A kind of high temperature annealing method of patterned thin film

A patterned film and high-temperature annealing technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as cracking of patterned films, achieve good shape, simple process, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment is used to illustrate the high temperature annealing method of the patterned thin film disclosed in the present invention.

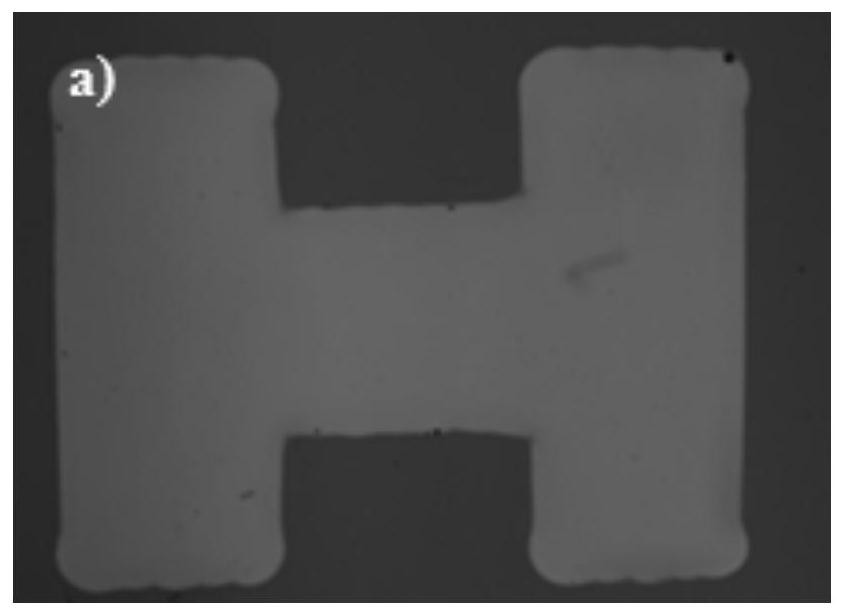

[0038] (1) In N-type Si / SiO 2 High-precision inkjet printing equipment is used to print patterned film liquid, in which the solvent is ethylene glycol methyl ether, and the film-forming material is indium zinc oxide. Observing the patterned film liquid through a ZEISS optical microscope, it is in a liquid state, such as Figure 1a shown.

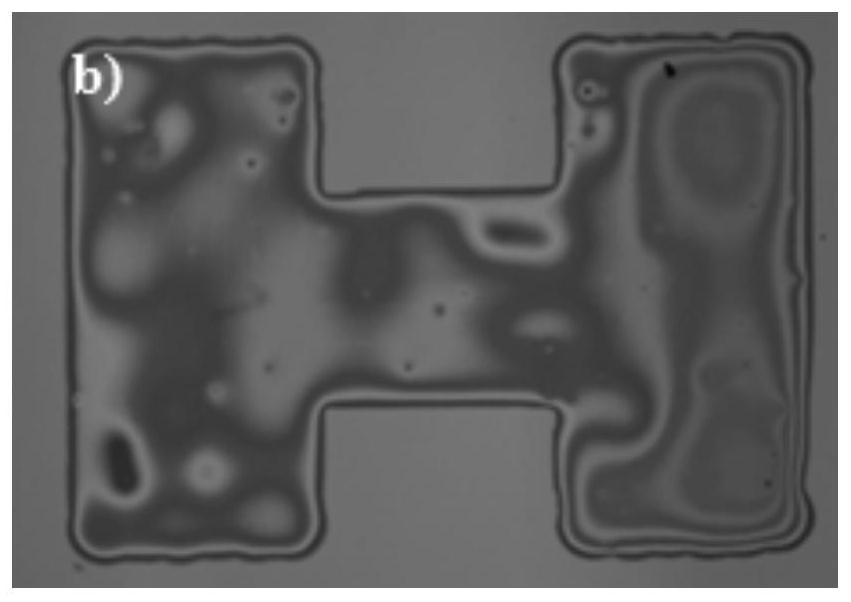

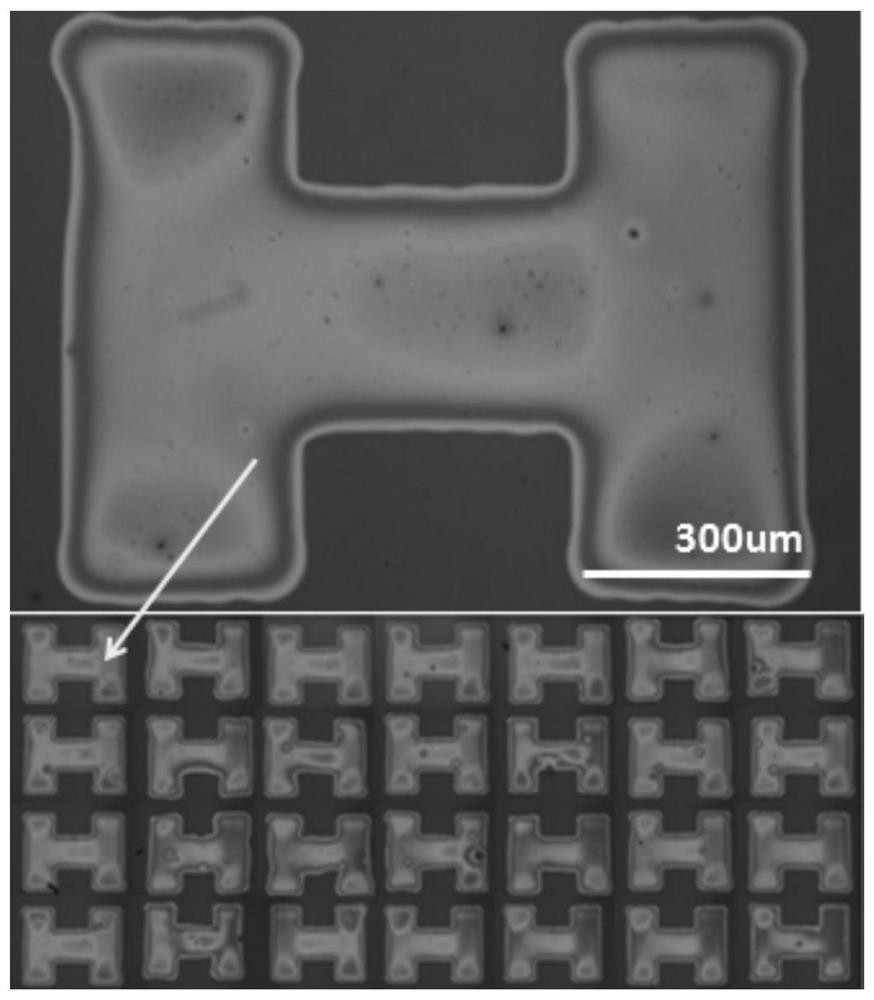

[0039] (2) Set the pre-annealing temperature to 120°C. The temperature was raised to 120° C. at a heating rate of 5° C. / min, and maintained in an air environment for 1 hour, and a pre-annealing treatment was performed on the patterned film solution to obtain a film precursor. Observation by ZEISS optical microscope shows that after the pre-annealing treatment, the morphology of the micropattern has begun to solidify and is no longer in a liquid state, such as Figure 1b shown.

[0040] (3) Se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com