Infrared thermal imaging camera non-uniform correction baffle test method for temperature-variable radiation materials

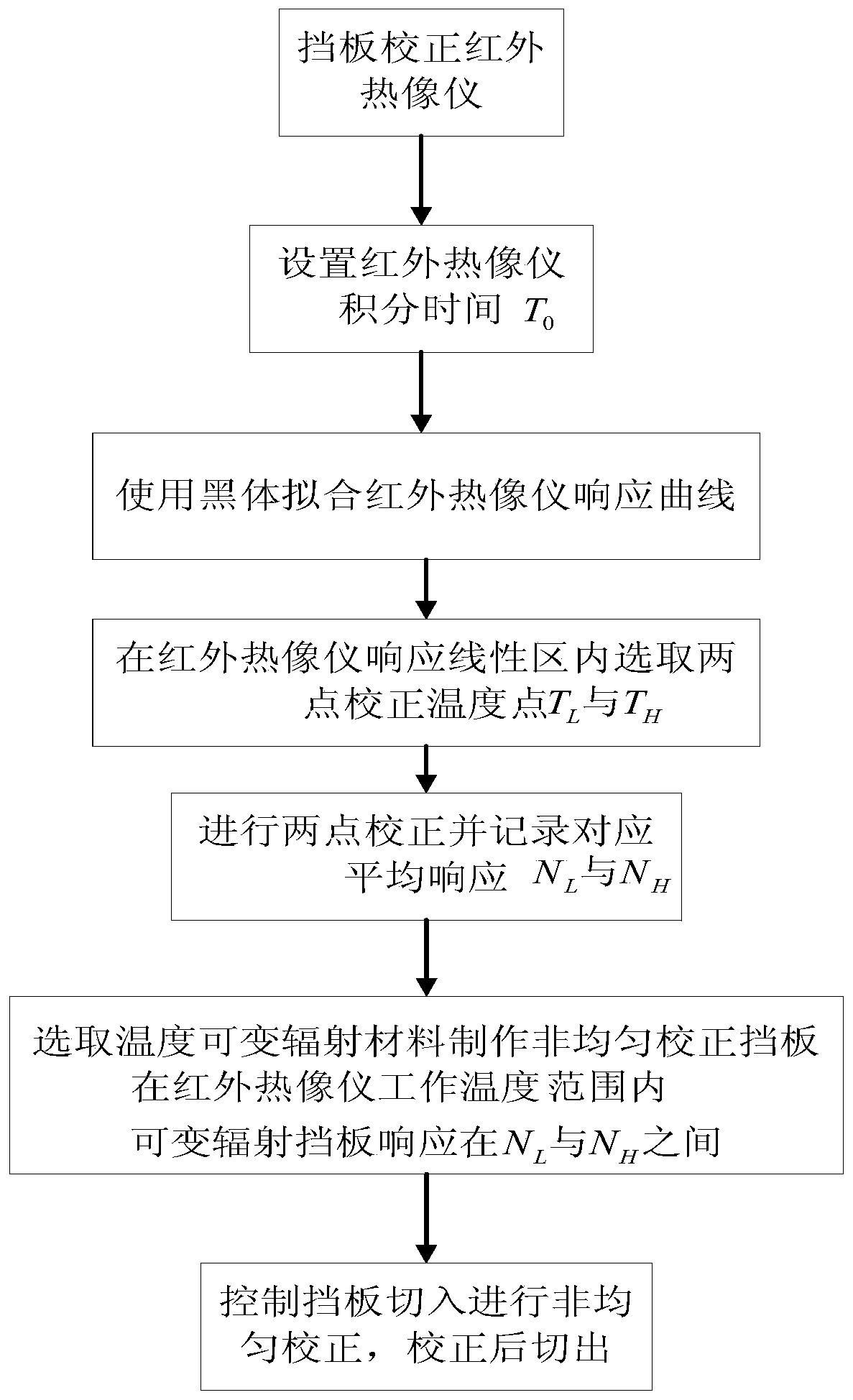

An infrared thermal imager and non-uniform correction technology, which is applied in image communication, television, electrical components, etc., can solve the problem of poor imaging effect of non-uniform correction, achieve the elimination of non-uniformity, improve imaging quality, and eliminate image non-uniformity. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0030] The present invention consists of an infrared imaging component (including an infrared detector), a measured non-uniform correction baffle, an optical system, etc., to form an infrared thermal imager. The infrared thermal imager uses a medium-wave 640×512 area array F4 detector, and the specific implementation steps are as follows:

[0031] Step 1: According to the F number of the detector, determine the actual integration time of the infrared camera to be 12ms;

[0032] Step 2: Under the condition that the integration time is 12ms, the infrared thermal imager collects temperature points against the blackbody. It is required that the blackbody target surface completely covers the infrared thermal imager field of view, and the distance between the infrared thermal imager and the blackbody target surface is not greater than 200mm. This distance was kept cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com