Method of producing organic light emitting apparatus

An organic light-emitting device and a technology for organic light-emitting devices, which are used in electroluminescent light sources, semiconductor/solid-state device manufacturing, light sources, etc. Excellent drive durability characteristics, excellent placement durability characteristics, effect of non-uniformity elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

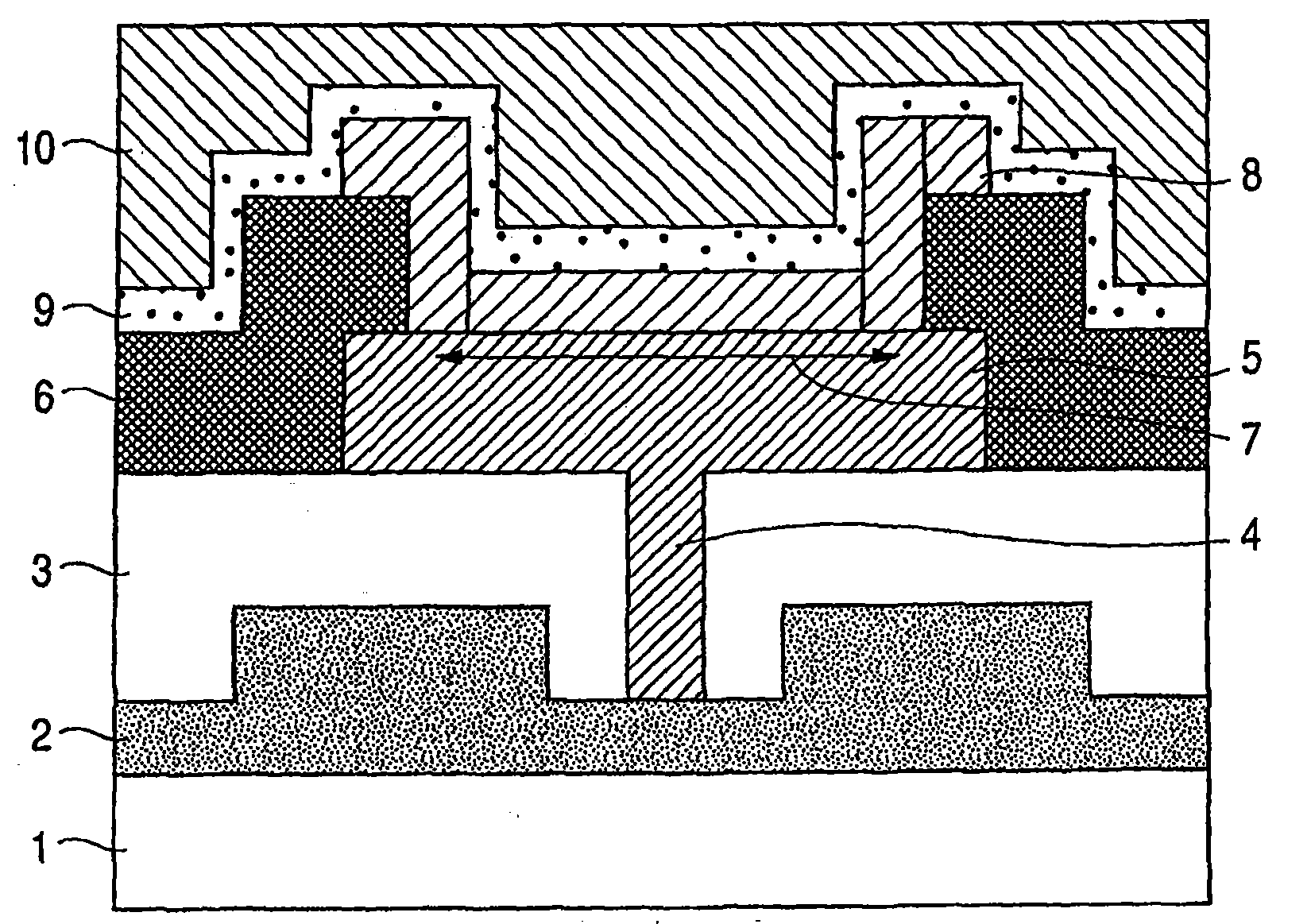

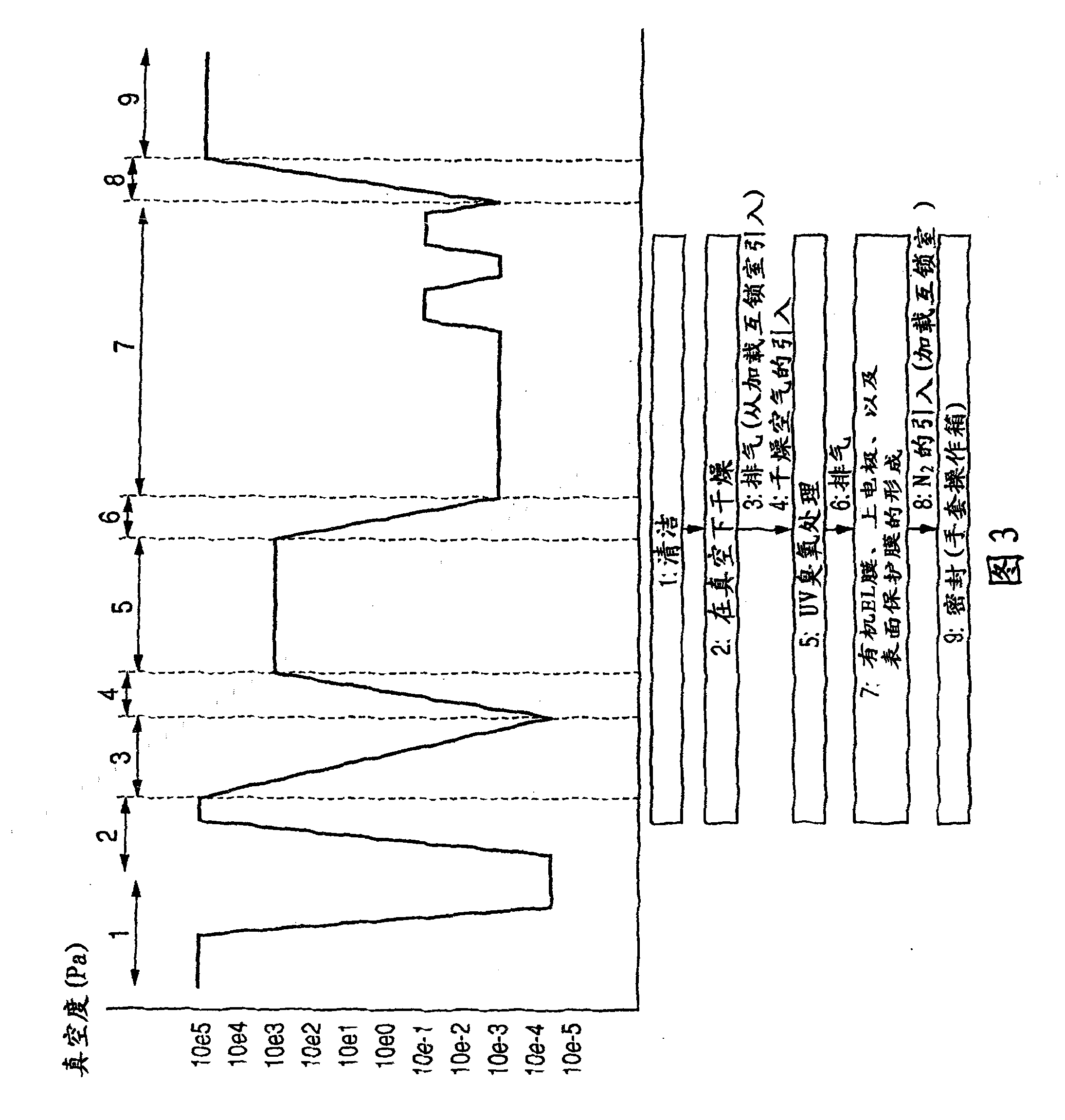

[0052] Using a positive photoresist polyimide resin, a device separation film with a thickness of 2 μm was formed over the entire surface of a substrate on which ITO formed on an Ag alloy film (thickness: 100 nm) was provided The film (thickness: 60 nm) was used as an anode (lower electrode). Then, the device separation film was patterned by exposing with a UV lamp followed by development, whereby opening portions were formed.

[0053] The device substrate thus obtained was cleaned with an aqueous solution of a surfactant, and rinsed with ion exchanged water and ultrasonic waves.

