Plastic pipe broaching device

A technology for plastic pipe fittings and valve bodies is applied in the field of reaming devices for plastic pipe fittings, which can solve the problems of high cost and complex structural design, and achieve the effects of high work efficiency and novel structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

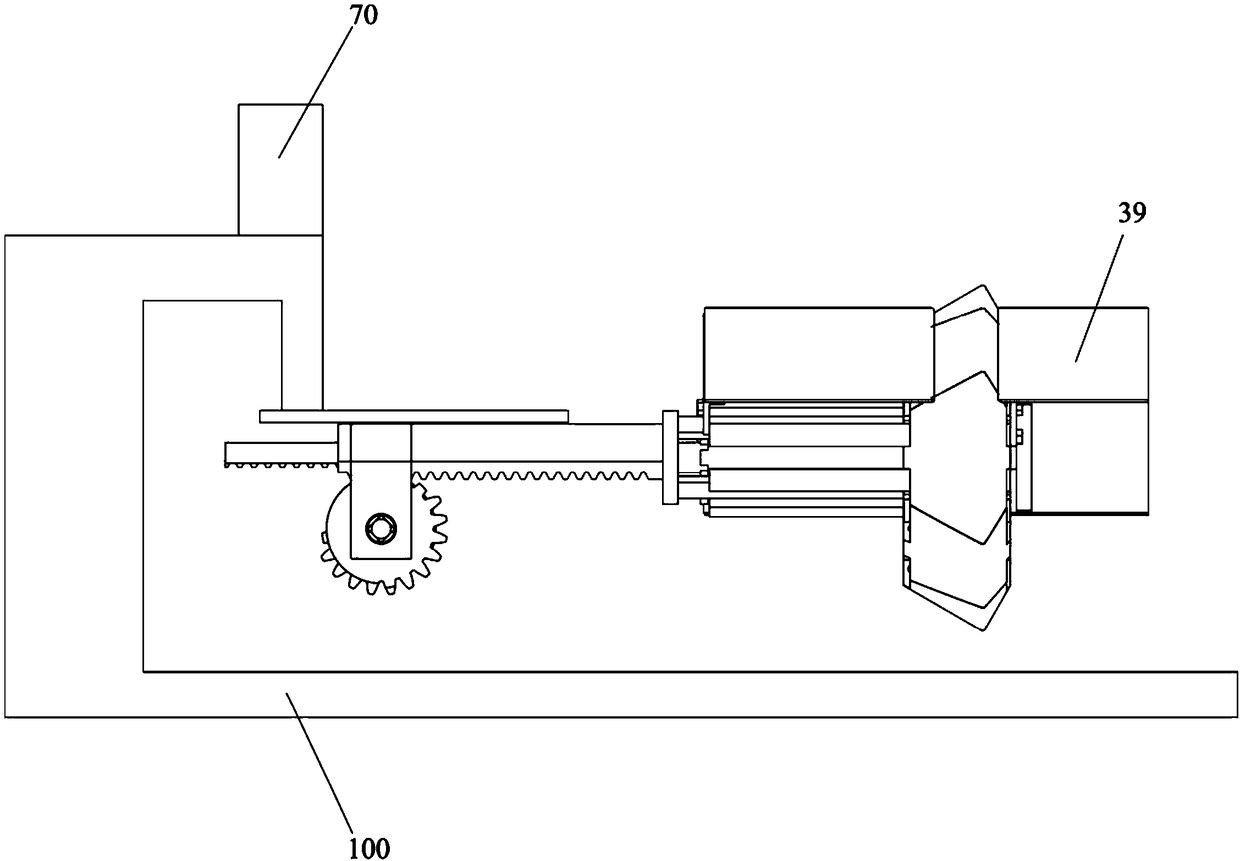

