Trapping efficiency and resistance detection device for filter membrane/filter cartridge

A collection efficiency, detection device technology, applied in the direction of measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of uncomfortable detection, affecting detection results, large volume and noise, etc., to improve the use of Efficiency, protection of personal safety, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

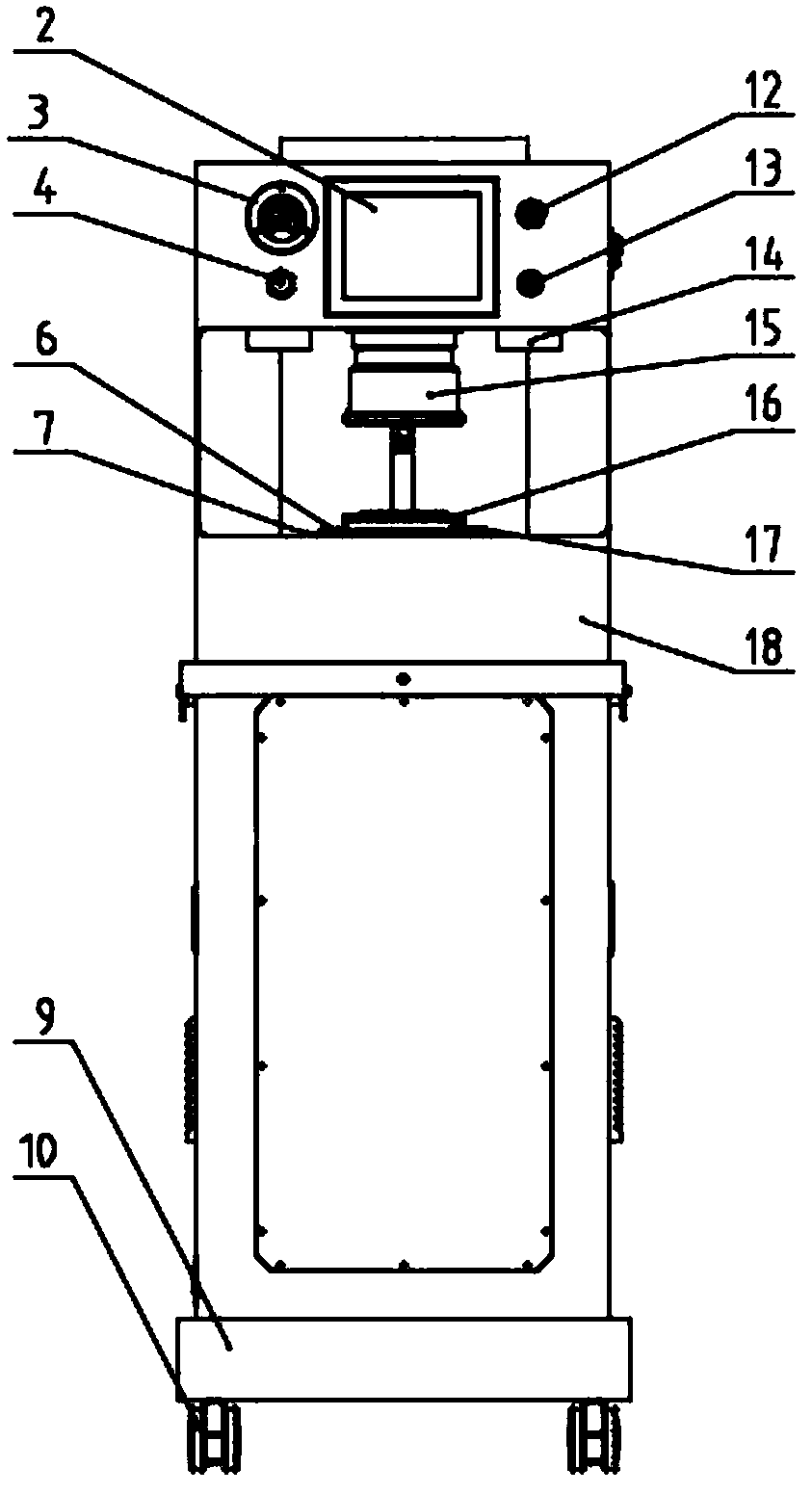

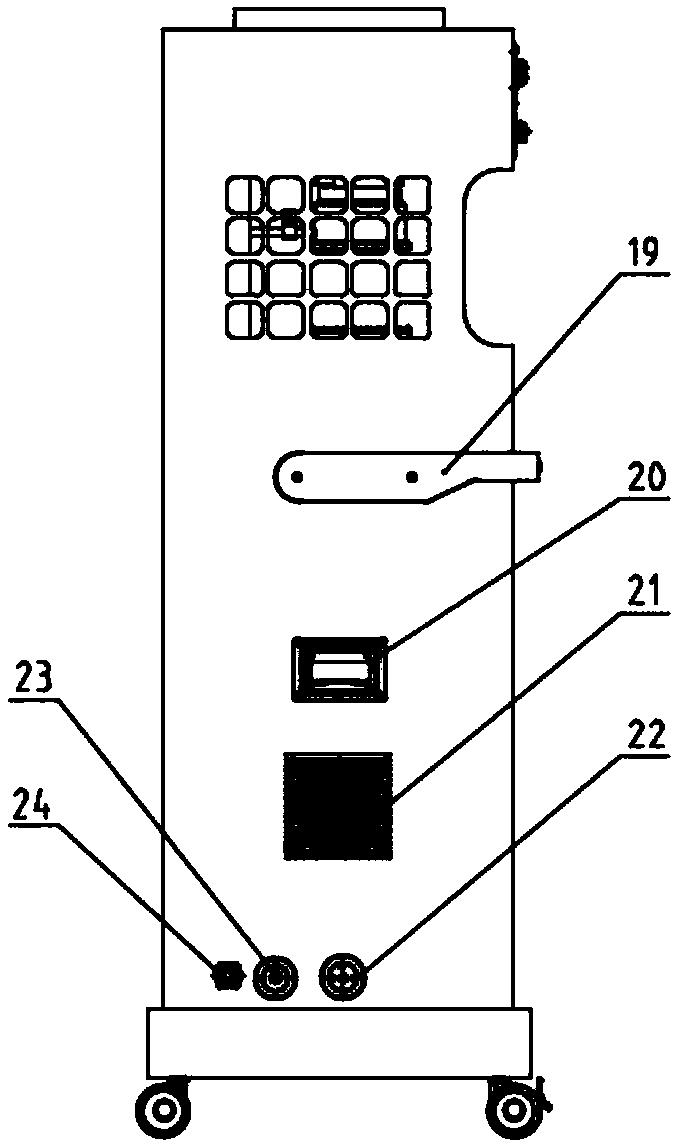

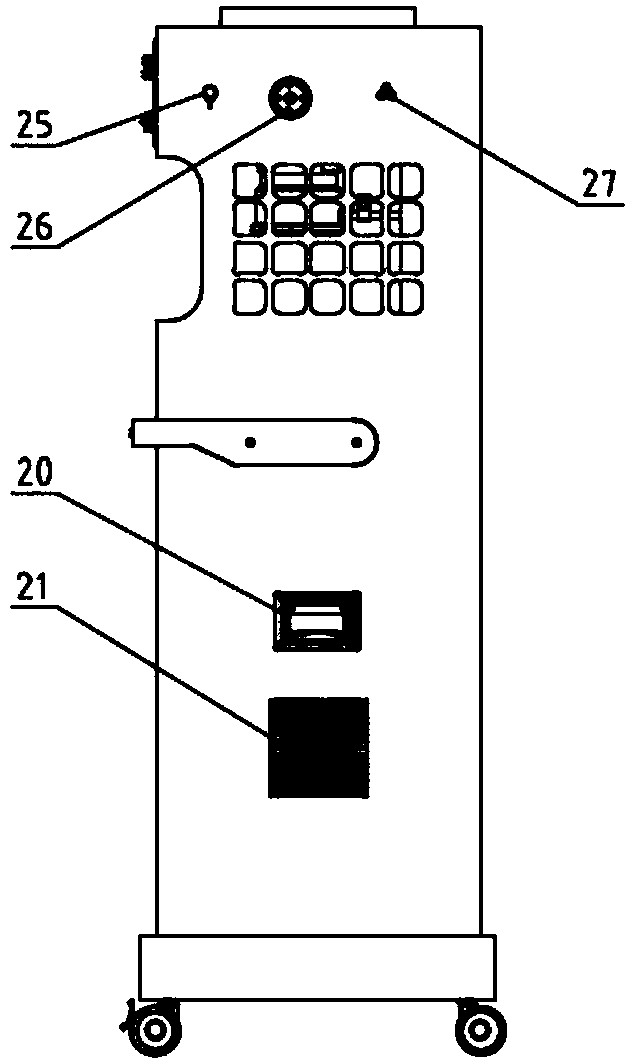

[0030] Such as figure 1 , figure 2 and image 3 As shown, the filter membrane / filter cartridge collection efficiency and resistance detection device of the present invention includes a main housing 18, a base 9 is installed on the bottom of the main housing 18, and a universal wheel 10 is provided on the bottom of the base 9. The upper part of the front side panel of the main housing 18 is provided with a display screen 2, a pressure gauge 3, a USB interface 4, an emergency stop button 12 and a power switch 13, wherein the display screen 2 is located in the middle, and the pressure gauge 3 and USB interface 4 are located at the display screen. 2, the emergency stop button 12 and the power switch 13 are located on the right side of the display screen. The pressure gauge 3 is used for real-time monitoring of the pressure in the pipeline. The emergenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com