Generator rotor automatic feeding mechanism

A generator rotor and automatic feeding technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of low automation and achieve the effect of a reasonable and compact structure of the positioning mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

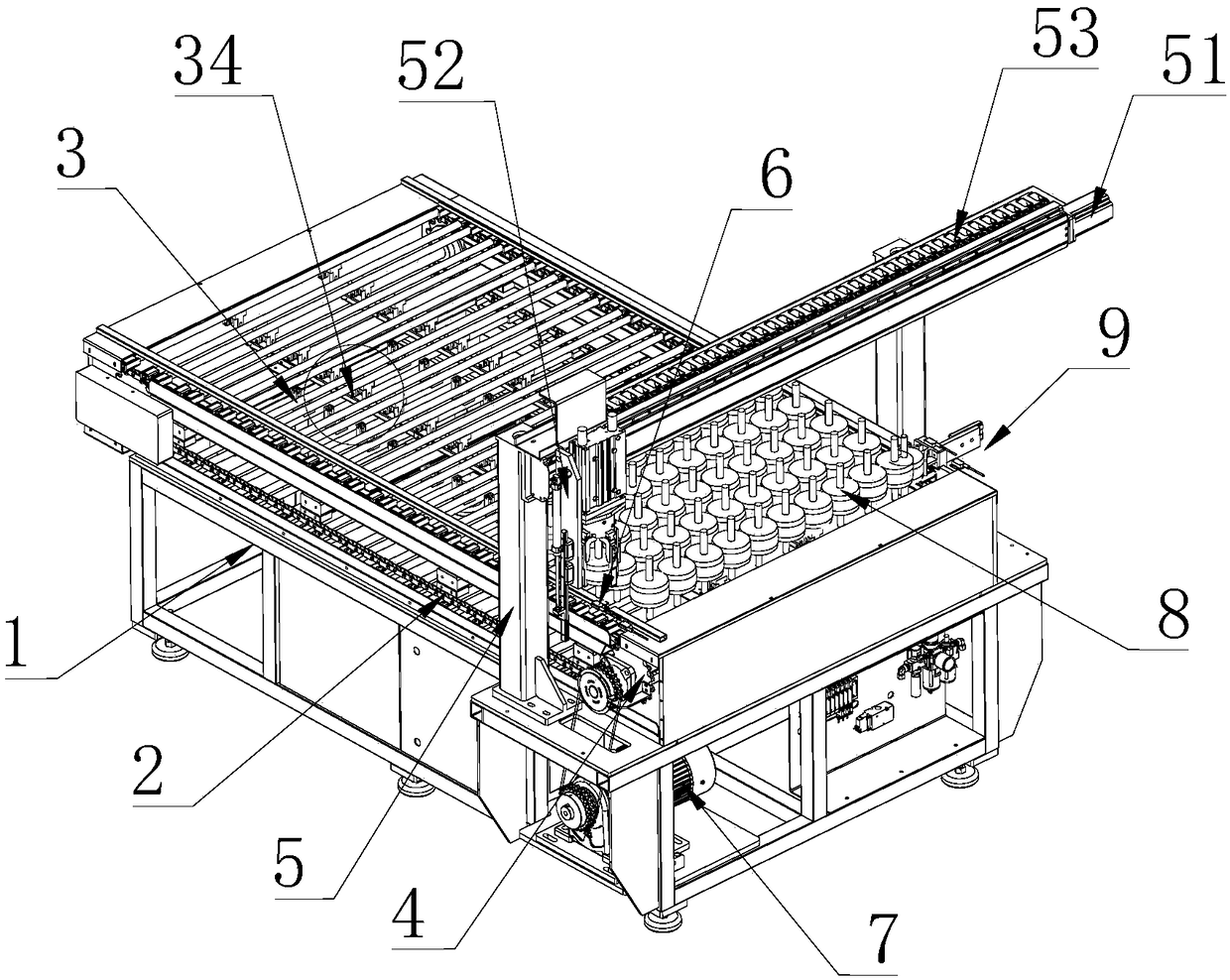

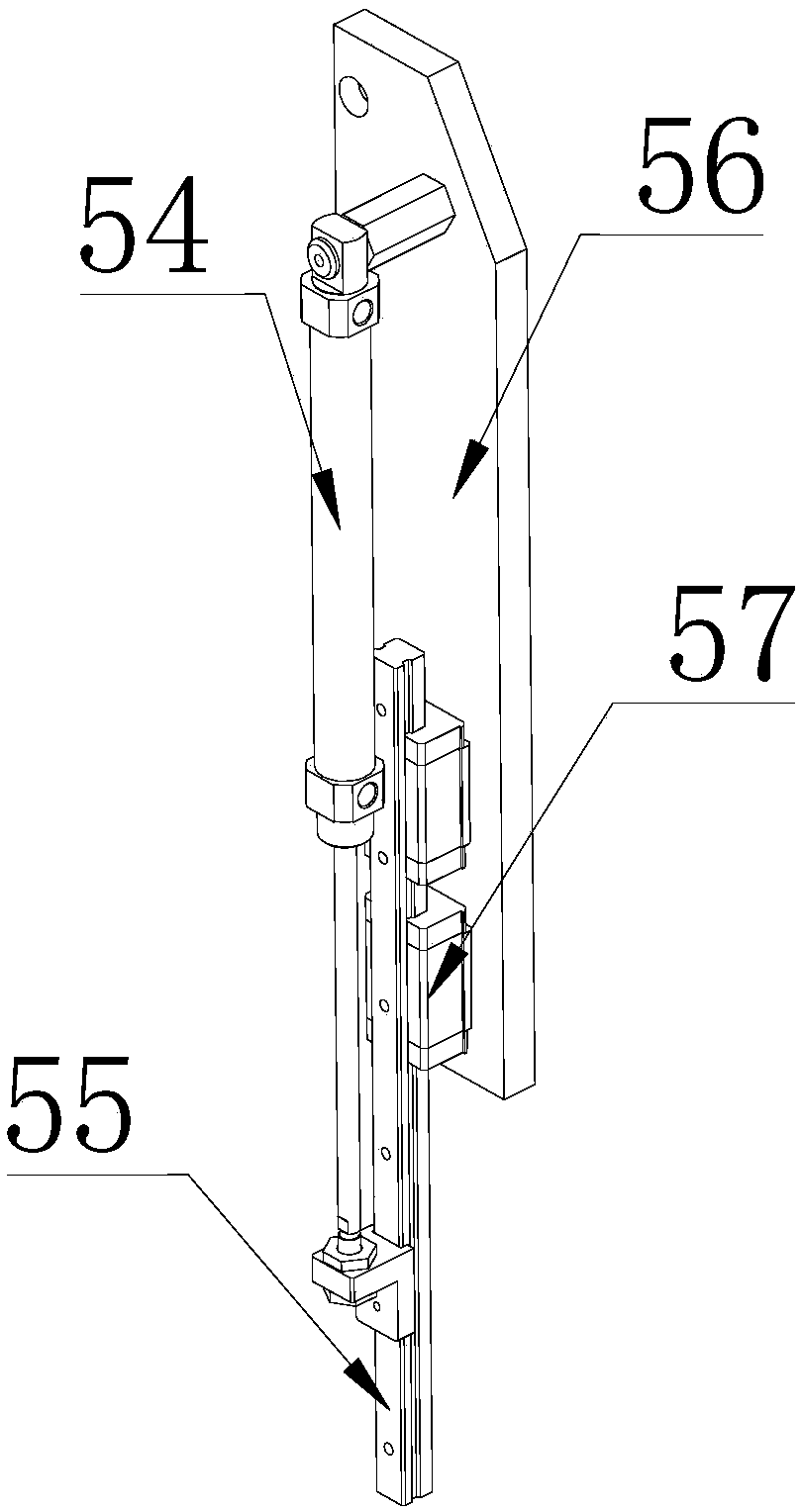

[0029] combine Figure 1 to Figure 6 , to describe this embodiment in detail. An automatic feeding mechanism for a generator rotor 8 involved in this embodiment includes a conveying mechanism and a positioning mechanism 9 .

