Printing device and conveying device

A technology for printing devices and conveying devices, applied in printing devices, printing, typewriters, etc., can solve the problems of reduced suction force of media, achieve the effect of ensuring suction force and expanding the suction range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

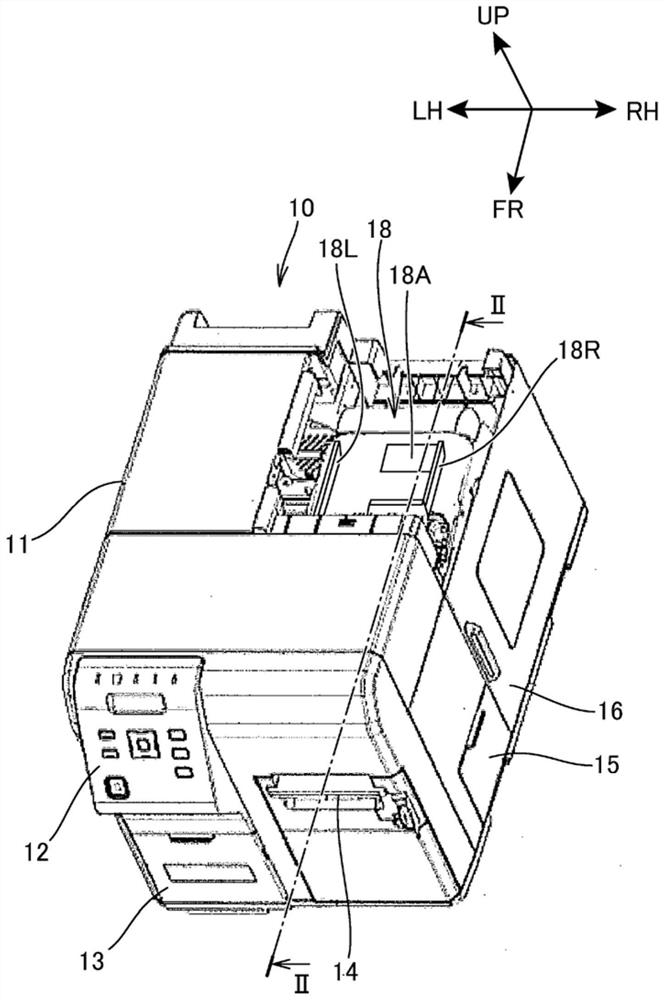

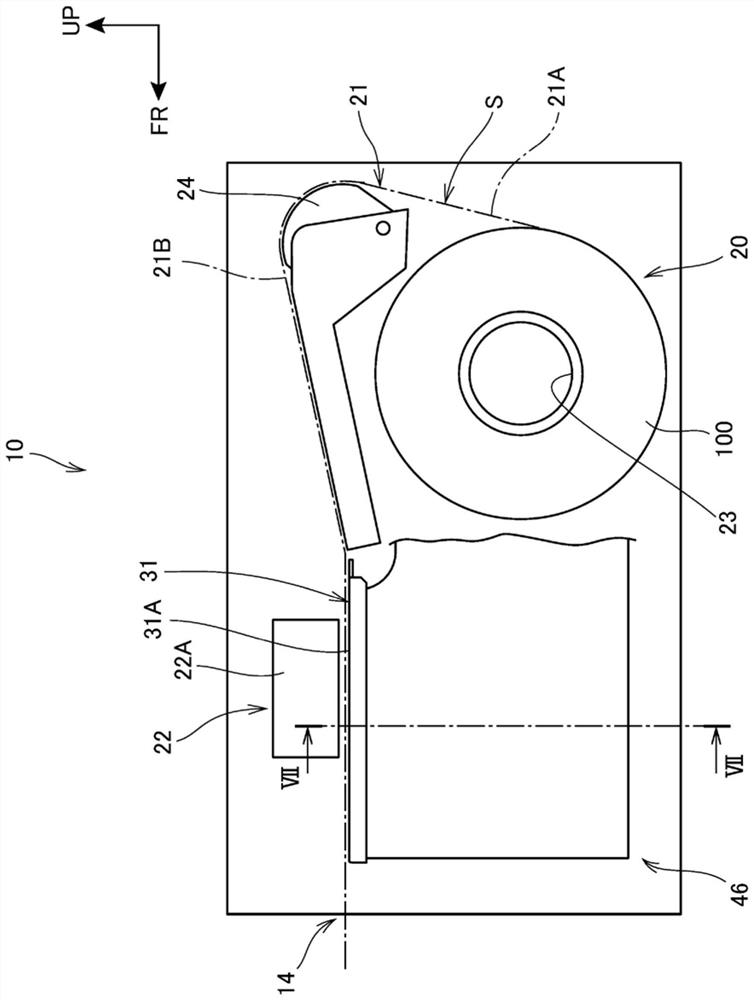

[0034] figure 1 It is a diagram showing the appearance of the printing device 10 according to the first embodiment of the present invention.