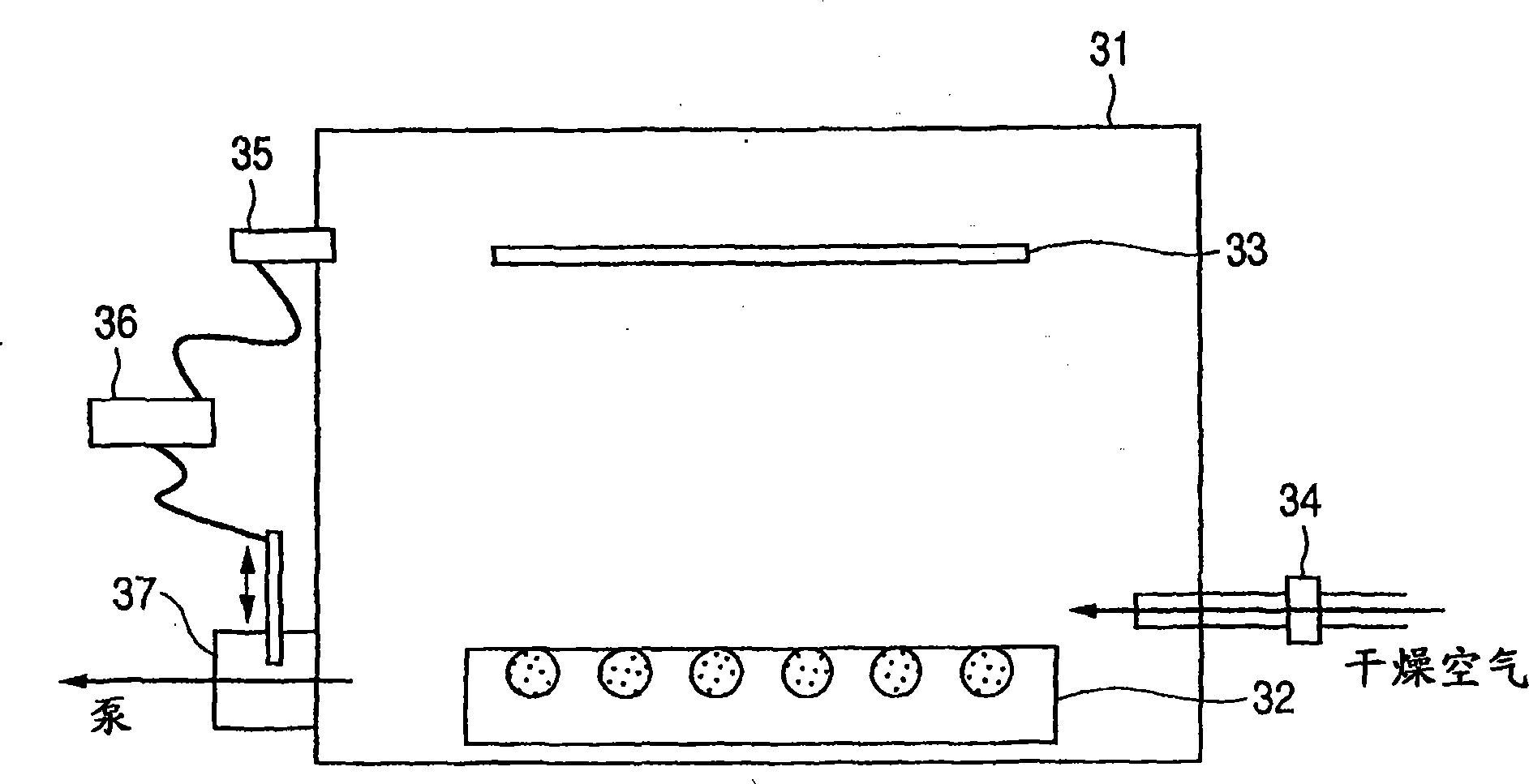

[0054] The cleaned device substrate was placed in a vacuum dryer to perform dehydration at 200° C. for 24 hours.

[0055] The device substrate subjected to dehydration was introduced into a substrate pretreatment apparatus, opposed to a low-pressure mercury lamp (output: 110 W), and was shaken at a rate of 20 mm / sec within a range of 50 mm intervals. The shortest distance between lamp and substrat...

example 2

[0064] A device substrate was fabricated in the same manner as in Example 1 except that a Cr film having a thickness of 100 nm was used as an anode, followed by cleaning and dehydration. Further, as a treatment before forming the organic EL layer, UV ozone treatment was performed in the same manner as in Example 1 except that the ambient pressure was set to 100 Pa.

[0065] The obtained organic light-emitting device was evaluated in the same manner as in Example 1, and it was found that L(100h) / L(ini) was 94.5% (initial illuminance L(ini)=1,050 cd / m 2 ), and the organic light-emitting device has excellent driving and lifetime characteristics, the same as Example 1. In addition, the luminescent state after being left at a temperature of 80° C. and a humidity of 80% for 1000 hours was the same as in the case before being left.

example 3

[0067] An organic light-emitting device was manufactured in the same manner as in Example 1, using the device substrate used in Example 1, except that the pressure during the process before forming the organic EL layer was 10000 Pa.

[0068] The obtained organic light-emitting device was evaluated in the same manner as in Example 1, and it was found that L(100h) / L(ini) was 92.8% (initial illuminance L(ini)=1,290cd / m 2 ), and the organic light-emitting device has excellent driving and lifetime characteristics, although slightly worse than those in Example 1. In addition, the luminescent state after being left at a temperature of 80° C. and a humidity of 80% for 1000 hours was the same as in the case before being left.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com