Safe and environment-friendly plate cutting machine for sports equipment machining

A kind of sports equipment, safety and environmental protection technology, applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc. The effect of spattering and hurting people, reducing equipment cost and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

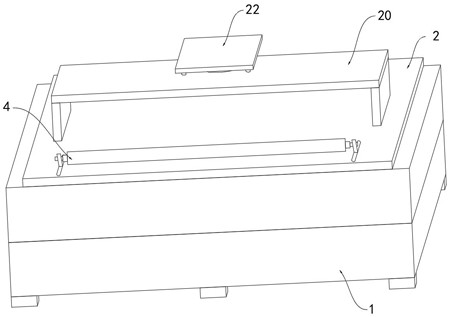

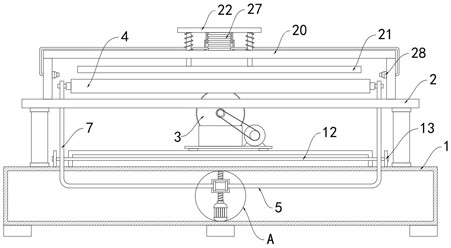

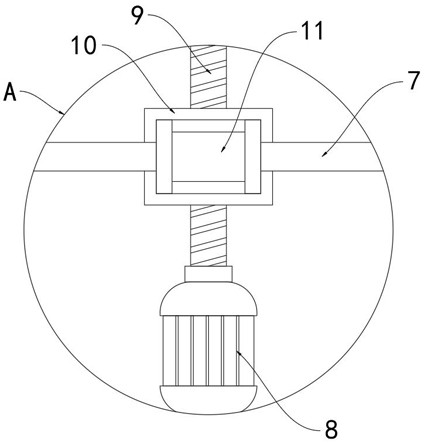

[0032] Such as Figure 1-7 As shown, a safe and environment-friendly sports equipment processing board cutting machine includes a base 1, a cutting platform 2 is arranged on the base 1, a cutting machine 3 is arranged below the cutting platform 2, and a cutting machine for driving cutting is arranged under the cutting machine 3. The slide rail that the machine 3 moves longitudinally, through the longitudinal movement of the cutting machine 3, cuts the plate on the cutting platform. This is the prior art, and will not be described here. 1 is provided with an adjustment mechanism 5 for adjusting the position of the side pressure rod 4, and the side pressure rod 4 is provided with a suction mechanism 6 for collecting cutting waste;

[0033] Further, the adjustment mechanism 5 includes two U-shaped struts 7, and the upper ends of the two U-shaped struts 7 are respectively fixedly connected to the two ends of the two side pressure rods 4, the base 1 is provided with a drive motor 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com