Hypersonic-speed variable-cross-section inward rotation type air feeding channel quick design method capable of achieving full flow capture

An internally rotating inlet and hypersonic technology, applied in the direction of computing, mechanical equipment, jet propulsion devices, etc., can solve the problems of complex implementation process and long design cycle, and achieve simple design process, shorten design cycle, and easy software The effect of automated design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

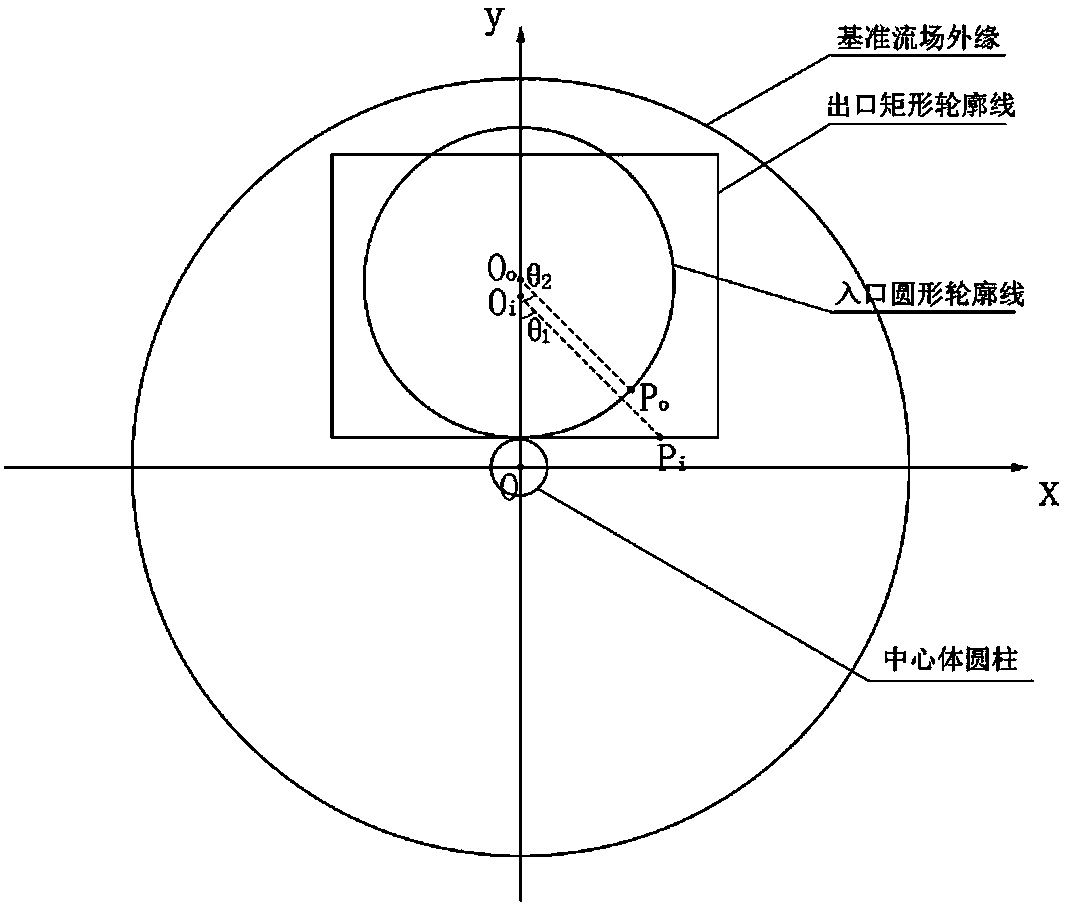

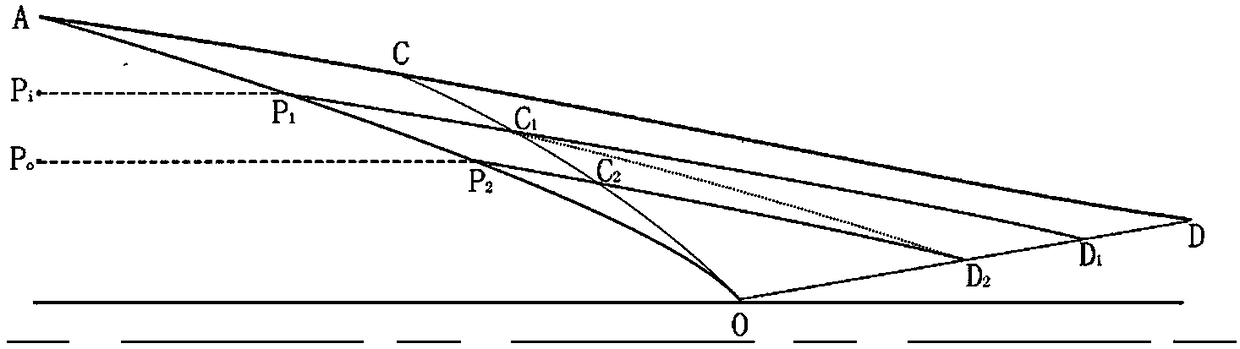

[0053] refer to Figure 1 to Figure 6 , the inlet of the inner-turning inlet is selected as a rectangle, and the outlet is a circle. The detailed steps are described:

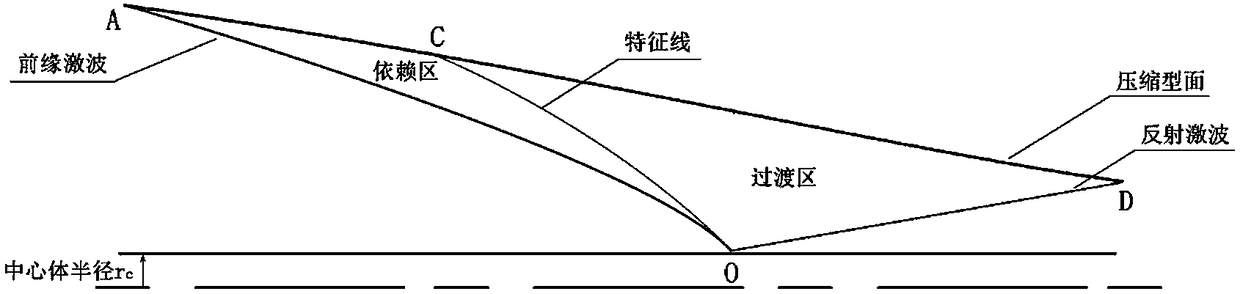

[0054] Such as figure 1 As shown in , it is a schematic diagram of the processing method of a given reference flow field, which is divided into a dependent region and a weighted transition region by characteristic lines.

[0055] For the reference flow field and incoming flow parameters of the known compression profile and center body radius, the characteristic line method is used to calculate the flow conditions of the reference flow field, and the leading edge shock wave, tail shock wave, also called reflected shock wave, and forward shock wave are obtained. The characteristic line of the intersection point of the marginal shock and the central body. The characteristic line OC divides the reference flow field into two regions, the dependent region and the weighted transition region.

[0056] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com