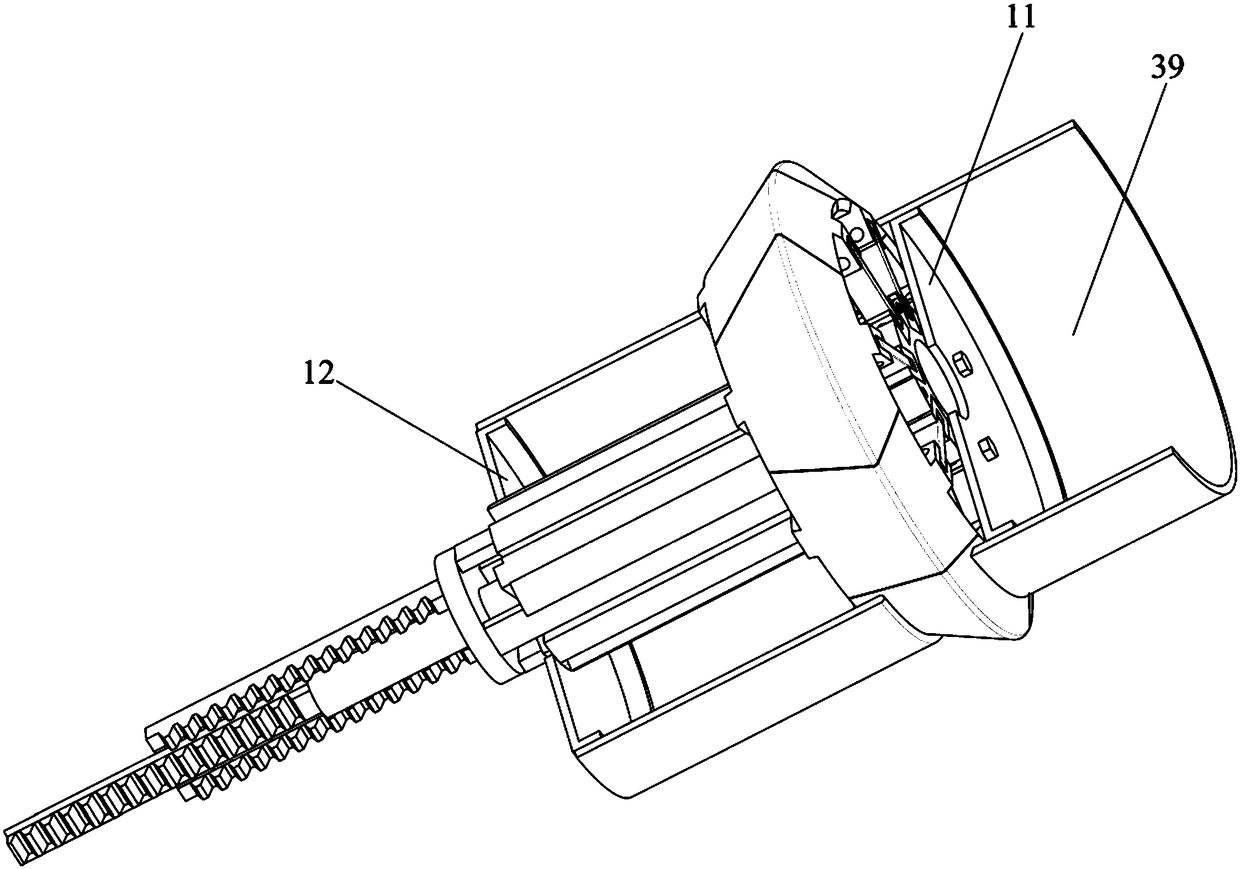

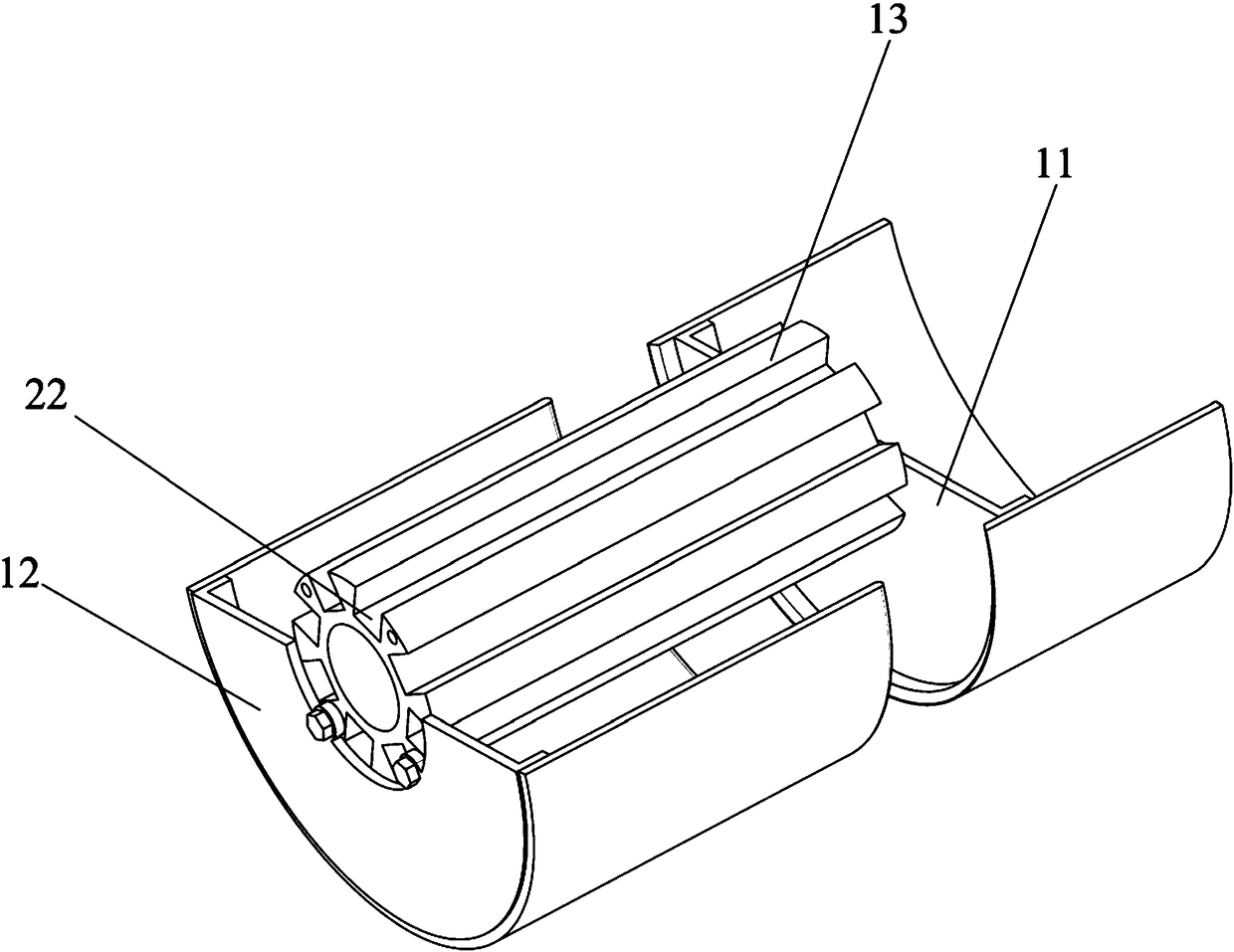

[0027] Such as Figure 1 to Figure 8 As shown, the present invention provides a plastic pipe reaming device, comprising a frame 100, a front cover 11, a rear cover 12, a fixed cylinder 13, a connecting plate 14, a connecting frame 15, a first reaming valve body 16, a second The reaming petal body 17, the front cover 11 and the rear cover 12 are connected by a fixed cylinder 13, the rear cover 12 is fixed on the frame 100, and the two sides of the connection plate 14 are respectively connected to the first rack 18 and four racks. A first slide bar 19, the two sides of the connecting frame 15 are respectively connected to the guide post 20 and four second slide bars 21, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com