Screeding system using infrared rays and using method thereof

An infrared and rib technology, applied in construction, building structure, etc., can solve problems such as delay time, waste of human resources, line falling and shaking, etc., and achieve the effects of precise construction, convenient operation, and clear and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

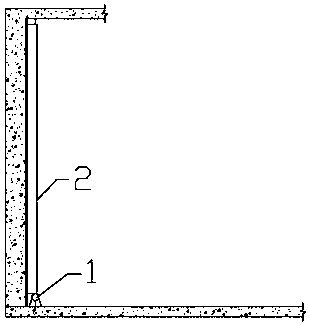

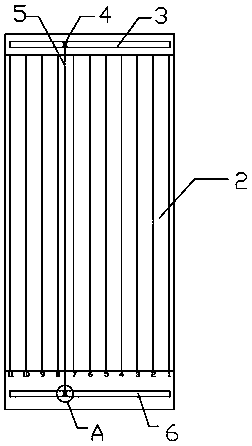

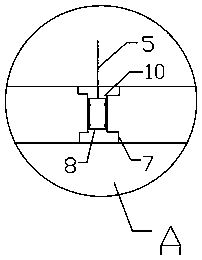

[0029] Example 1: as Figures 1~5 As shown, a rib punching system using infrared rays includes an infrared level 1, a ruler rod 2, and a cutting line 11. The upper end of the ruler rod 2 is provided with an upper chute 3, and an upper slider 4 is movably installed in the upper chute 3. The slider 4 is fixedly connected with one end of the positioning line 5, and the lower part of the ruler rod 3 is provided with a lower sliding groove 6, and a lower sliding block 7 is movably installed in the lower sliding groove 6, and the lower sliding block 7 is provided with a knife groove 10. The cutter 8 is fixedly connected, and the cutter 8 is movably installed in the slot 10 .

Example Embodiment

[0030] Embodiment 2: a kind of punching system using infrared rays, comprising an infrared level 1, a ruler rod 2, a cutting line 11, an upper chute 3 is provided on the upper end of the ruler rod 2, and an upper slider 4 is movably installed in the upper chute 3, The upper slider 4 is fixedly connected with one end of the positioning line 5, the lower part of the ruler rod 3 is provided with a lower slot 6, the lower slider 7 is movably installed in the lower slot 6, the lower slider 7 is provided with a knife slot 10, and the other end of the positioning line 5 It is fixedly connected with the cutter 8, the cutter 8 is provided with a slot I9, the cutter slot 10 is provided with a raised block matched with the slot I9, and the cutter 8 is movably installed in the slot 10.

Example Embodiment

[0031] Embodiment 3: a kind of punching system using infrared rays, comprising an infrared level 1, a ruler rod 2, a cutting line 11, an upper chute 3 is provided on the upper end of the ruler rod 2, and an upper slider 4 is movably installed in the upper chute 3, The positioning line 5 includes two steel wires. One end of the steel wire is fixedly connected with the upper slider 4, and the other end of the steel wire is fixedly connected with the lower slider 7. Two rows of rings are installed on the cutter 8, and the cutter 8 passes through the two lines. The row of circular rings is slidably installed on the two steel wires, and other structures are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap