energy consumption.

Owner:SHANDONG UNIV OF SCI & TECH

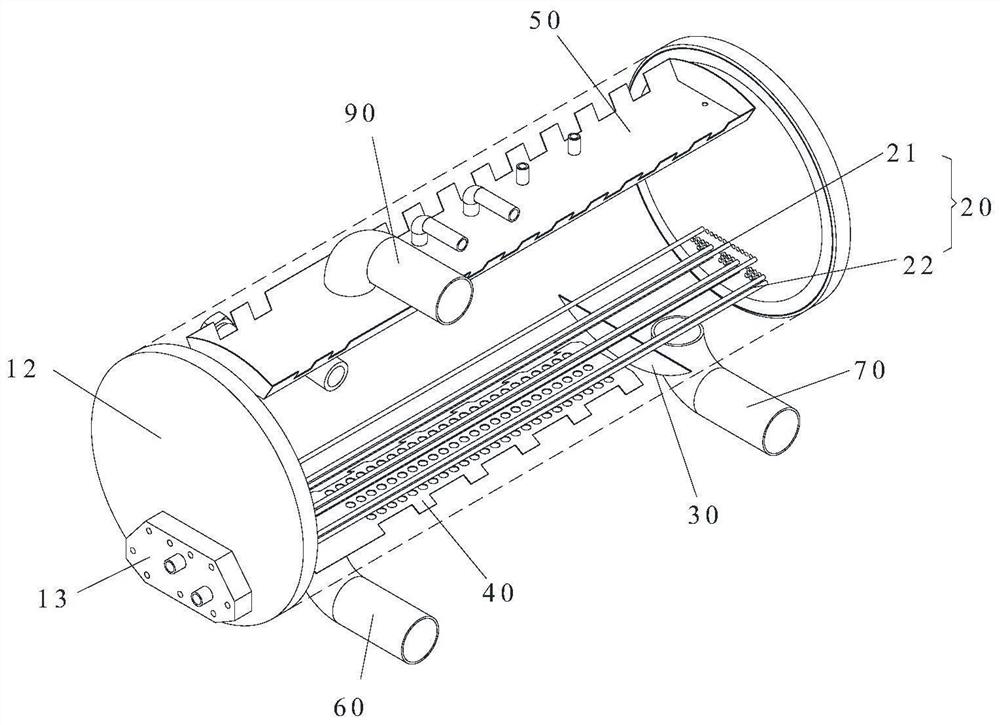

Economizer assembly and refrigerating unit with economizer assembly

ActiveCN111721037ACompact structureEasy maintenanceFluid circulation arrangementCombustion technology mitigationEngineeringMechanical engineering

The invention provides an economizer assembly and a refrigerating unit with the economizer assembly. The economizer assembly comprises an economizer and a heat exchanger, wherein the economizer comprises a cylinder body with a hollow cavity, two tube plates arranged at the two ends of the cylinder body correspondingly, a liquid inlet, a liquid outlet and a main air outlet, the liquid inlet, the liquid outlet and the main air outlet are formed in the cylinder body, the liquid inlet, the liquid outlet and the main air outlet all communicate with the hollow cavity, the heat exchanger comprises aplurality of heat exchange tube bundles arranged at intervals, and the plurality of heat exchange tube bundles are located in the hollow cavity. According to the technical scheme, the problems that inthe prior art, an economizer and a heat exchanger which are arranged in a split mode are large in occupied space and not compact enough in structure, and the heat exchanger cannot be overhauled are solved.

Owner:浙江盾安机电科技有限公司

Depth indication method and leakage point detection method with same

ActiveCN111442566ARealize segmented pressure-holding experimentFind the location of the leakMechanical apparatusEnergy efficient heating/coolingLocking mechanismPhysics

The invention relates to the technical field of central air conditioners, in particular to a depth indication method and a leakage point detection method with the same. A detection device comprises anindustrial personal computer, a detection head, a plugging sleeve, a sleeve extruding device and a detection head moving device, wherein the detection head is connected with the industrial personal computer through a vacuum pipe, the lower end of the detection head is provided with the plugging sleeve, the sleeve extruding device sleeves the middle of the detecting head, and the upper end of thedetection head is also sleeved with the detection head moving device; a repairing device comprises an elastic sleeve, expansion rings and a locking mechanism, wherein the expansion rings are arrangedat the two ends of the elastic sleeve, and the two expansion rings sleeve inside the elastic sleeve, and the locking mechanism is clamped on the two expansion rings; segmentation and pressure-maintaining experiments are carried out on the interior of a heat exchange tube, so that the position of a leakage point inside the heat exchange tube is found out; and the two expansion rings are driven by the locking mechanism to fix the elastic sleeve inside the heat exchange tube, so that the repair at the leakage point of the heat exchange tube is realized.