[0035] The printing device 10 is a printer that prints on continuous paper S (recording medium, medium) such as label paper formed by attaching labels to elongated backing paper at constant intervals, and is also called a label printer. The printing device 10 is wired or wirelessly connected to an information processing terminal via a USB (Universal Serial Bus) cable or a LAN (Local Area Network) Print data to implement printing.

[0036] exist figure 1 In each figure described later, the symbol FR represents the front of the printing device 10 , the symbol LH represents the left side of the printing device 10 , the symbol RH represents the right side of the printing device 10 , and the symbol UP represents the upper side of the printing device 10 .

[0037] Such as figure 1 As shown, the printing device 10 has a rectangular paralle...

no. 2 approach

[0119] The printing apparatus 10 according to the second embodiment differs from the printing apparatus 10 in that it includes a guide unit 18 for conveying the continuous paper S at the center and in a part of the suction holes 51 that suck the platen 31 . The first embodiment is the same. In addition, the guide unit 18 which is placed in the center and carries out conveyance only needs to apply a well-known guide unit, and the description is abbreviate|omitted.

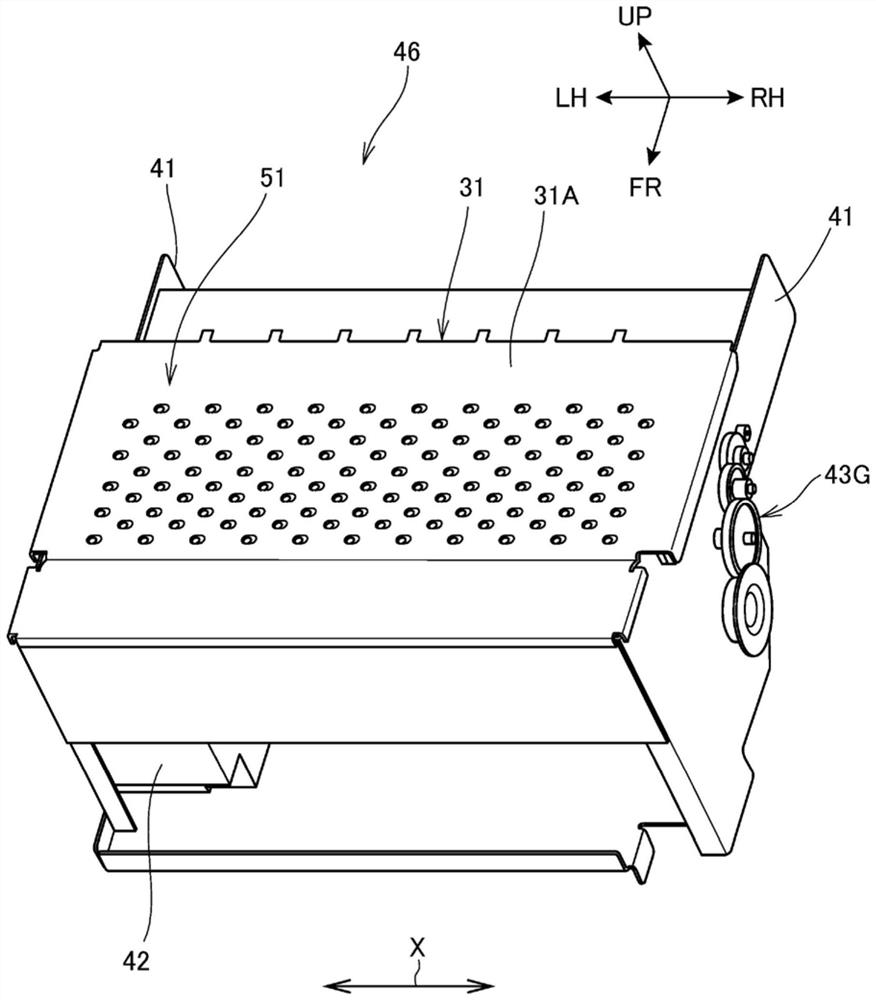

[0120] Figure 12 It is a figure which looked at the suction platen 31 of the printing apparatus 10 which concerns on 2nd Embodiment from above. Since the guide unit 18 centers and conveys the continuous paper S, the center LC of the continuous paper S on the suction platen 31 is always the same.

[0121] Such as Figure 12 As shown, the suction platen 31 is provided with a first suction hole 51A and a second suction hole 51B as a plurality of suction holes 51, wherein the first suction hole 51A is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com