A non-contact pneumatic broom type hot-dip galvanizing system for strip steel

A non-contact, hot-dip galvanizing technology, applied in the hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problem that the surface roughness of the strip steel has a great influence on the quality, the principle process does not change, scratches, etc. problems, to achieve the effect of reducing the surface scratch rate and the scrap rate of coiled strip steel, avoiding principle defects, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

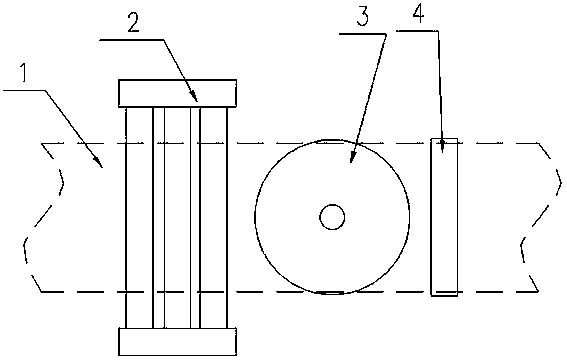

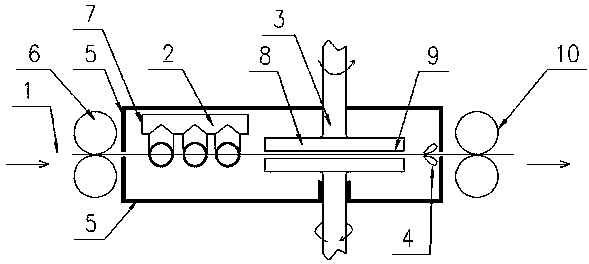

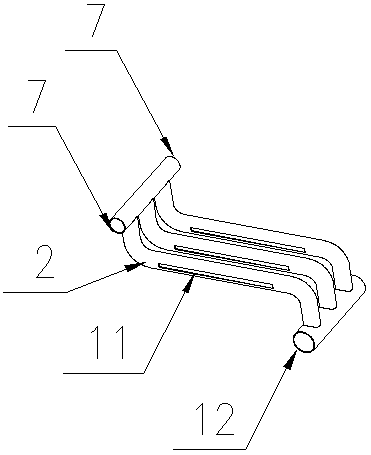

[0017] Such as Figure 1 to Figure 5 A non-contact pneumatic broom-type hot-dip galvanizing system for strip steel shown includes two entrance stabilizing rolls 6 and two exit stabilizing rolls 10, and an insulation cover 5 is arranged between the entrance stabilizing rolls 6 and the exit stabilizing rolls 10. The inlet side and the outlet side of the cover 5 are respectively provided with horizontal slits, and the inside of the heat preservation cover 5 is provided with a galvanized tube group 2 near the inlet side. It communicates with the residual zinc outlet 7, and the lower part of the galvanizing pipe is connected with the zinc liquid inlet 12. The two sides of the middle part of each galvanizing pipe are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com