Owner:ANHUI SHUORI PHOTOELECTRIC TECH

A pipeline repair device for central air-conditioning

ActiveCN108361468BRealize segmented pressure-holding experimentFind the location of the leakPipe elementsPipeline systemsLocking mechanismPersonal computer

Owner:河北纳森空调有限公司

Anti-skid method of leakage point detection device and leakage point detection method with anti-skid method

ActiveCN111442565ARealize segmented pressure-holding experimentFind the location of the leakMechanical apparatusClimate change adaptationLocking mechanismEngineering

The invention relates to the technical field of central air conditioners, in particular to an anti-skid method of a leakage point detection device and a leakage point detection method with the anti-skid method. The detection device comprises an industrial personal computer, a detection head, a plugging sleeve, a sleeve extrusion device and a detection head movement device, wherein the detection head is connected with the industrial personal computer through a vacuum tube, the plugging sleeve is arranged at the lower end of the detection head, the sleeve extrusion device sleeves the middle of the detection head, and the upper end of the detection head is further sleeved with the detection head movement device; a repairing device comprises an elastic sleeve, expansion rings and a locking mechanism, the two ends of the elastic sleeve are each provided with one expansion ring, the two expansion rings are connected into the elastic sleeve in a sleeved mode, and the locking mechanism is clamped on the two expansion rings; a segmented pressure maintaining experiment is carried out on the interior of a heat exchange tube, so that a leakage point position in the heat exchange tube is foundout; and the two expansion rings are driven by the locking mechanism to fix the elastic sleeve in the heat exchange tube, so that the leakage point of the heat exchange tube is repaired.

Owner:合肥哈罗沃信息科技有限责任公司

Trash rack with heat exchange function

ActiveCN107794894BWith heat exchange functionFunctionalWater cleaningArtificial water canalsWater levelMechanical engineering

The invention relates to a trash rack with a heat exchanging function. The trash rack with the heat exchanging function comprises two parallel vertical frames and an S-shaped heat exchanging tube, theS-shaped heat exchanging tube comprises a plurality of upper U-shaped tubes with openings facing downwards, a plurality of lower U-shaped tubes with openings facing upwards and corrugated tubes, thelower U-shaped tubes and the upper U-shaped tubes are arranged in a staggered mode, and the corrugated tubes are used for communicating the upper U-shaped tubes with the lower U-shaped tubes to enablethe whole S-shaped heat exchanging tube to be in an S shape; the upper U-shaped tubes are fixed to an upper tube frame which is slidably connected with the vertical frames, the upper end of the uppertube frame is provided with a floating body, the lower U-shaped tubes are fixed to a lower tube frame, and the lower tube frame is fixedly connected with the vertical frames; and the two upper U-shaped tubes on the outermost sides communicate with a water inlet tube and a water outlet tube through one corrugated tube correspondingly. The trash rack with the heat exchanging function has functionsof trashing holding and heat exchanging; and in addition, the height of the S-shaped heat exchanging tube can be adjusted with the water level, so that the high heat exchanging efficiency is ensured.

