Device and method for measuring wax melting rate and recovery ratio of wax remover under pressure

A wax remover and wax melting technology, which is applied in the field of devices for measuring the wax melting rate and recovery ratio of the wax remover under pressure, and can solve the problems of the experimental device that cannot measure the phase state and easily changes the wax removal rate and recovery rate of the reagent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below with reference to the accompanying drawings and examples.

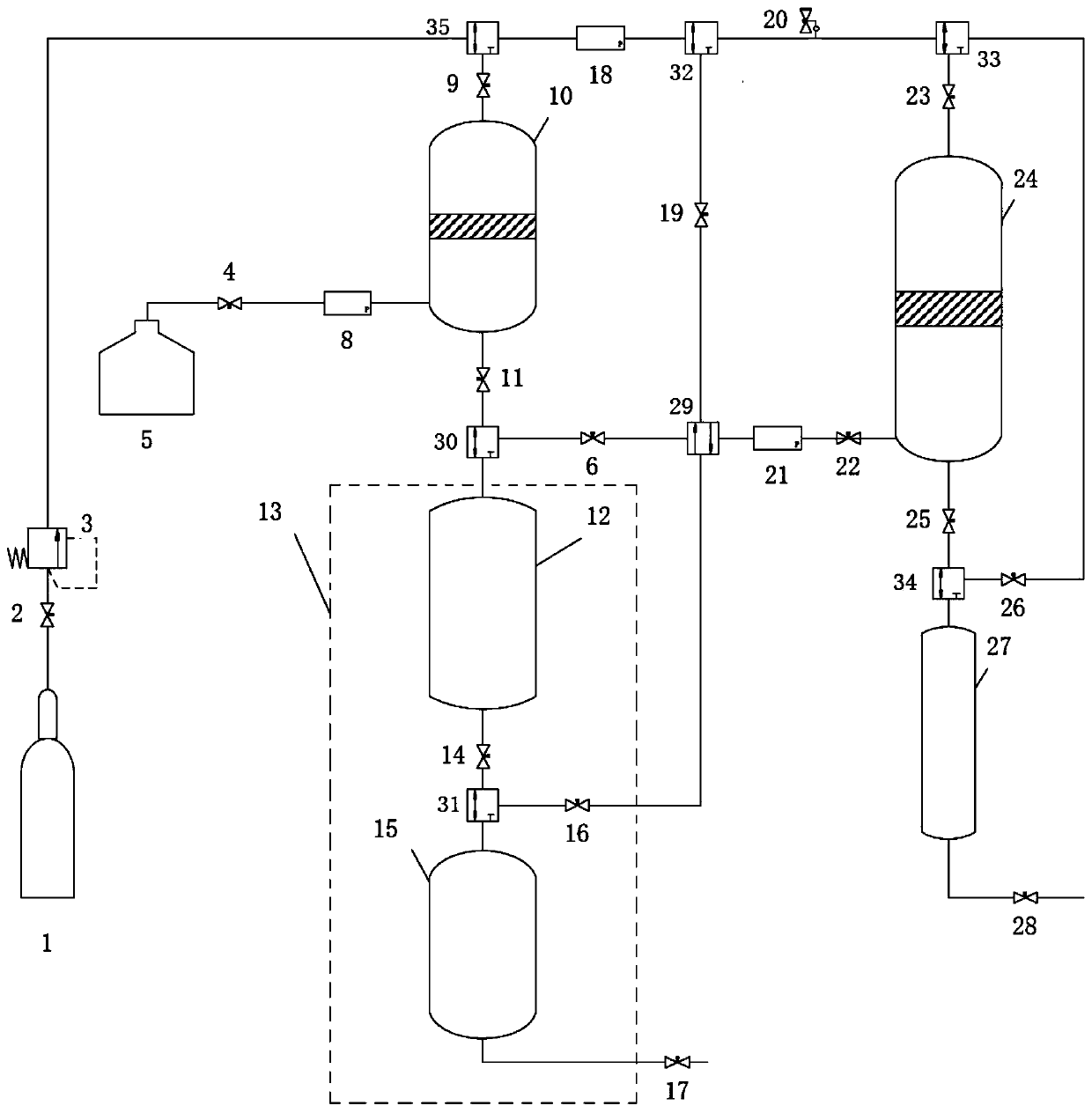

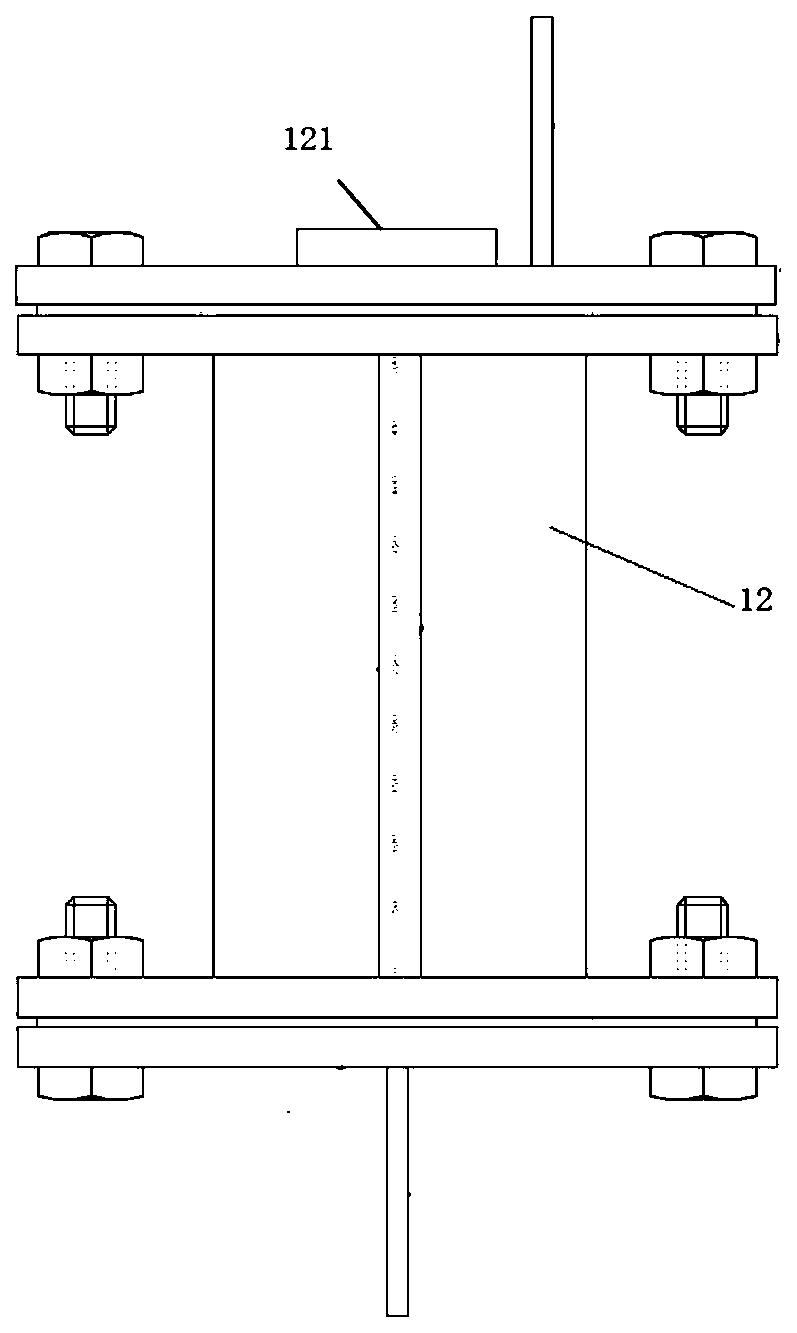

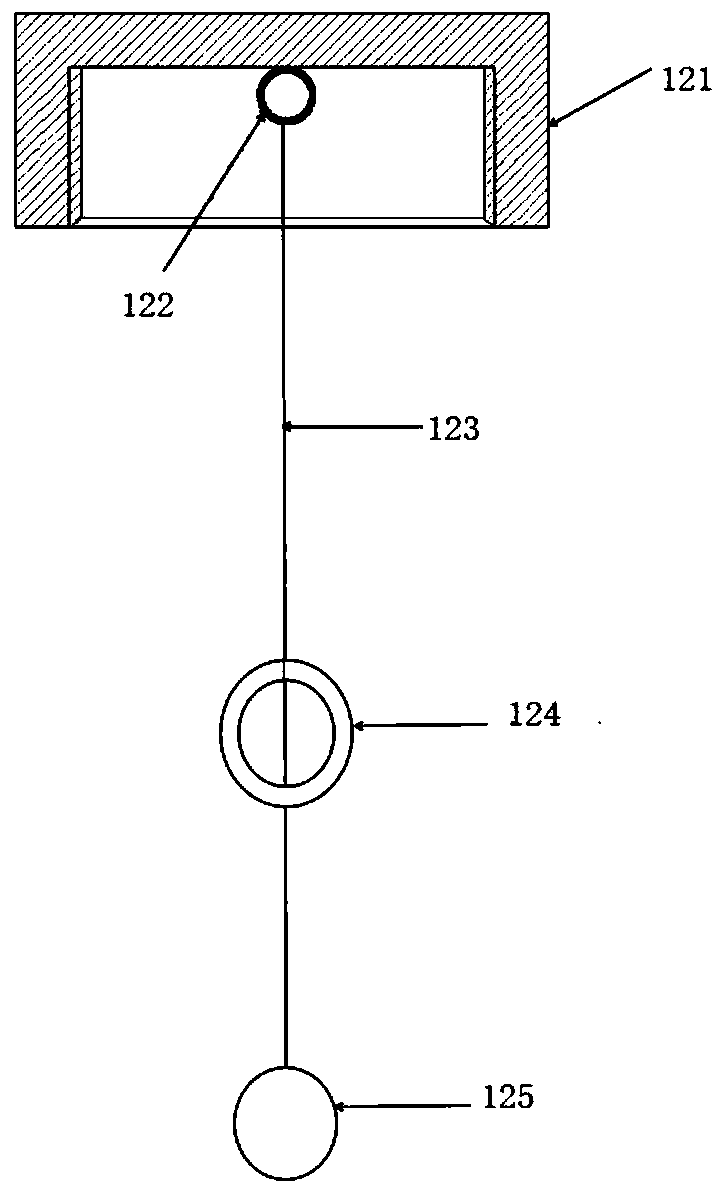

[0051] Such as figure 1As shown, the device for measuring the wax melting rate and recovery ratio of the wax remover under pressure includes a wax melting reactor 12, a piston container A10, a piston container B24, and a recovery tank 15;

[0052] The upper part of the wax melting reactor 12 is connected with the tee A30, and the tee A30 is connected with the lower part of the piston container A10 through the needle valve O11. Connected with the lower part of the piston container B24;

[0053] The lower part of the wax melting reactor 12 is connected to the recovery tank 15 through the needle valve C14 and the tee B31 in turn;

[0054] The top of the piston container A10, the top of the piston container B24, the wax melting reactor 12, the recovery tank 15, and the top of the metering tank 27 are respectively connected to the nitrogen cylinder 1;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com