Dispensing needle wiping device of voice coil motor production equipment

A technology of production equipment and voice coil motor, which is applied to the surface coating liquid device, spray device, coating, etc., which can solve the problems affecting the quality of dispensing and reducing the rate of good products, so as to reduce defective products and improve production efficiency ,Easy to erase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

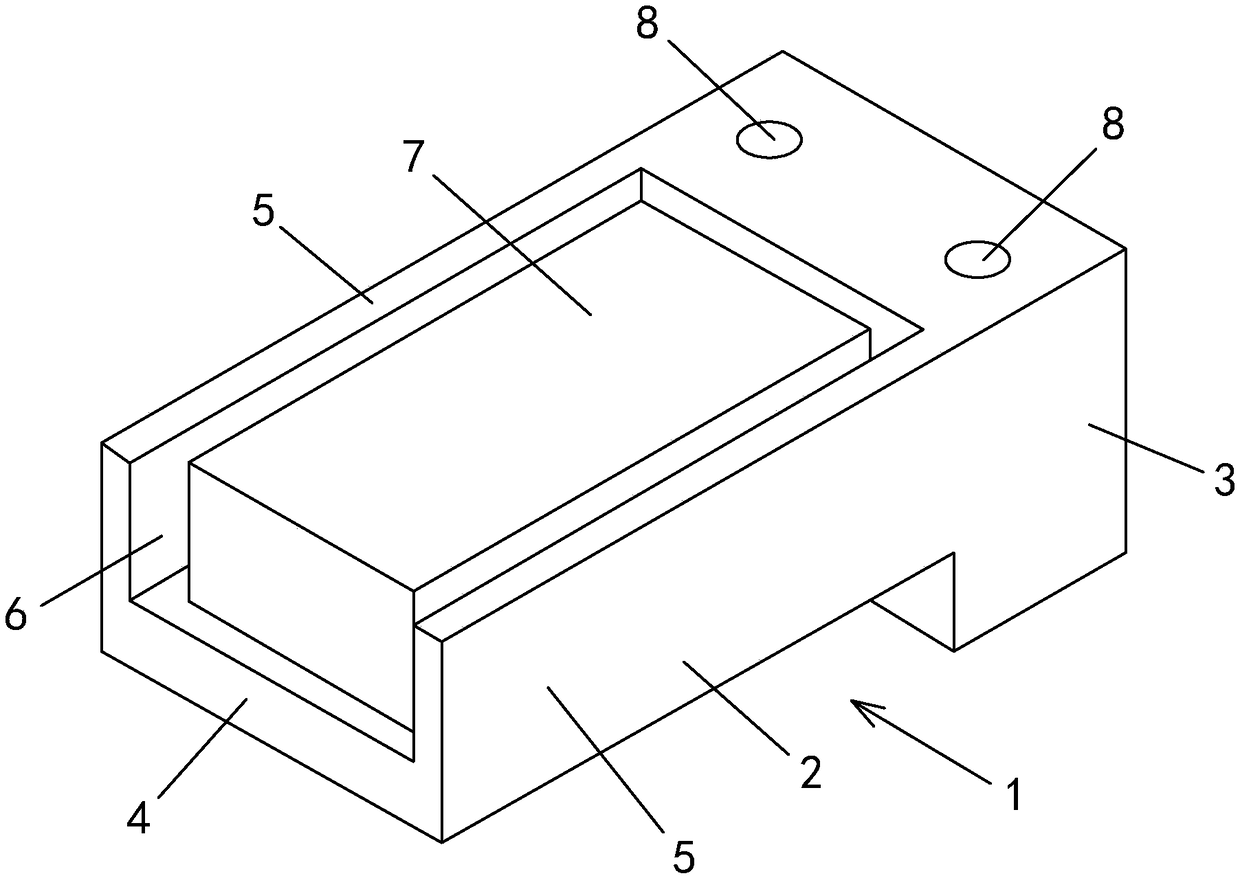

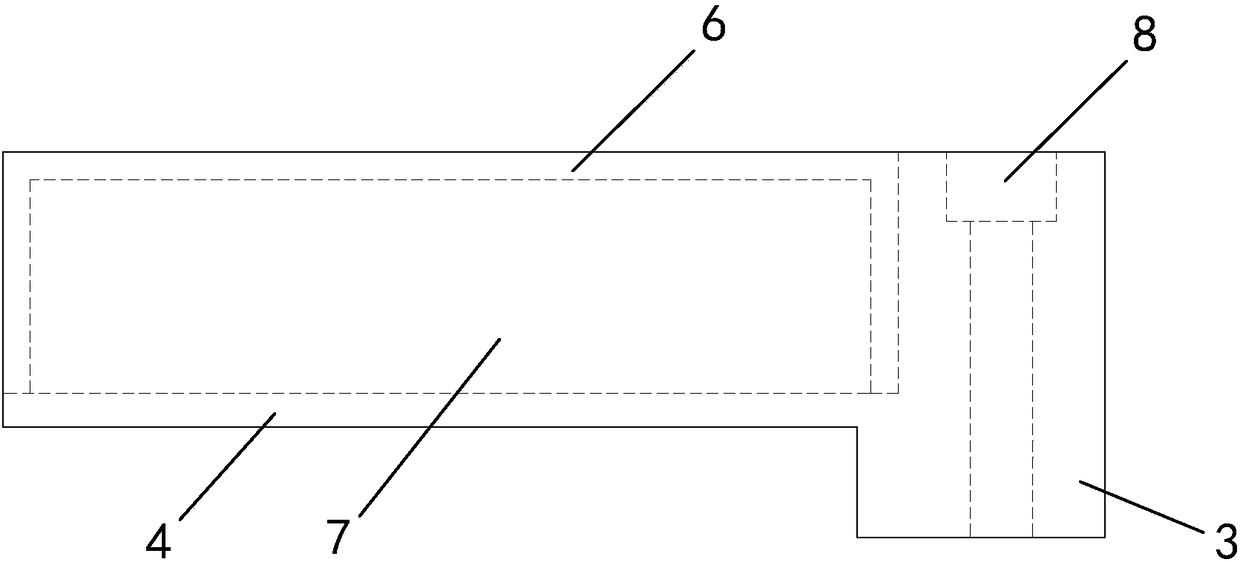

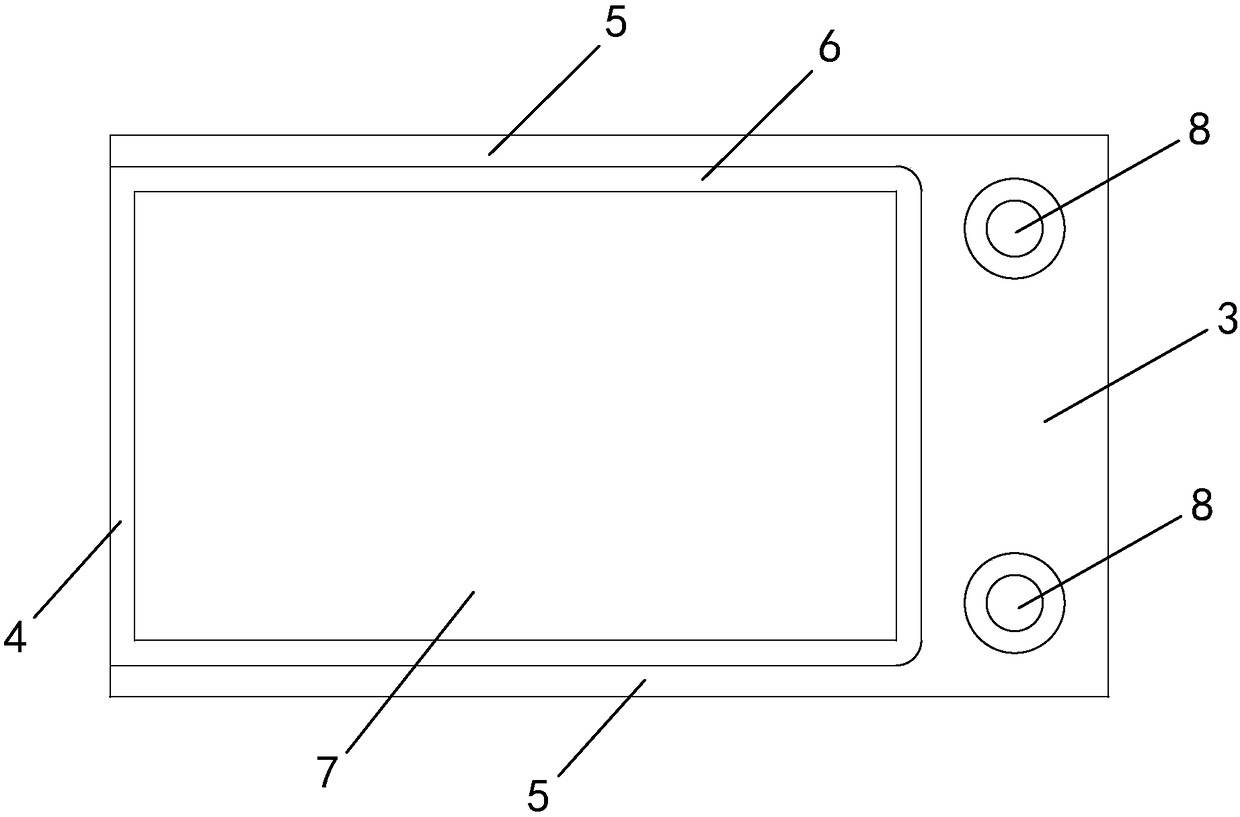

[0023] Example: see attached Figure 1~3 As shown, a dispensing needle wiping device for voice coil motor production equipment includes a connecting block 1, the connecting block 1 includes a wiping part 2 at the front end and a positioning part 3 at the rear end, and the two parts are integrally formed.

[0024] Wherein, the wiping part 2 includes a base plate 4 and two side plates 5; the base plate 4 is arranged in the horizontal direction and is located at the bottom of the wiping part 2; the two side plates 5 are arranged in the vertical direction and are located in the The two sides of the wiping part 2; the two side plates 5 are respectively connected under the left and right sides of the bottom plate 4, and the three jointly define and form an accommodating groove 6, the front end and the upper end of the accommodating groove 6 They are all open to facilitate the entry of the dispensing needle; a wiping body 7 is positioned in the accommodating groove 6 for wiping the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com