[0030] The longitudinal moving device of the rotor 8 includes a chain 2 fixed on the frame 1 and several rotor supporting devices 3 fixedly connected to the chain 2 . The number of chains 2 is two, which are respectively located on both sides of the frame 1. The two ends are respectively connected by a sprocket 4. The second motor 7 drives the chain 2 through the sprocket 4 at one end, and the sprocket 4 at the other end is driven.

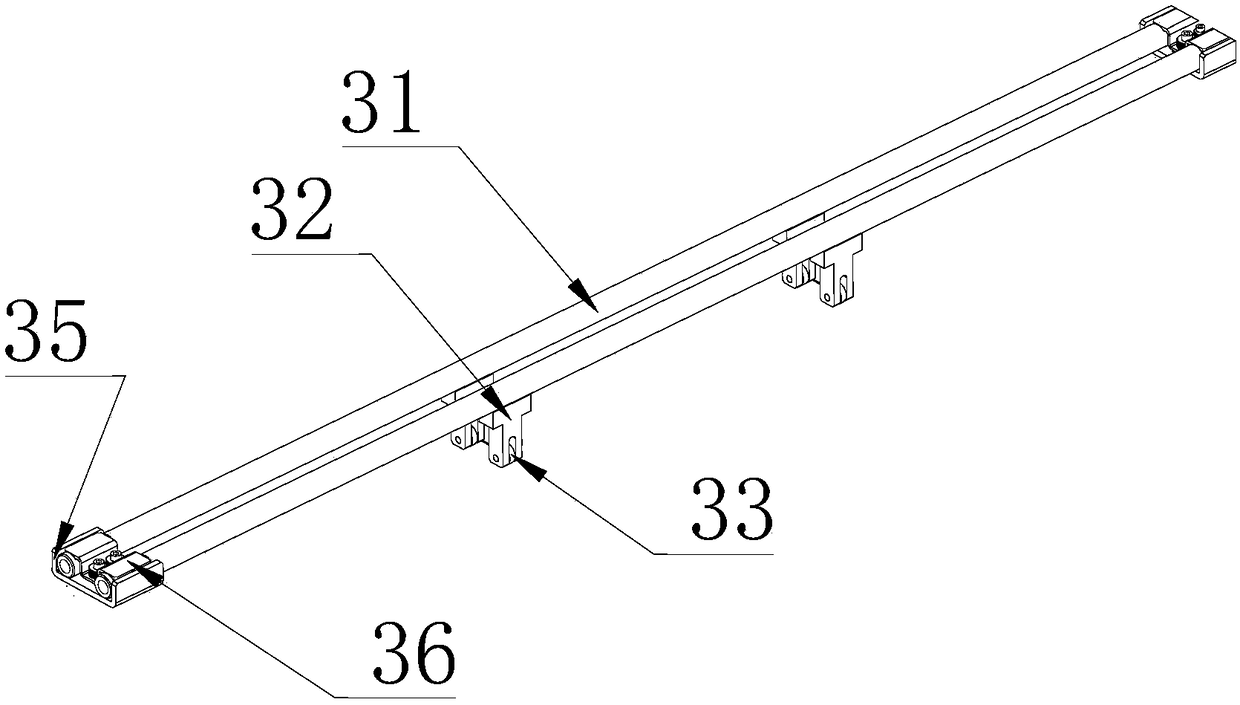

[0031] One chain 2 is fixed to one end of the rotor supporting device 3, and the other chain 2 is fixed to the other end of the rotor supporting device 3. The fixing is through a U-shaped plate 35, a folded plate 36 and two bolts. The folded plate 36 and the U-shaped plate 35 form a cavity that can fix the support rod 31. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com