Owner:HUNAN ZHONGDA JINGWEI GEOTHERMY DEV TECH CO LTD

Catalytic thermal oxidizer with sintering prevention function and sintering prevention method thereof

ActiveCN102840590BPrevent sinteringSo as not to damageIncinerator apparatusHeat flowProcess engineering

The invention relates to a catalytic thermal oxidizer with sintering prevention function and a sintering prevention method thereof. The catalytic thermal oxidizer comprises a first heat exchanger, a heater and a catalyst bed with entrance and exit, wherein a plurality of cooling devices are arranged in the catalyst bed; a second heat exchanger arranged before the first heat exchanger, wherein a heat flow pipeline is connected between the second heat exchanger and each cooling device of the catalyst bed; a cooling liquid supply and transport device, wherein a cold flow pipeline is connected among the second heat exchanger, the cooling liquid supply and transport device and each cooling device of the catalyst bed; and a controller with a temperature sensor, wherein the temperature sensor is arranged on the exit of the catalyst bed to sense wherein the temperature on the exit exceeds the preset temperature or not, furthermore the start and stop of the cooling liquid supply and transport device is controlled by the controller, so as to automatically reduce the temperature of the catalyst bed and prevent sintering.

Owner:DESICCANT TECH CORP

Reinforced convection heat exchange type water distribution and collection device for cold source machine room

ActiveCN102425814BWith heat exchange functionGood value for moneyStationary tubular conduit assembliesHot-water central heatingInsertion stentEngineering

The invention relates to a reinforced convection heat exchange type water distribution and collection device for a cold source machine room. The device comprises a barrel, wherein a first overhauling flange is arranged on the middle part of the barrel, barrel end caps are arranged at two ends of the barrel, second overhauling flanges are arranged at the joints of the barrel and the barrel end caps, a plurality of stainless steel corrugated pipes are arranged in the barrel, the adjacent stainless steel corrugated pipes are connected through a corrugated pipe segmentation flange and a corrugated pipe reinforcing connecting rod, the stainless steel corrugated pipes are fixed with the barrel through a plurality of limiting supports, the stainless steel corrugated pipes positioned at two ends in the barrel are connected with corrugated pipe joints, and the corrugated pipe joints pass through the barrel end caps and are connected with a heat exchange pipeline; and a main water pipe is arranged on the top of the middle part of the barrel, a plurality of branched pipes are uniformly distributed on two sides of the main water pipe, and the main water pipe and the branched pipes extend into the barrel. The device has the advantages of two purposes, high cost performance, good heat exchange effect, low flow resistance, reasonable shunt, space saving and capability of selectively exchanging heat, and is easy and convenient to manufacture, install and maintain.

Owner:CHINA RAILWAY CONSTR GROUP

Split solar power system

InactiveCN102032686ASimple structureReduce manufacturing costSolar heating energySolar heat devicesEngineeringSolar power

The invention discloses a split solar power system, which comprises a heat collector, a water tank in which a heat exchange part is arranged, and a circulation loop connected with the heat collector and the heat exchange part, wherein the heat exchange part is a small liner with a fin; the small liner is also provided with an exhaust pipe which extends out of the water tank and is provided with a safety valve in the vertical direction; and expansion space is reserved in the small liner. The split solar power system is compact in structure, low in cost and post maintenance cost.

Owner:SHANDONG LINUO PARADIGMA

Air conditioner pipeline repairing method without replacing pipes

ActiveCN108361470ARealize segmented pressure-holding experimentFind the location of the leakPigs/molesLocking mechanismPersonal computer

The invention relates to the technical field of central air conditioners, in particular to an air conditioner pipeline repairing method without replacing pipes. A detection device comprises an industrial personal computer, a detection head, a blocking sleeve pipe, a sleeve pipe expulsion device and a detection head moving device, the detection head is connected with the industrial personal computer through a vacuum pipe, the lower end of the detection head is provided with a blocking sleeve pipe sleeve, the sleeve pipe expulsion device is connected to the middle portion of the detection head in a sleeved manner, the upper end of the detection head is further connected with the detection head moving device in a sleeved manner, the repairing device comprises an elastic sleeve pipe, expansionrings and a locking mechanism, two ends of the elastic sleeve pipe are each provided with one expansion ring, the two expansion rings are both connected inside the elastic sleeve pipe in a sleeved manner, and the locking mechanism is clamped on the two expansion rings. By means of the air conditioner pipeline repairing method without replacing the pipes, segmented pressure maintaining test performed on the inner portion of a heat exchanging pipe is realized, so that leakage point positions of the inner portion of the heat exchanging pipe are found out, the two expansion rings are driven by the locking mechanism to fix the elastic sleeve pipe inside the heat exchanging pipe, and repairing on the leakage point positions of the heat exchanging pipe is realized.

Owner:杨仲辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com