Wire repairing device and robot for transmission line and application methods of wire repairing device and robot

A technology for power transmission lines and robots, applied in the direction of clip connection conductor connection, clamp/spring connection, etc., can solve the problems of high labor intensity, high risk, long time, etc., and achieve the effect of improving work efficiency and automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

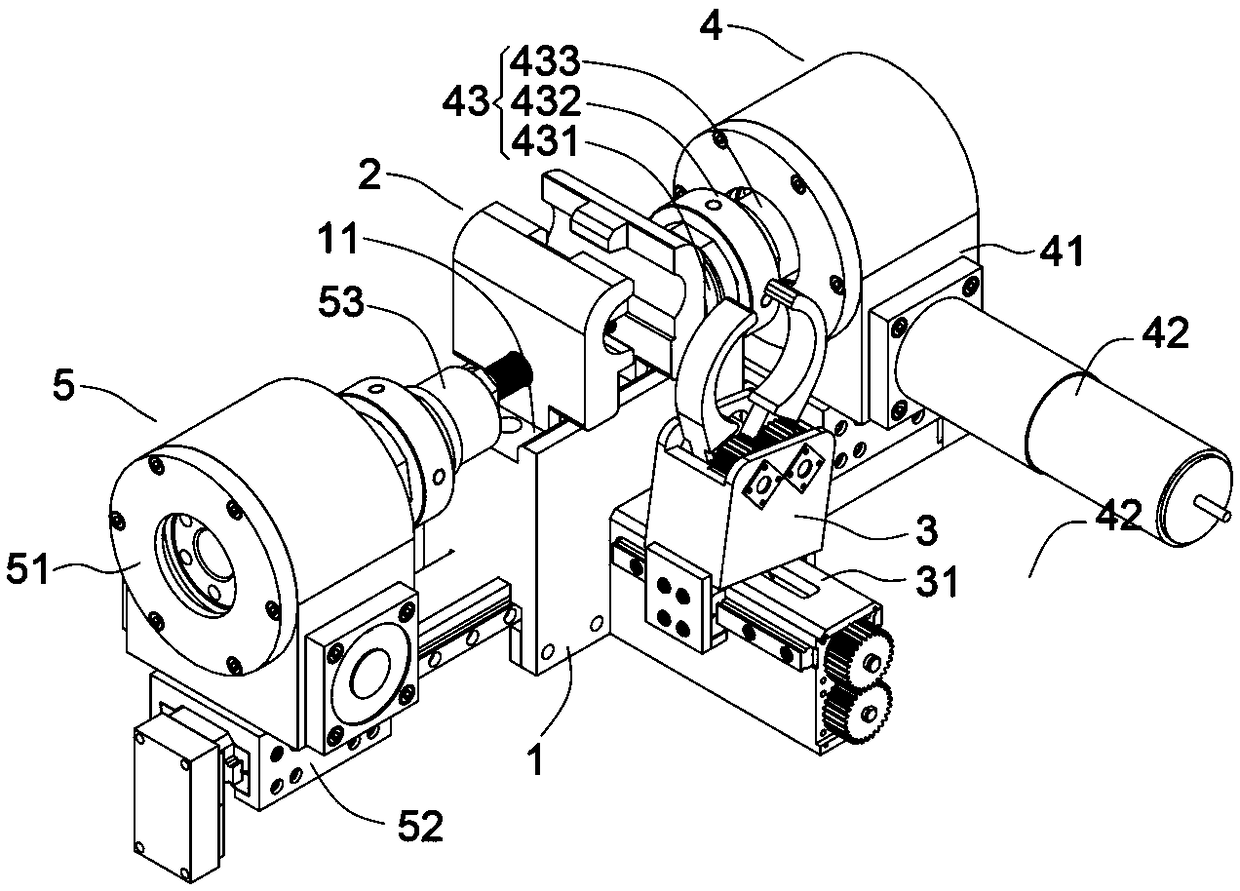

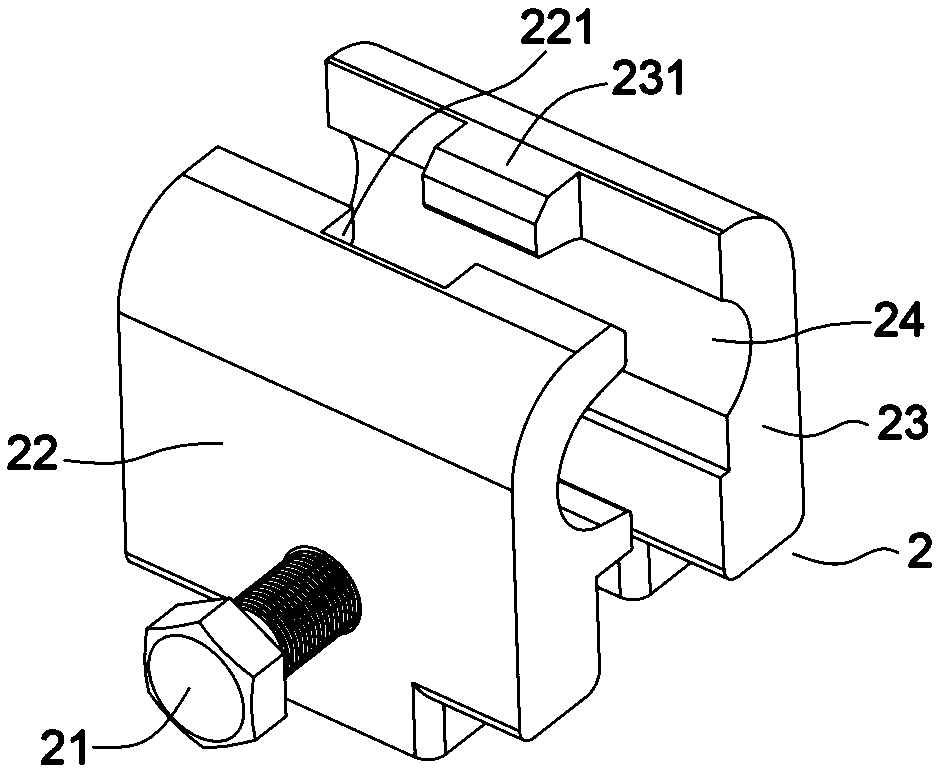

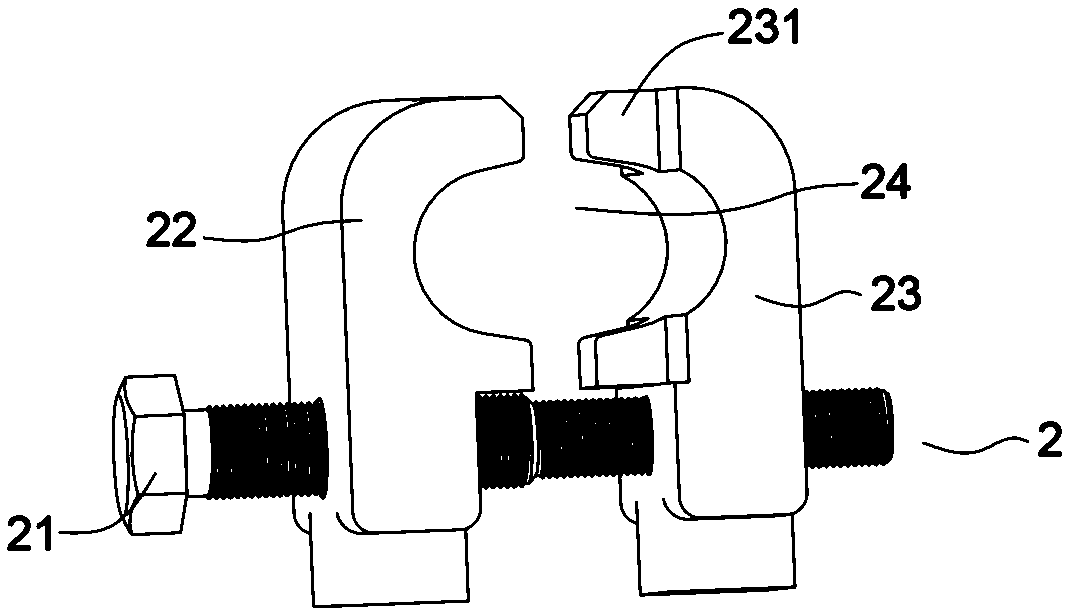

[0037] Such as figure 1 , figure 2 and image 3 As shown, the transmission line conductor repairing device of the present embodiment includes a clamping platform 1 and a clamping repair assembly 2 and a threading assembly 3 respectively arranged on the clamping platform 1. The clamping platform 1 is provided with a guide groove 11, and the clamping The wire repair assembly 2 includes a clamping bolt 21, a first clamping block 22 and a second clamping block 23, the clamping bolt 21 passes through the first clamping block 22 and the second clamping block 23 respectively, and is forwardly threaded with the first clamping block 22 Cooperate with the reverse thread of the second clamping block 23 (the first clamping block 22 and the second clamping block 23 can be clamped or loosened by the positive and negative rotation of the clamping bolt 21), the first clamping block 22 and the second clamping The lower part of the block 23 slides in the guide groove 11 (for fixing the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com