Parameter self-adaptive adjusting method and device

A self-adaptive adjustment and parameter technology, applied in control/adjustment systems, non-electric variable control, instruments, etc., can solve the problems of high labor cost, high labor intensity, untimely adjustment, etc., to improve accuracy and timeliness, The effect of improving the quality of pellets and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

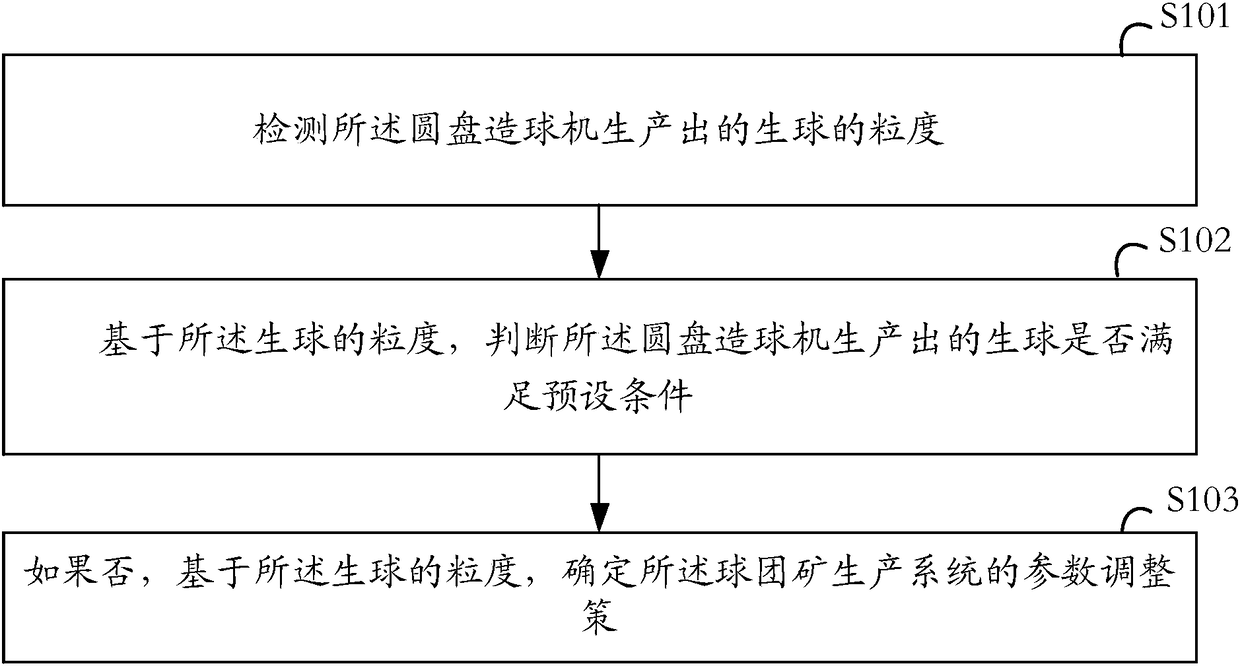

[0071] Please refer to figure 1 , A parameter adaptive adjustment method in the first embodiment of the present invention is applied to a pellet production system, the pellet production system includes a disc pelletizer, and the method includes:

[0072] S101: Detect the particle size of the green balls produced by the disc pelletizer;

[0073] S102: Based on the particle size of the green balls, determine whether the green balls produced by the disc pelletizer meet a preset condition;

[0074] S103: If not, determine the parameter adjustment strategy of the pellet production system based on the particle size of the green pellets.

[0075] Wherein, the adjustment parameters corresponding to the parameter adjustment strategy include any one or a combination of: pelletizing water replenishment amount, rotating speed of pelletizing machine, and pelletizing feed amount.

[0076] Specifically, in this embodiment, the pellet production system includes a disc pelletizer, and a set of green bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com